Vertical single motor driving device for sliding overlapped double lens set for correcting vision

A single-motor-driven, vision-correction technology, applied in installation, glasses/goggles, optics, etc., can solve problems affecting treatment, unable to realize transmission structure, not provided, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

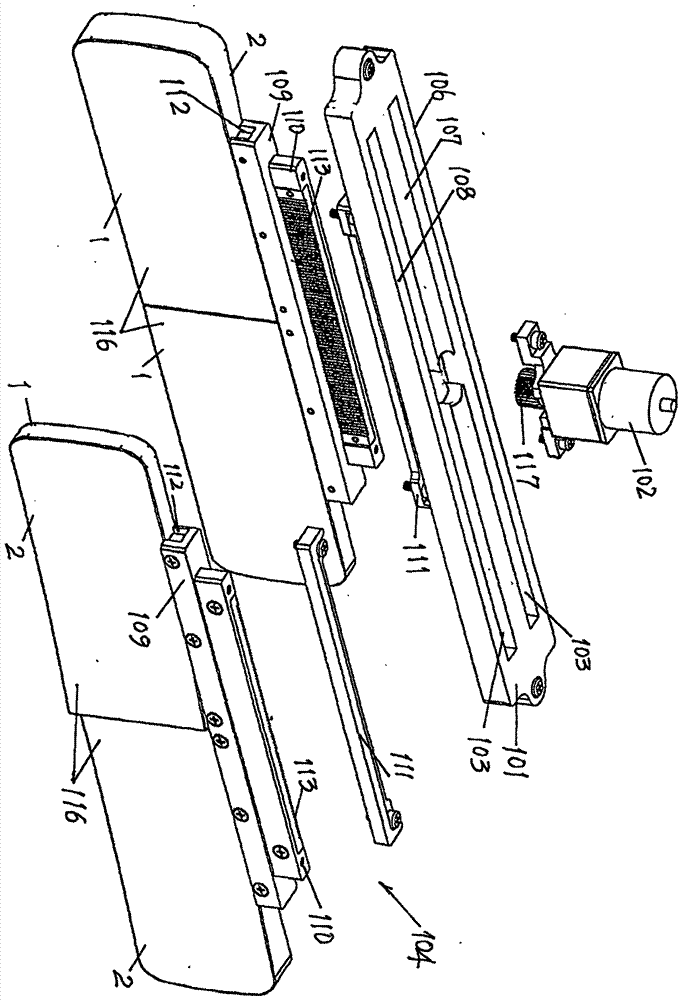

[0045] Embodiment 1. Vertical single-motor driving device for sliding of overlapping double lens groups for vision correction

[0046] Such as figure 1 , 2 , 3, 4, 5,

[0047] The vertical single-motor drive device for the sliding of the overlapping double lens group for vision correction includes a double-hole strip plate 101, a geared motor 102 fixed on the double-hole strip plate 101, and two of the double-hole strip plate 101 Two lens assemblies 104 that are slidingly connected are respectively provided in the strip holes 103;

[0048] The structure of the double-hole strip plate 101: a strip plate is provided with two parallel strip holes 103, the strip holes 103 divide the strip plate into an outer plate 106, a middle partition 107, and an inner plate 108; A center partition recess or a center partition hole 118 is provided on the upper center of the center partition 107;

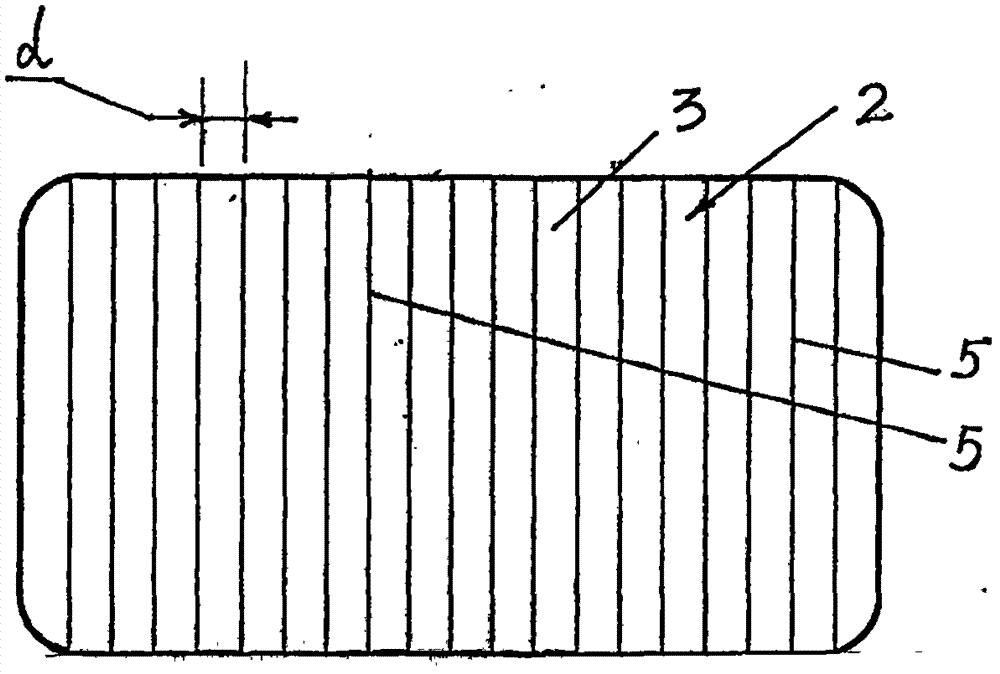

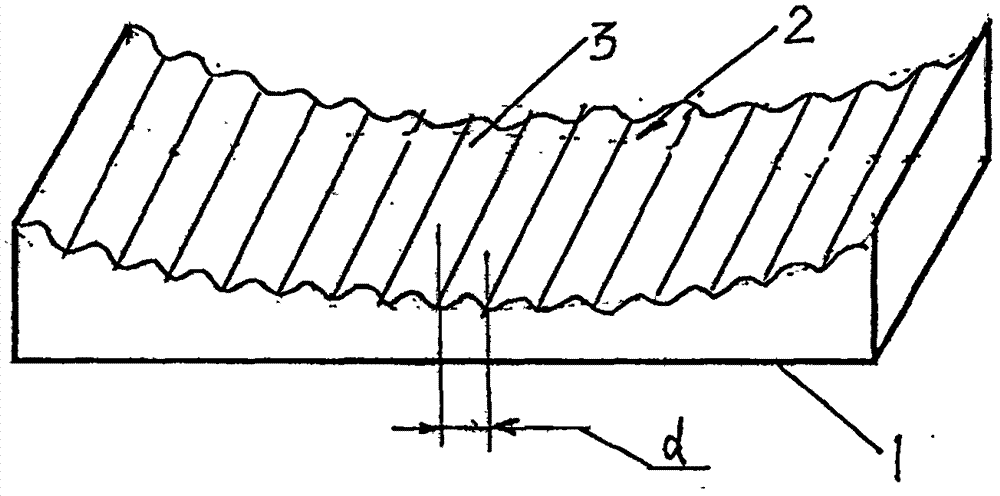

[0049] The structure of the lens assembly 104: there are a plurality of vertical equidistant zoom stripe ...

Embodiment 2

[0069] Embodiment 2. Vertical single-motor driving device for sliding of overlapping double lens groups for vision correction

[0070] Such as figure 1 , 2 , 3, 4, 5, according to the structure of the above embodiment 1, only all the equidistant width strip curved surfaces 3 of the lens are different,

[0071] The side-by-side arrangement structure of all the strip-shaped curved surfaces 3 of a plurality of vertical equidistant zoom stripe lens 2 with equal distances is as follows:

[0072] A plurality of vertical equidistant zoom stripe lens 2 has all the equal distance width strip curved surface 3 lens diopter value N the same, the specific arrangement distribution of the lens diopter value from 200 degrees to -800 is as follows:

[0073]

[0074] In the above table:

[0075] Ordinal numbers: 1 to 41 refer to the serial numbers of a total of 41 strip-shaped curved surfaces 3 with equal widths;

[0076] Power refers to: the lens refractive power of the equidistant width strip curved sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com