Horizontal dual-motor driving device for vision correction overlapped lens double-eye uniform sliding

A dual-motor drive, vision correction technology, applied in installation, glasses/goggles, optics, etc., can solve problems such as inability to realize transmission structure, cost increase, transmission structure error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

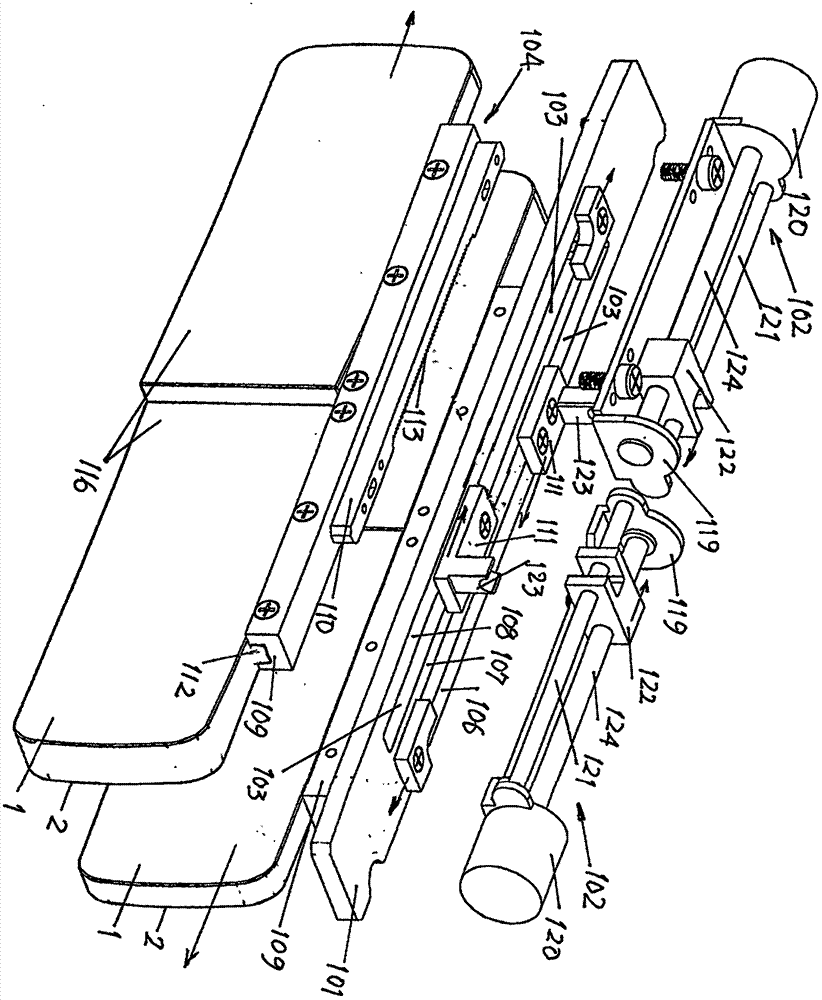

[0050] Embodiment 1. Horizontal dual-motor drive device with overlapping lenses for vision correction that slides uniformly for both eyes

[0051] Such as figure 1 , 2 , 3, 4, 5, 6, 7,

[0052] Horizontal dual-motor drive device with overlapping lenses for vision correction that slides both eyes uniformly, including a double-hole strip plate 101, two geared motor assemblies 102 respectively fixed on the two ends of the double-hole strip plate 101, and on the double-hole strip plate 101 The two strip-shaped holes 103 are respectively provided with two lens assemblies 104 which are slidably connected;

[0053] The structure of the double-hole strip plate 101: a strip plate is provided with two parallel strip holes 103, and the strip hole 103 divides the strip plate into an outer plate 106, a middle partition plate 107, and an inner plate 108;

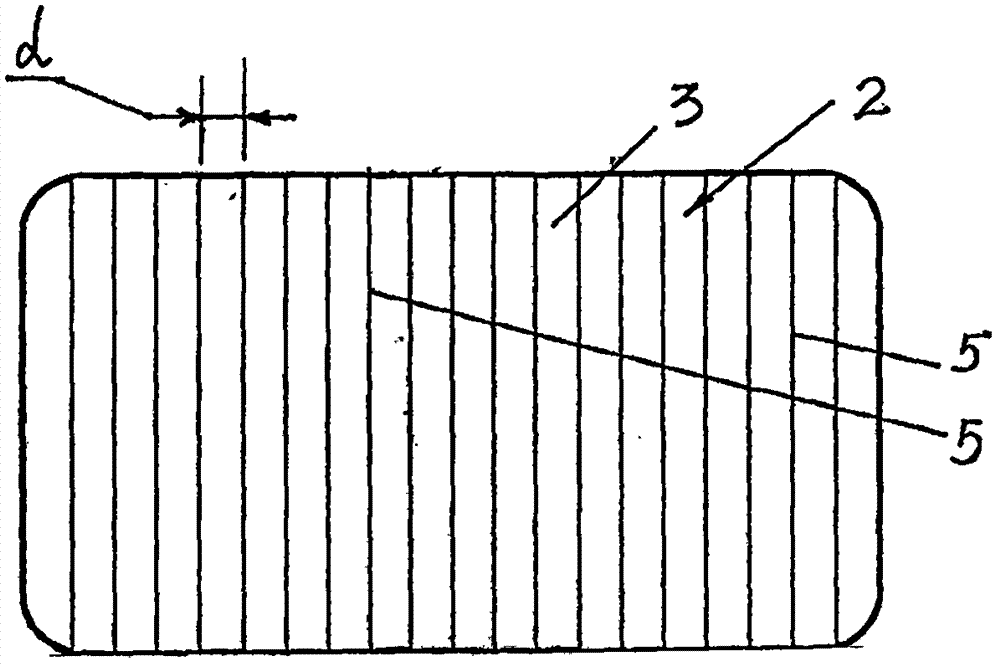

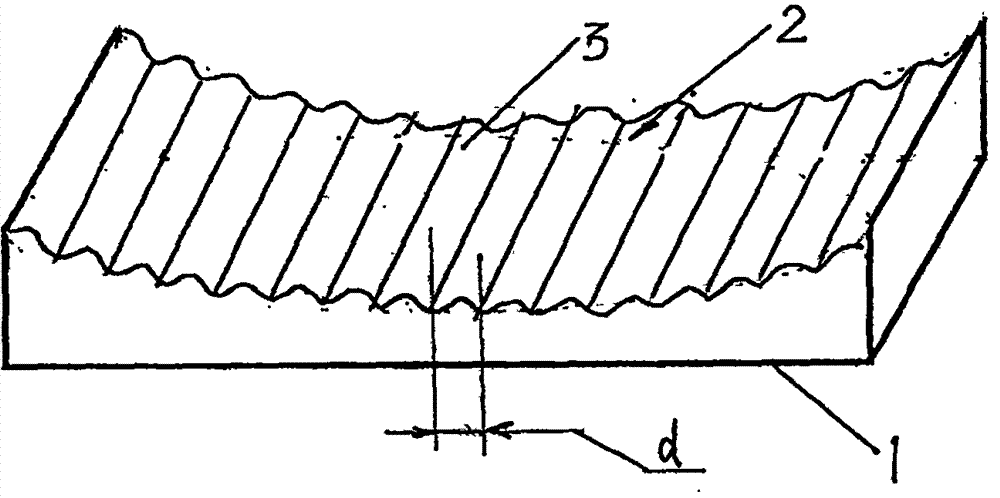

[0054]The structure of the lens assembly 104: a plurality of vertical equidistant zoom stripes 2, a grooved bar 109 connecting the le...

Embodiment 2

[0074] Embodiment 2. Horizontal dual-motor drive device with overlapping lenses for vision correction that slides both eyes uniformly

[0075] Such as figure 1 , 2 , 3, 4, 5, 6, 7,

[0076] As the main structure of embodiment 1, only the following content is different:

[0077] The structure of equidistant width strip curved surface 3 separating line 5 and double hole strip plate 101 of root vertical diopter striped lens 105 is as follows:

[0078] The included angle a between the equidistant width strip curved surfaces 3 of all multiple vertical equidistant zoom strip surfaces 2 of one lens assembly 104 and the separation line 5 and the double-hole strip plate 101 is 90 degrees.

[0079] The angle a between the equidistant width strip curved surfaces 3 of all the multiple vertical equidistant zoom strip surfaces 2 of the other lens assembly 104 and the double-hole strip plate 101 is 70 degrees.

[0080] All the plurality of vertical equidistant zoom stripe surfaces 2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com