Rotor core

A rotor core and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, electromechanical devices, etc., can solve the problems of increasing the volume of the rotor plate, and achieve improved driving range, good mechanical strength, small mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

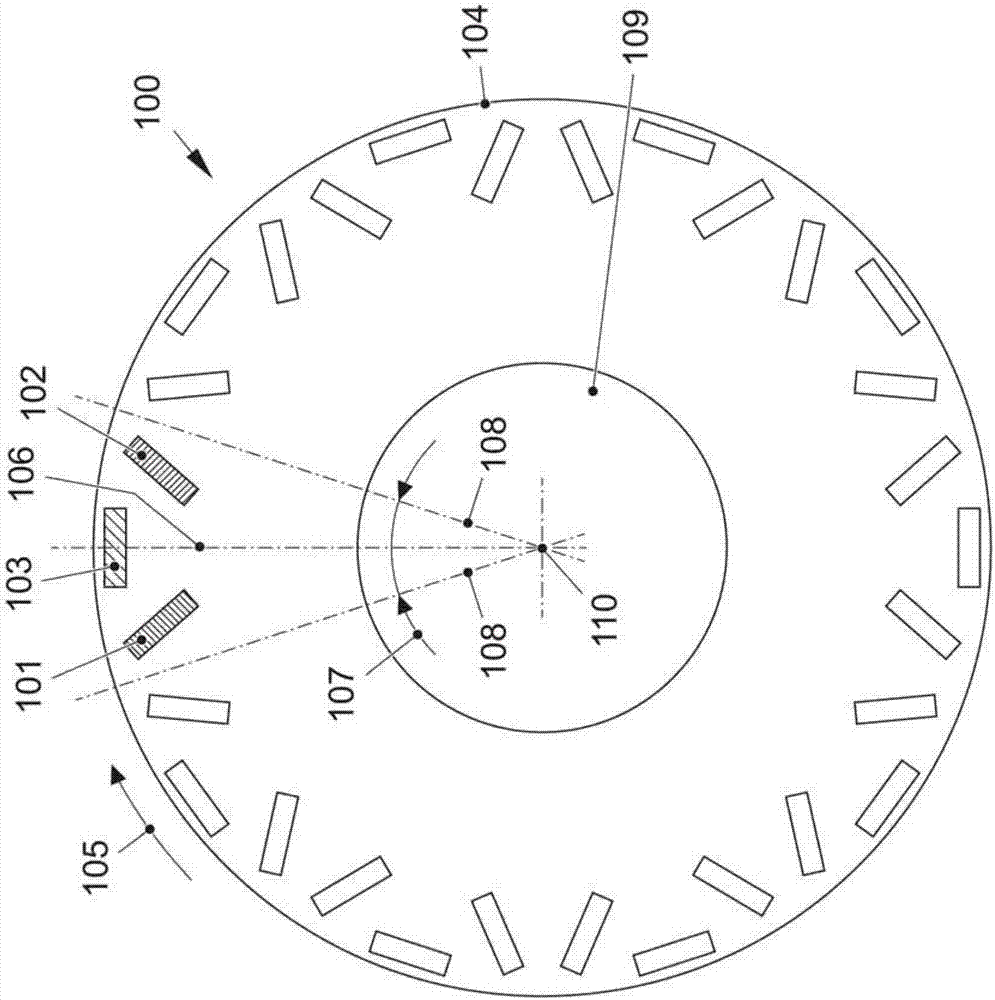

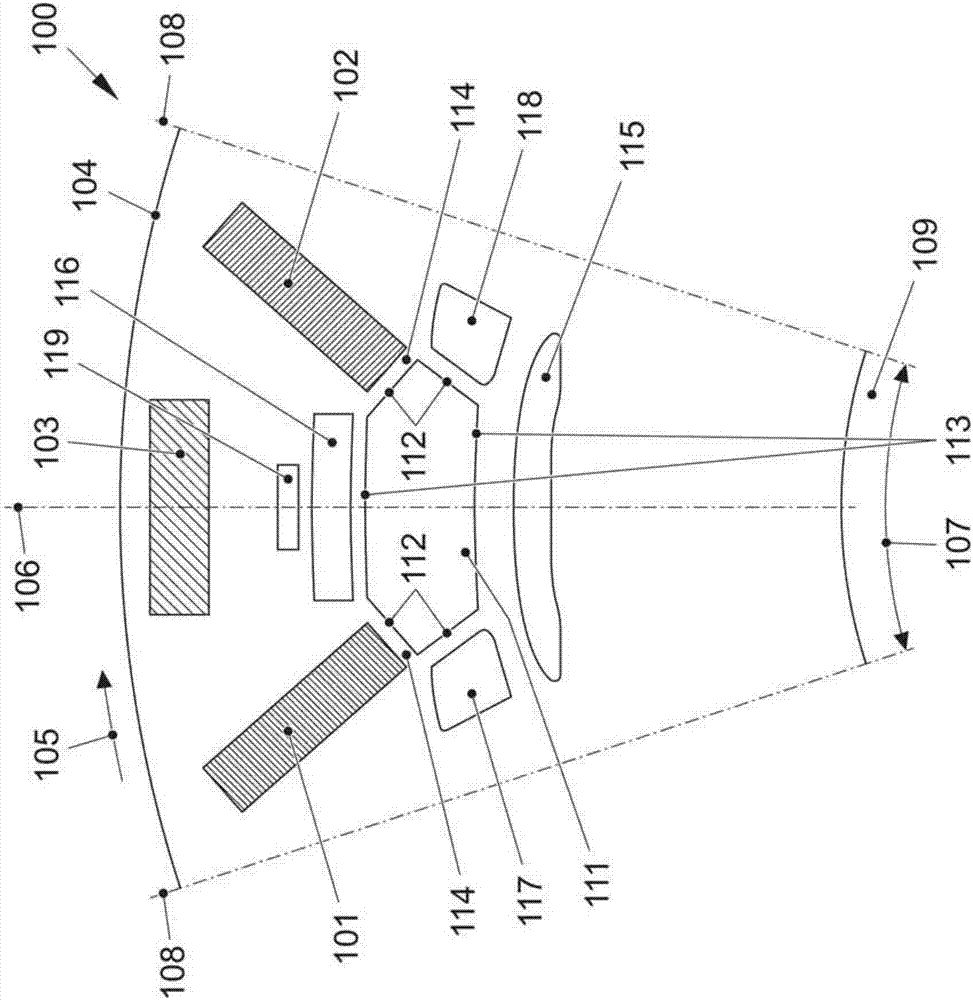

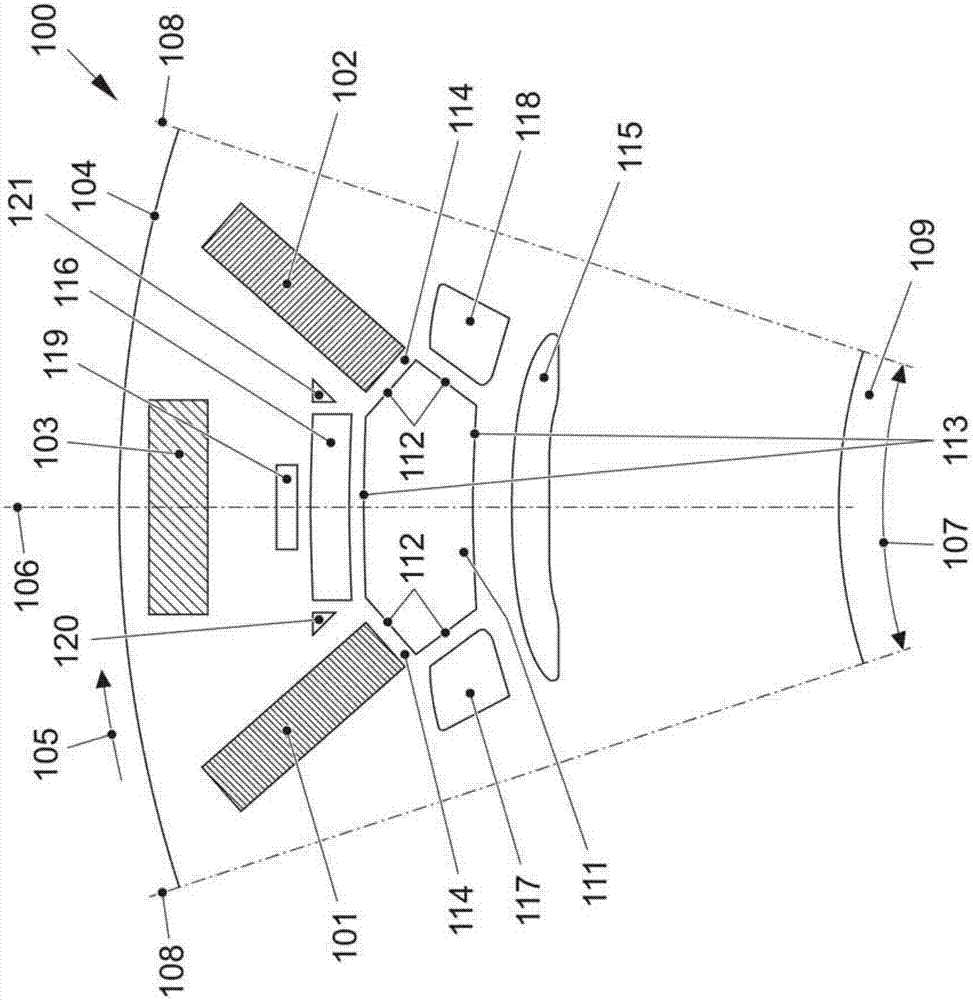

[0041] exist figure 1 Reference numeral 100 denotes a rotor core which serves as the basis for the embodiments of the invention explained below. The rotor core 100 is presented in an axial view, that is to say a view in the direction of the axis of rotation 110 of the rotor core 100 and thus in the direction of the rotor of the permanent magnet excited electric machine on which the rotor core is formed. The rotor core 100 here has, for example, ten magnetic poles. For each magnetic pole of the rotor core 100 or of the rotor formed of the rotor core, three permanent magnets 101, 102, 103 are provided, wherein two permanent magnets 101, 102 are arranged in a V-shaped configuration towards the rotor outer surface 104, ie Open radially outwards, and the third permanent magnet 103 is tangentially along the circumferential direction 105 and thus along the rotor outer surface 104 of the rotor core 100 at least almost centrally with respect to the radial center axis 106 of the V-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com