Capacitor monitoring system

A monitoring system and capacitor technology, applied in the field of capacitors, can solve problems such as fire or explosion, prolonging power failure time, and failure to locate capacitors quickly and in time, achieving precise positioning and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

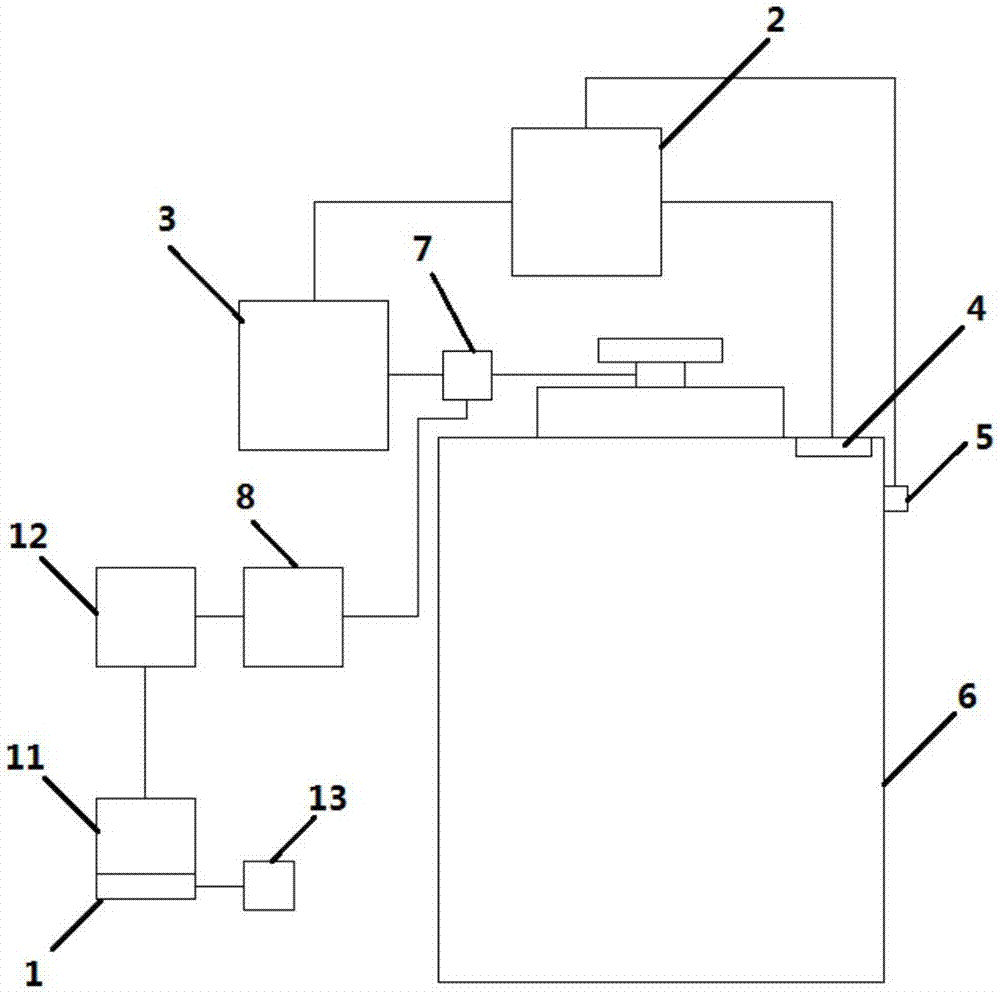

[0017] A capacitor monitoring system such as figure 1 As shown, it includes a monitoring center 1, a controller 2, a circuit breaker 3, a pressure sensor 4, a buzzer 5, and a capacitor 6. The monitoring center 1 includes a computer 11 and a data receiver 12. The pressure sensor 4 is arranged on the capacitor 6, the pressure sensor 4 is connected to the controller 2, the controller 2 is connected to the circuit breaker 3 and the buzzer 5 respectively, the circuit breaker 3 is connected to the main circuit after being connected in series with the capacitor 6, and the circuit breaker 3 and the capacitor A current sensor 7 is connected in series on the circuit between 6, and the current sensor 7 is connected with the signal collector 8, and the signal collector 8 is connected with the data receiver 12 of the monitoring center 1 through data transmission, and the data receiver 12 is connected with the computer 11 phase connections.

[0018] Further, the data transmission method be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com