Thermo-sensitive and controllable-release lubricant used for well drilling fluid and preparation method for lubricant

A temperature-sensitive drilling fluid technology, applied in the field of drilling fluid lubricants, can solve the problems of high drilling fluid cost, short action time, complex lubricant production process, etc., and achieve the effect of easy promotion and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 15g of 7# white oil into the reaction vessel, heat to 60°C; slowly add 10g of oleic acid amide during stirring, after the dissolution is complete, add 3g of monopalmitic acid polyoxyethylene sorbitan, add 2g of 601# Nano-calcium carbonate (produced by Fujian Hongfeng Nano Technology Co., Ltd.), stir again, and add in about 50 minutes; slowly add 40.5g of water to the above reactor, stirring at a speed of 500 r / min, after the addition is completed, add 3g of polyoxyethylene-polyoxypropylene-polyoxyethylene (PEO-PPO-PEO) block copolymer, maintain the temperature at 60°C during the process, continue to stir for 30min; reduce the temperature of the reactor to 30°C, add 1g of dehydrated sorrel Alcohol monopalmitate, add 25.4g of water, increase the stirring speed to 5000 r / min, add 0.1g of antifoaming agent simethicone to defoam, continue stirring for 30min, cool to room temperature, and discharge to obtain drilling fluid Controlled-release lubricants with temperature se...

Embodiment 2

[0025] Add 20g of 15# white oil into the reaction vessel, heat to 70°C; slowly add 15g of oleic acid amide during stirring, after the dissolution is complete, add 4.5g of polyoxyethylene sorbitan monostearate, add 4g 602# nano-calcium carbonate, stir evenly again, and finish adding in about 50 minutes; slowly add 28.5g of water to the above reactor at a stirring speed of 500R / min, after the addition is completed, add 4.5g of PEO-PPO-PEO embedded Segment copolymer, keep the temperature at 70°C during the process, continue to stir for 30min; reduce the temperature of the reactor to 40°C, add 2g of sorbitan monostearate, add 21.2g of water, and increase the stirring speed to 5000 r / min During the process, add 0.3g of antifoaming agent simethicone to defoam, continue to stir for 30 minutes, cool to room temperature, and discharge to obtain a temperature-sensitive controllable release lubricant for drilling fluid.

Embodiment 3

[0027] Add 25g of 24# white oil into the reaction vessel, heat to 70°C; slowly add 20g of oleic acid amide during stirring, after the dissolution is complete, add 6g of monooleic acid polyoxyethylene sorbitan, add 5g of 603# Nano-calcium carbonate, stirred evenly again, and finished adding in about 50 minutes; slowly added 20g of water to the above reactor at a stirring speed of 500 r / min, after the addition was completed, added 6g of PEO-PPO-PEO block copolymer L94, maintain the temperature at 70°C during the process, and continue to stir for 30 minutes; reduce the temperature of the reactor to 50°C, add 3g of sorbitan monooleate, add 14.5g of water, increase the stirring speed to 5000 r / min, and add 0.5g of antifoaming agent simethicone to defoam, continue to stir for 30 minutes, cool to room temperature, and discharge to obtain a temperature-sensitive controllable release lubricant for drilling fluid.

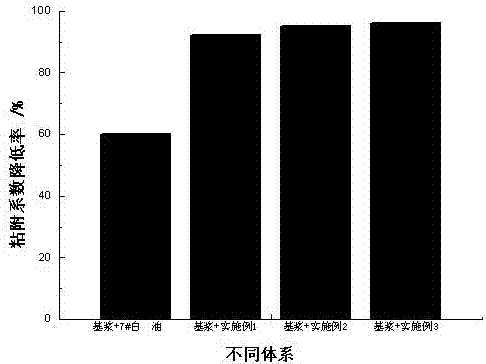

[0028] The following test was further carried out to test the lubricati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com