An energy-saving transformer cooler control cabinet and its control method

A control method and cooler technology, applied in sequence/logic controller program control, electrical program control, etc., can solve the problems of poor energy saving effect, insignificant effect, poor flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

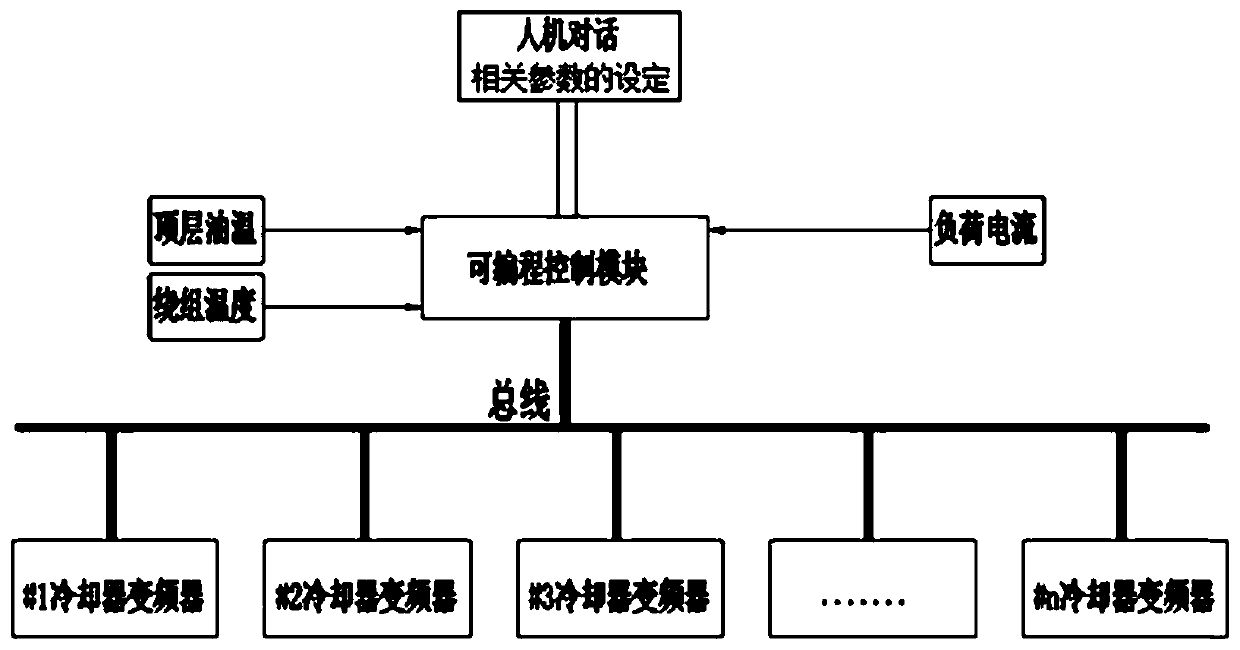

[0046] The invention provides an energy-saving transformer cooler control method. The control logic and the frequency conversion adjustment method cooperate to complete the energy-saving control of the transformer cooler.

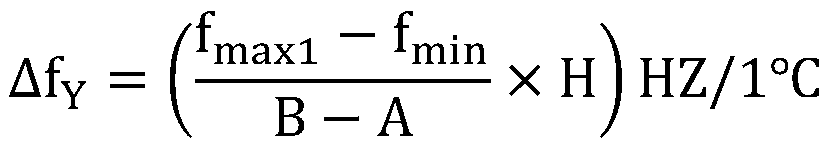

[0047] An energy-saving transformer cooler control cabinet control method completely breaks the traditional cooler into three modes of "working group", "auxiliary group" and "standby group", but according to the top oil temperature of the transformer, winding The relevant parameters of temperature, load current and transformers and coolers are automatically calculated by the programmable logic control module at a certain time interval to calculate the number of coolers that should be put into operation at the moment, and compared with the current coolers that have been put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com