Quartz tube device for detection of vacuum glass vacuum degree and detection method thereof

A technology of vacuum glass and quartz tube, which is applied in the direction of vacuum gauges that measure medium pressure by measuring the change of medium thermal conductivity, etc., which can solve the problems of long time, high cost, difficult operation, etc., and save time and energy The effect of energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

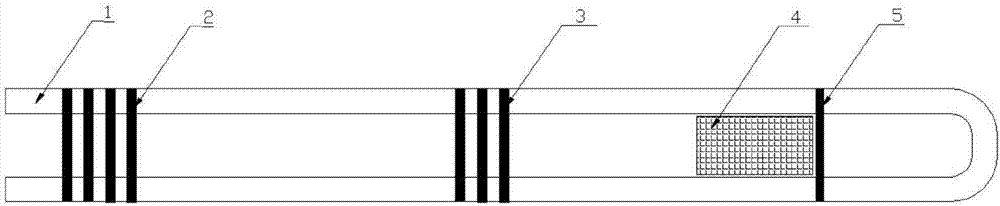

[0021] Such as figure 1 As shown, a quartz tube device for detecting the vacuum degree of vacuum glass includes a cylindrical quartz tube 1 with an open end. The outer diameter of the quartz tube 1 is 3 mm, the inner diameter is 1.82 mm, and the length is 70 mm. There is a steel wire 4 that can move freely. The steel wire 4 is 5 mm long and 1.80 mm in diameter. There are scale lines marking the vacuum degree value sintered at high temperature on the outer surface of the quartz tube 1. The scale lines are divided into three groups. The first group of scale lines 5 One is set at 5.4mm from the bottom of the tube; the second group of scale lines 3 has three lines, which are set at intervals of 1mm between 28.6 and 31.6mm from the bottom of the tube; the third set of scale lines 2 has four lines, which are set at intervals of 1mm Between 56.0 and 60.0mm from the bottom of the tube.

[0022] A method for detecting the vacuum degree of vacuum glass by utilizing a quartz tube device...

Embodiment 2

[0027] Such as figure 1 As shown, a quartz tube device for detecting the vacuum degree of vacuum glass includes a cylindrical quartz tube 1 with an open end. The outer diameter of the quartz tube 1 is 3 mm, the inner diameter is 1.83 mm, and the length is 75 mm. There is a steel wire 4 that can move freely. The steel wire 4 is 5 mm long and 1.81 mm in diameter. There are scale lines marking the vacuum degree value sintered at high temperature on the outer surface of the quartz tube 1. The scale lines are divided into three groups. The first group of scale lines 5 There is one line, which is set at 5.4mm from the bottom of the tube; the second group of scale lines 3 has three lines, which are set at intervals of 1 mm between 29.5 and 32.5 mm from the bottom of the tube; the third set of line 2 has four lines, which are set at intervals of 1 mm Between 59.5 and 63.5mm from the bottom of the tube.

[0028] A method for detecting the vacuum degree of vacuum glass by utilizing a q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com