A kind of biodegradable polyester composition

A biodegradable polyester and biodegradable technology, applied in the field of biodegradable polyester compositions, can solve the problems of harm to the human body, damage to polyester performance, and lower viscosity of polyester mixtures, so as to reduce friction, facilitate opening, and improve static friction The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

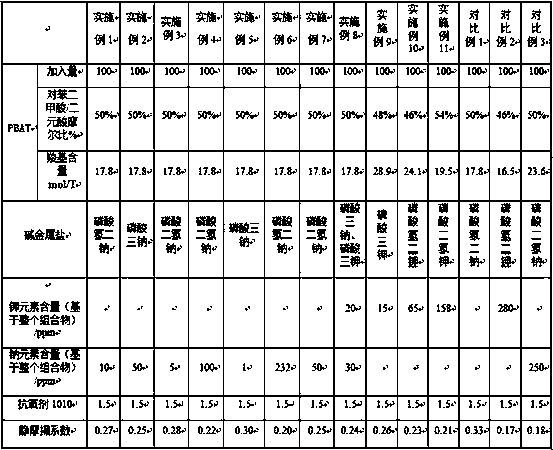

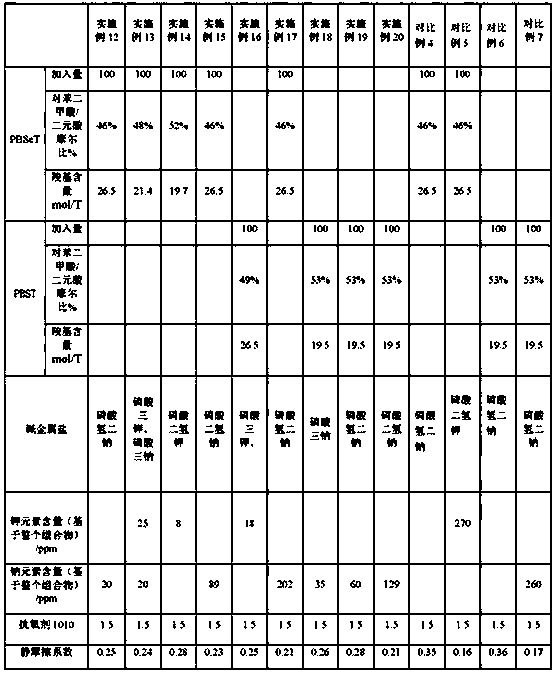

Embodiment 1-20 and comparative example 1-7

[0036] According to the formula shown in Table 1, mix biodegradable polyester, alkali metal salt, and antioxidant 1010, put them into a single-screw extruder, extrude and pelletize at 140°C-232°C, and obtain biodegradable polyester ester composition. The performance test data are shown in Table 1.

[0037] Wherein, the weight content of potassium element and sodium element in the biodegradable polyester composition is adjusted and measured by the actual amount of alkali metal salt added during the preparation process of the biodegradable polyester composition.

[0038] Performance evaluation method:

[0039] Quantitative method for alkali metal elements:

[0040] Weigh 0.500g of the biodegradable polyester composition sample to be tested, add 10ml of concentrated sulfuric acid, heat and digest on the electric heating plate, add hydrogen peroxide dropwise until the digestion is complete, and set the solution to 50ml. Use dilute sulfuric acid solution of the element to be tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com