An automatic leveling system and leveling method for substrates of laser selective melting forming equipment

A laser selective melting and automatic leveling technology, applied in the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problems of inability to guarantee product quality, affect the efficiency of 3D printing, cumbersome operation, etc., and achieve high industrial production value , improve efficiency and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

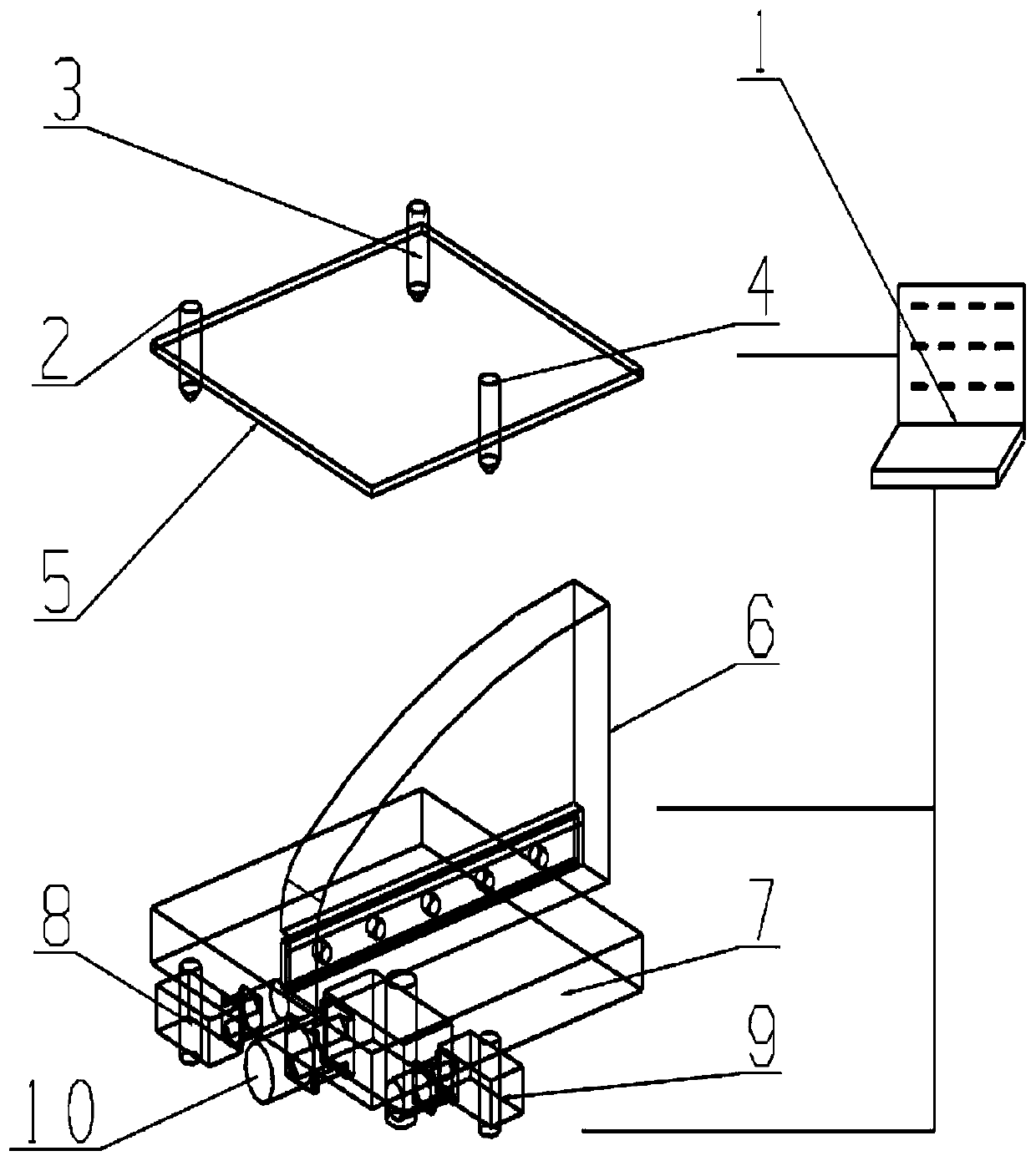

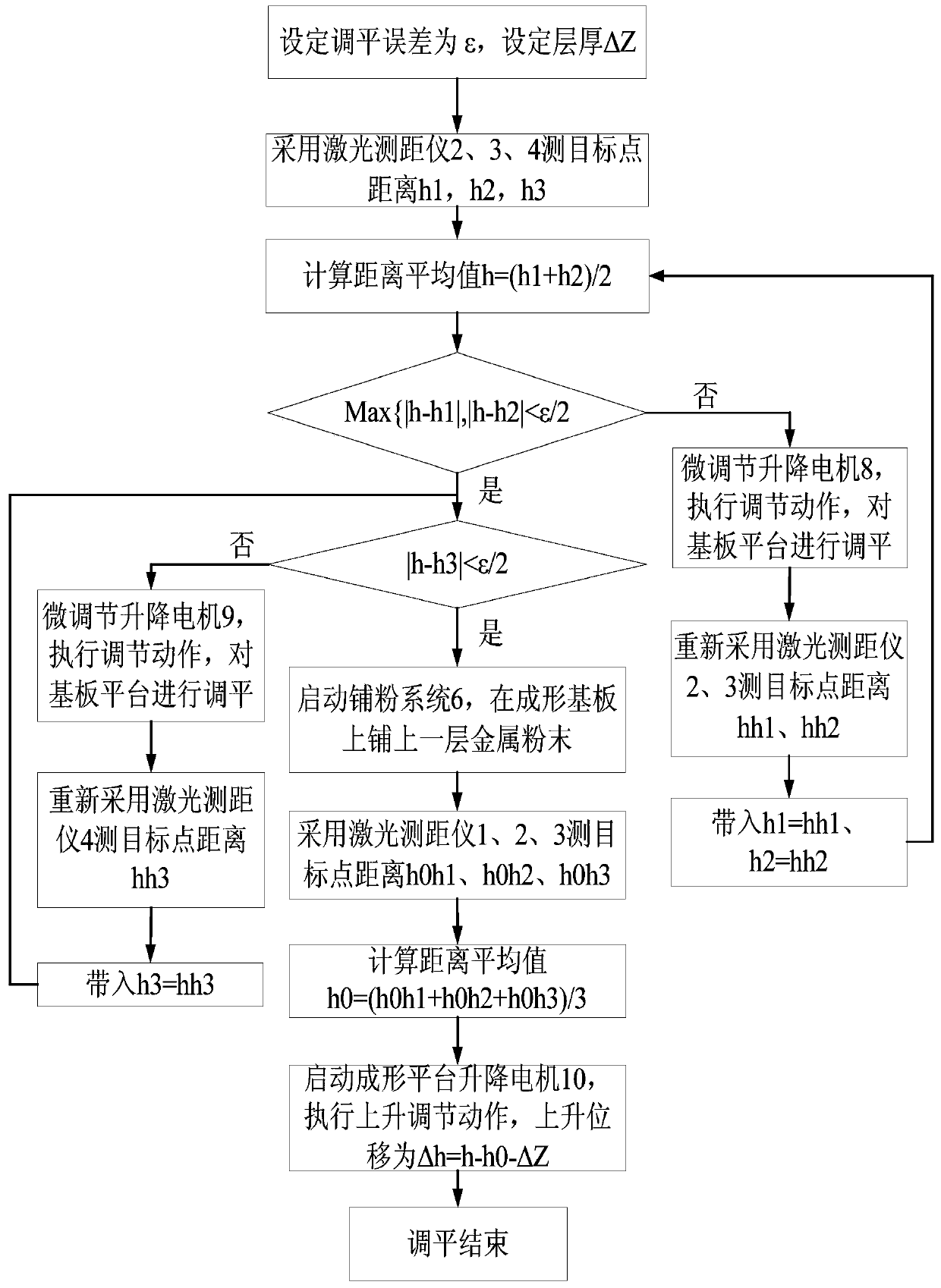

[0029] Such as figure 1 As shown, an automatic leveling system for the forming platform of laser selective melting and forming equipment, including a computer control system 1, a first laser range finder 2, a second laser range finder 3, a third laser range finder 4, and above the forming cabin Fixed plate 5, forming platform 7, the first micro-adjustment lifting motor 8 for adjusting the forming platform 7, the second micro-adjusting lifting motor 9, the lifting motor 10 for controlling the movement of the forming platform 7 and the scraper powder spreading system 6, so The first laser range finder 2, the second laser range finder 3, and the third laser range finder 4 are located on the fixed plate 5 above the forming cabin and are distributed in three different positions, wherein the first laser range finder 2, The second laser range finder 3 is located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com