3D printer

A technology of 3D printers and printing tables, applied in the field of 3D printing, can solve the problems of difficult control of the use of printing materials, complex structure of the 3D space positioning system, and difficult promotion and use, etc., and achieve the effect of convenient control, simple structure, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

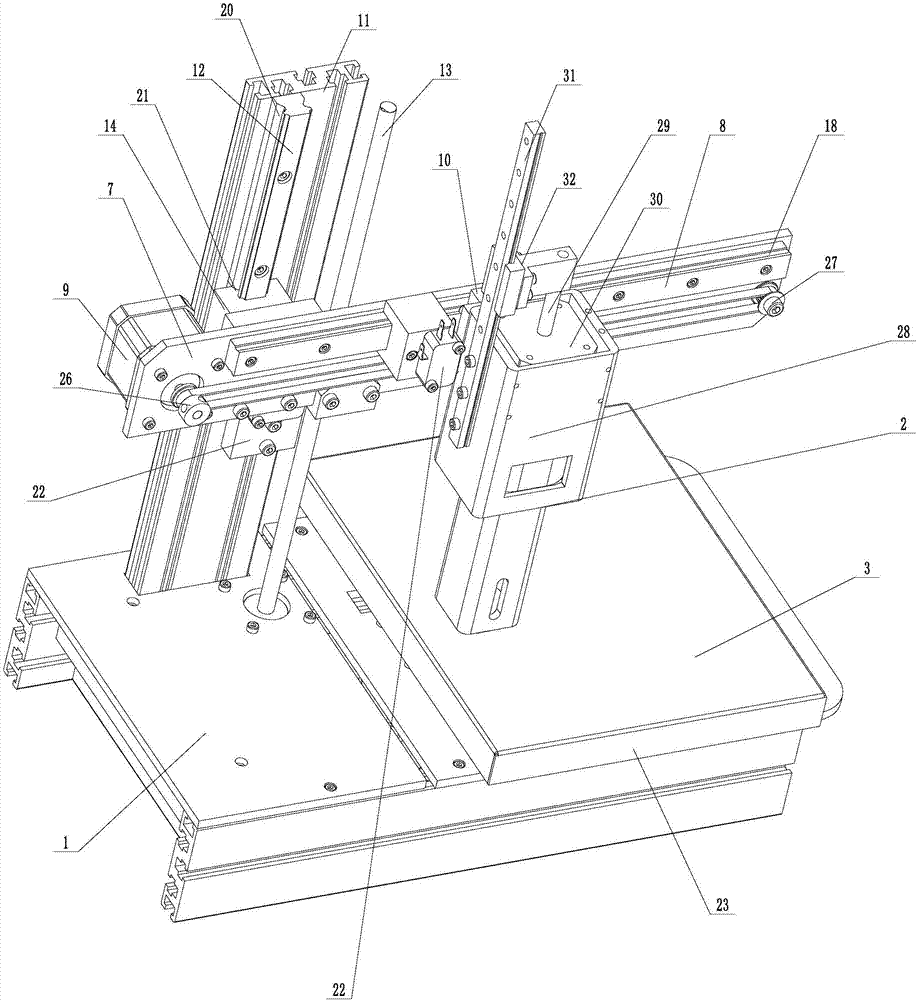

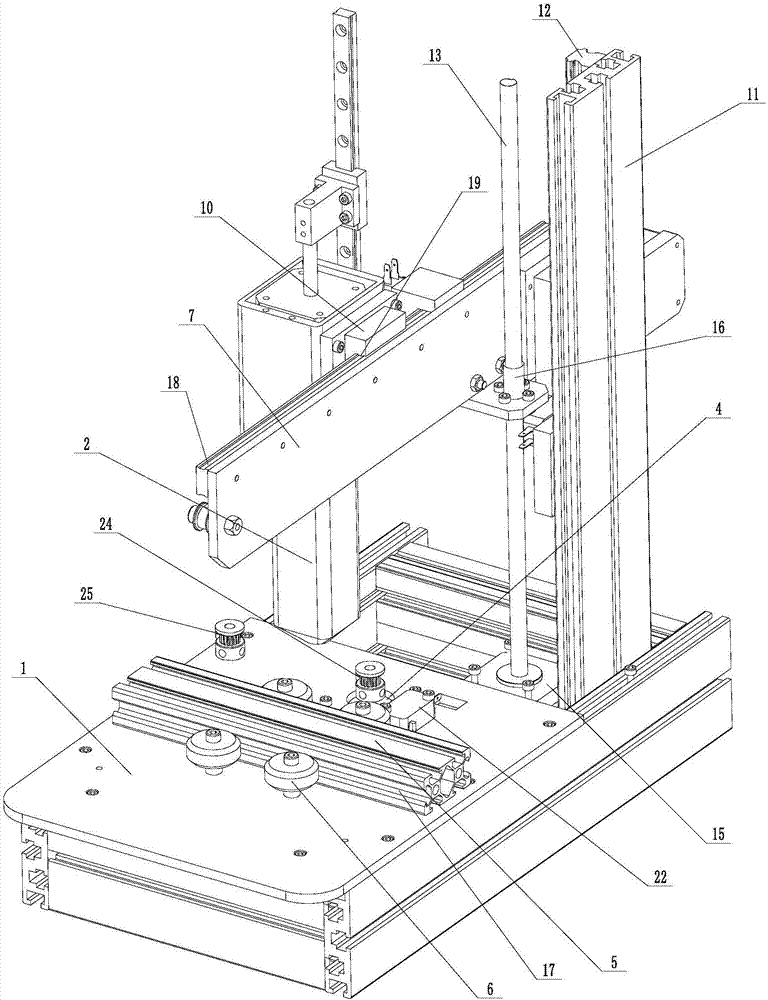

[0024] Embodiment 1: a kind of 3D printer (see attached figure 1 , attached figure 2), including a main machine 1, a nozzle 2, an X-axis assembly, a Y-axis assembly, and a Z-axis assembly. The X-axis assembly includes a printing table 3 and an X-axis motor 4. The lower surface of the printing table is provided with a slide rail 5 supported on the main machine. Two guide wheels 6 are installed on both sides of the slide rail on the main machine, an X-axis timing belt driven by an X-axis motor is installed on the main machine, and an X-axis slider is arranged on the lower surface of the printing table, and the X-axis slider is synchronized with the X-axis Belt connection; both sides of the slide rail are provided with guide grooves 17, the guide wheels are attached to the bottom surface of the guide grooves, and the upper and lower ends of the guide wheels are all provided with chamfers. The X-axis motor output shaft is connected with the X-axis driving pulley 24, the X-axis d...

Embodiment 2

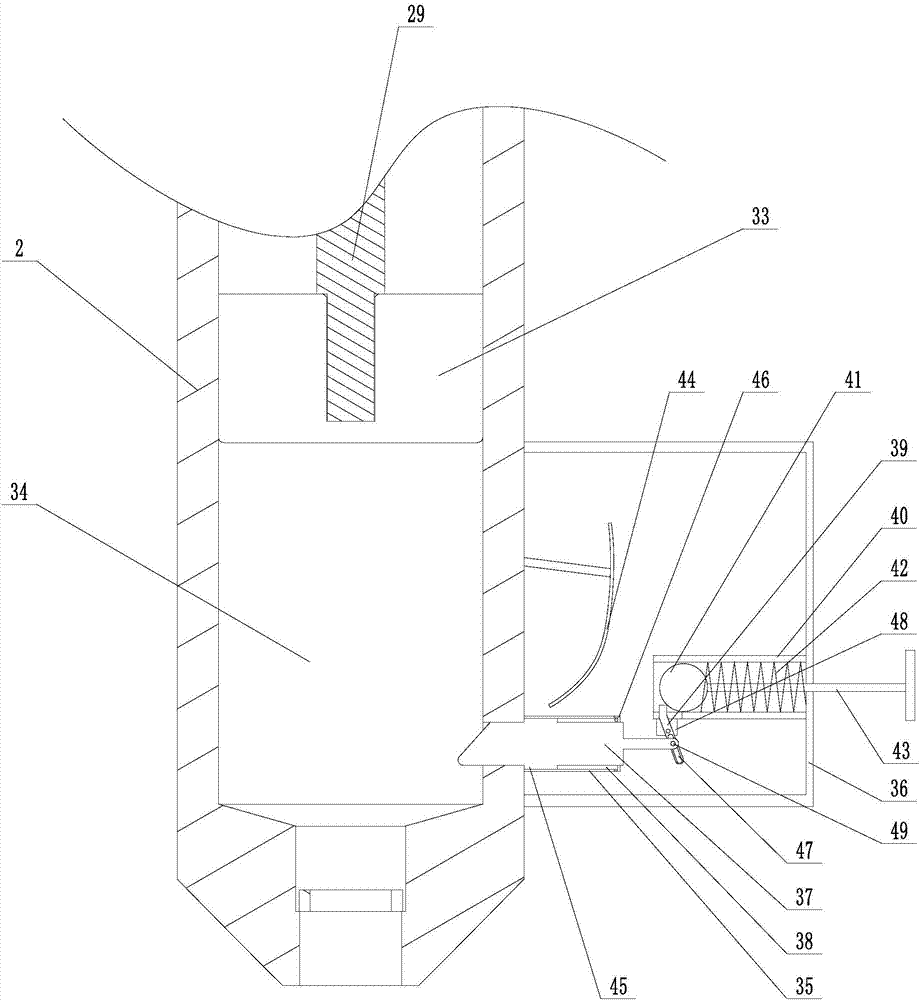

[0026] Embodiment 2: a kind of 3D printer (see attached Figures 1 to 3 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, the lower end of the nozzle is provided with a material chamber 34, the material chamber is provided with a piston rod for pushing and extruding materials, and the outer wall of the nozzle is connected with a positioning sleeve near the lower end 35. Mounting box 36, telescopic column 37 is installed in the positioning sleeve, the front end of the telescopic column extends out of the material cavity inner wall, positioning spring 38 is installed in the positioning sleeve, the front end of the telescopic column is a wedge-shaped structure, and the rear end of the telescopic column is movably connected with the push rod 39, and the installation The box inner wall is connected with a guide sleeve 40, and the push rod is hinged at the front end of the guide sleeve. A bumper ball 41 and a compression spring 42 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com