Small double-sided compressor for children's wear

A lining machine and small technology, applied in the field of garment machinery, can solve the problems of unaffordable presses, limited purchasing power and high price of small garment processing factories, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

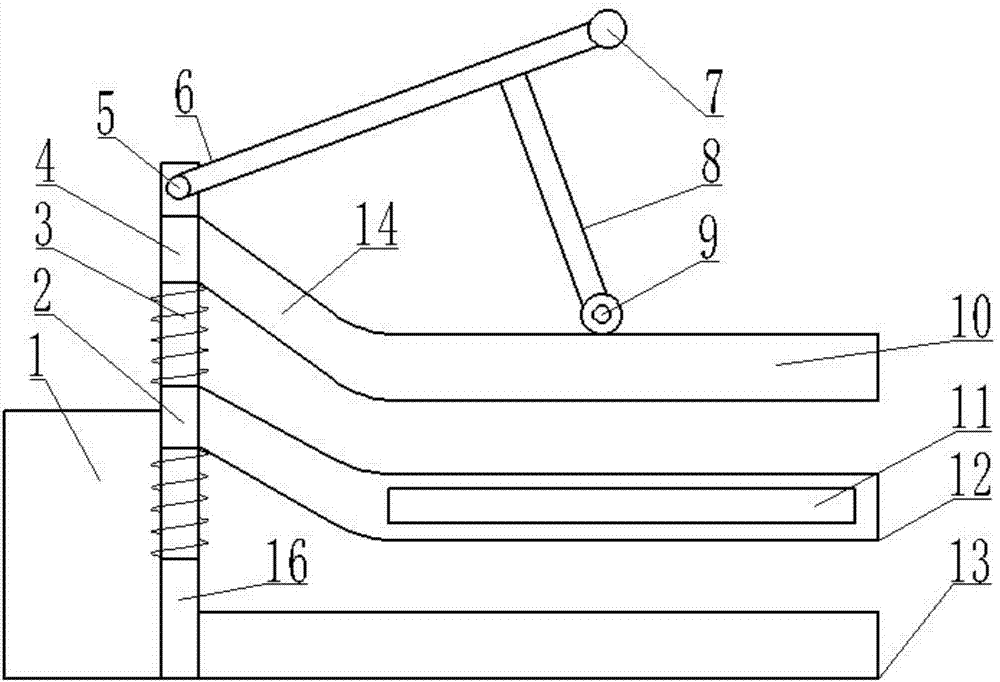

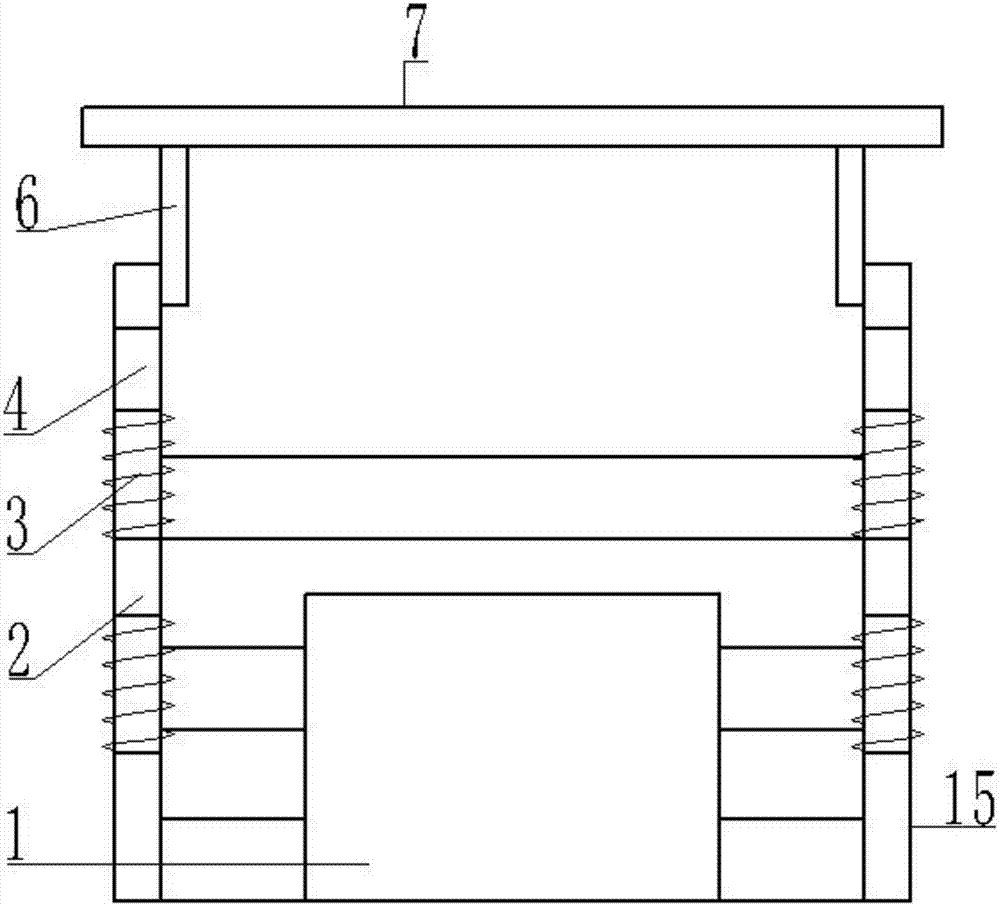

[0021] see Figure 1-2 , this embodiment provides a small double-sided lining machine for children's clothing, including a heating source 1, a support rod 15, a first pressing plate 10, a heating plate 12, and a second pressing plate 13; the heating source 1 is connected to an external power supply; The support rod 15 is provided with the first snap ring 2, the spring 3, the second snap ring 4, the third snap ring 16 and the rotating shaft 5, the support rod 15 is provided with two, and the diameters of the upper and lower ends of the support rod 15 are larger than the second snap ring. The inner diameter of the ring 4 and the third snap ring 16, the first snap ring 2, the second snap ring 4 and the third snap ring 16 are movably connected on the support rod 15 under the joint action of the spring 3; the third snap ring 16 is arranged at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com