Steel structure factory building

A technology for steel structures and workshops, which is applied to building components, building structures, roof coverings, etc., and can solve problems such as easy falling to the ground and unstable steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

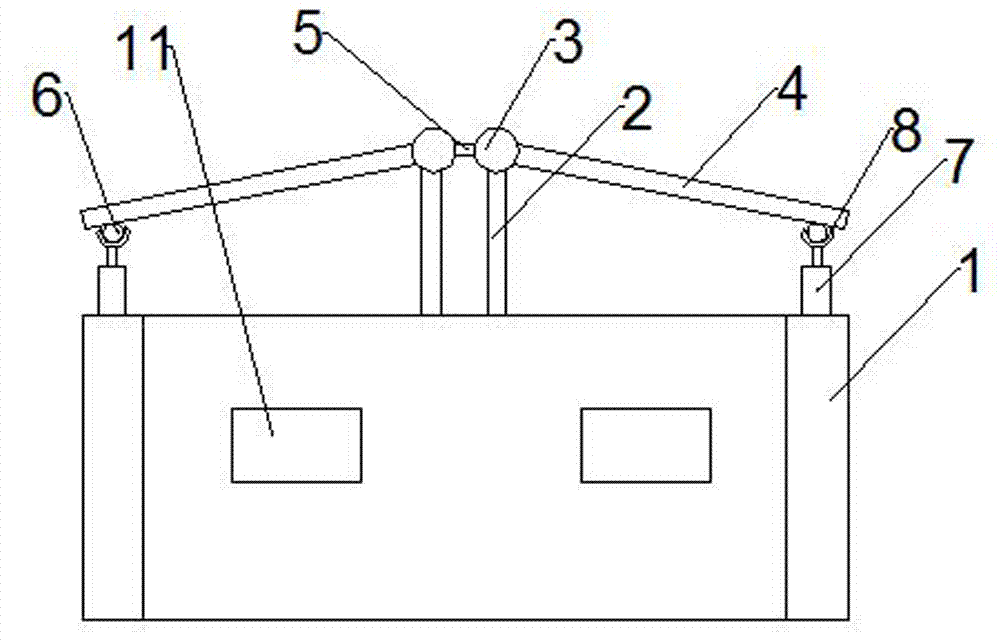

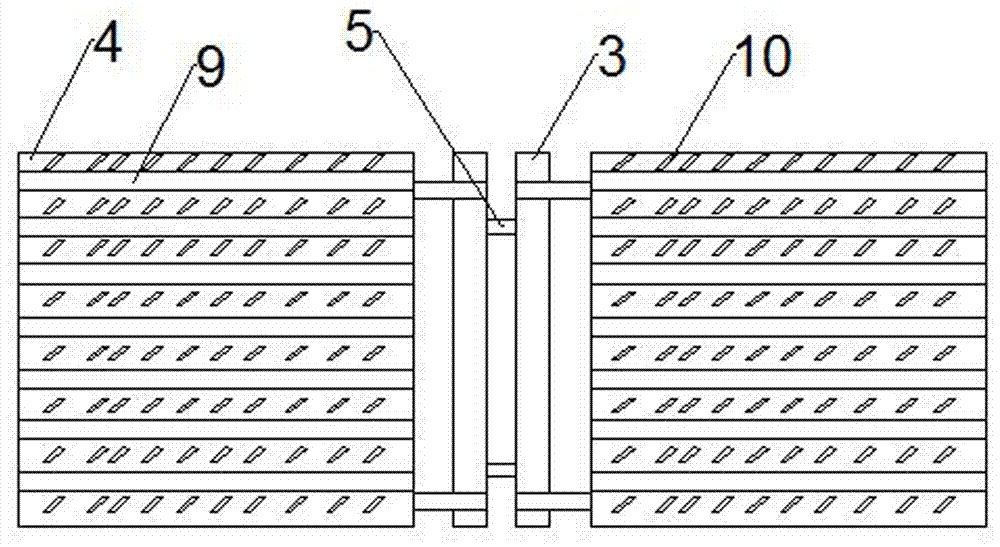

[0018] The reference signs in the drawings of the specification include: column 1, support column 2, pin shaft 3, cover plate 4, connecting shaft 5, ball 6, cylinder 7, groove 8, groove 9, anti-skid stripe 10, glass window 11 .

[0019] The embodiment is basically as attached figure 1 And attached figure 2 Shown: a factory building with steel structure, including a roof and a rectangular room body, the four corners of the room body are vertically provided with columns 1, and the middle of the adjacent column 1 is vertically provided with supporting columns 2, and the roof includes Two pin shafts 3, both pin shafts 3 are rotatably connected with a cover plate 4, the cover plate 4 is arranged obliquely, a connecting shaft 5 is arranged between the two pin shafts 3, and the two pin shafts 3 are located on opposite support columns 2 and is fixedly connected with the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com