Preloading bolt assembly equipment and method

A technology for assembling equipment and bolts, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem that the bolt tightening mechanism cannot exist at the same time, and achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

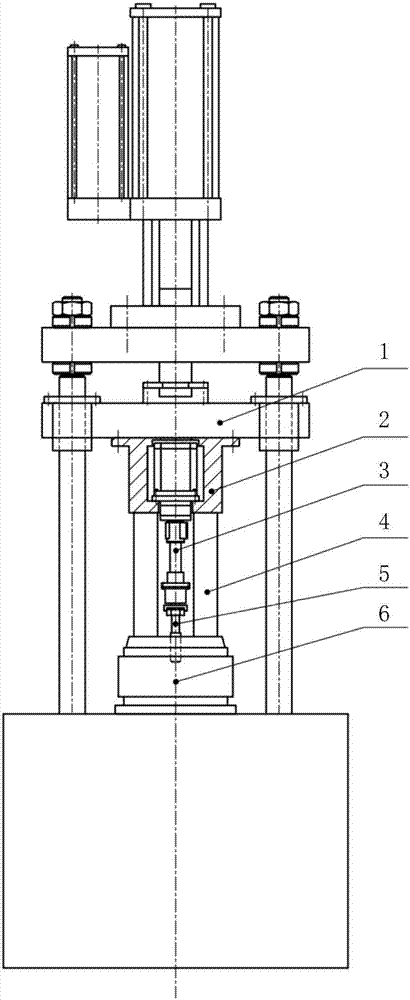

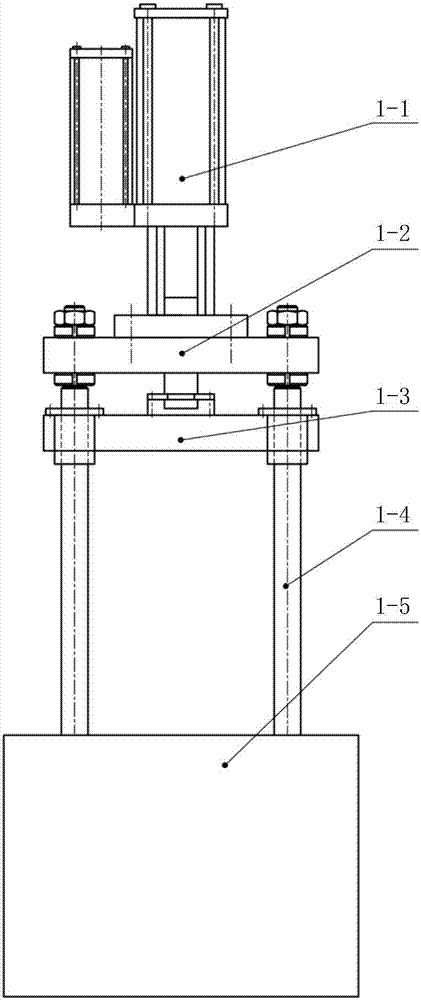

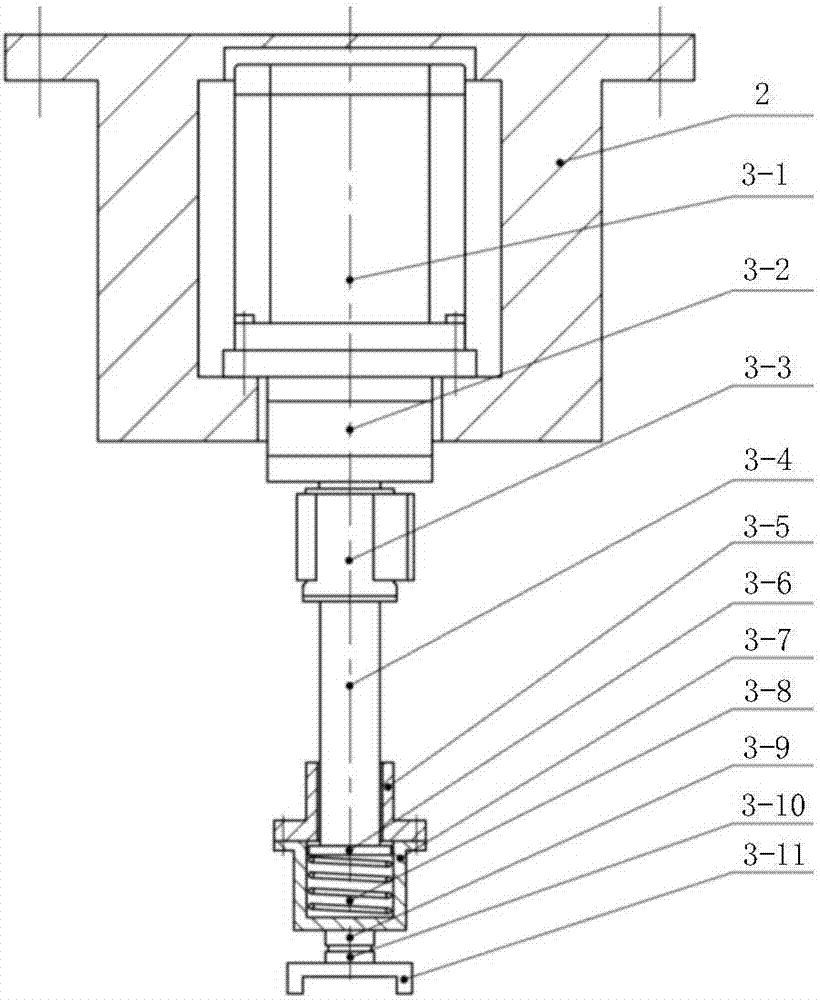

[0029] The technical solution adopted in the present invention is, a kind of preloaded bolt assembly equipment, such as figure 1 As shown, it includes press 1, mounting bracket 2, manipulator 3, and pressure bar 4; press 1, such as figure 2 As shown, it includes pressure cylinder 1-1, upper plate 1-2, moving middle plate 1-3, column 1-4 and base 1-5; manipulator 3, such as image 3 As shown, the manipulator 3 includes a motor 3-1, a reduction gear 3-2, a torque sensor 3-3, a ball spline rod 3-4 and a ball spline sleeve 3-5, a retaining ring 3-6, and a connecting sleeve 3-7 , compression spring 3-8, force sensor 3-9, adjustment pad 3-10 and wrench 3-11. The connection relationship of the preloading bolt assembly equipment is that the shell of the pressure cylinder 1-1 is fixedly connected with the upper plate, the piston rod of the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com