A special hoop bending machine for making high-speed rail box girder steel bars

A hoop bending machine and box girder technology, applied in the field of steel bar hoop bending machines, can solve the problems of low work efficiency, large shape error and high labor intensity, and achieve the effects of simple structure, good hoop quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the drawings:

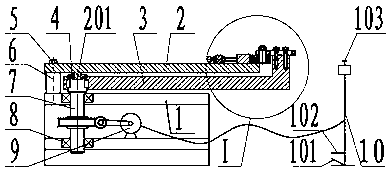

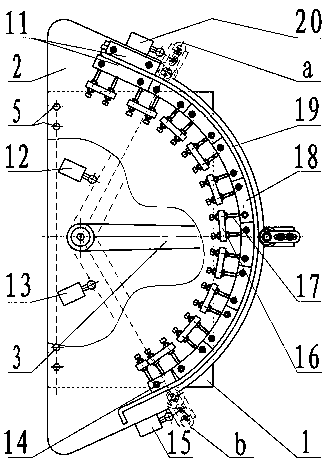

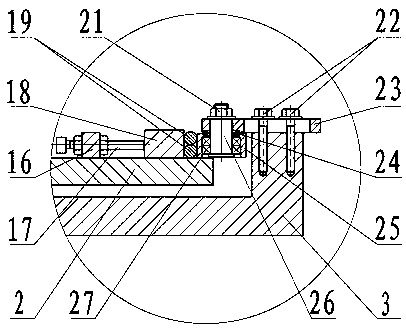

[0021] As attached figure 1 , 2 , 3, the workbench 2 is fastened to the frame 1 by a number of bolts 5 and gaskets 6; the straight section mold 11 and the arc mold 18 are fastened to the workbench 2 by bolts, the straight section mold 11 and the arc The shape mold 18 together constitutes a combined bending mold inside the steel hoop on the worktable 2, and the straight section mold 11 is placed at the front end of the arc mold 18; the vertical shaft 7 is vertically supported in the frame 1 through two bearings 8 and passes through the first The ends of the three bearings 4 are positioned on the positioning journal 201 on the bottom surface of the table 2; one end of the rotating arm 3 is fixedly connected to the vertical shaft 7, which lies horizontally between the table 2 and the frame 1, and makes the other One end protrudes out of the worktable 2, and at the protruding end is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com