Planet-row equal-ratio-gear multiplicative transmission

A planetary row and transmission technology, applied in the field of mechanical transmissions, can solve the problems of large transmissions, equal proportions, and difficulty in multiple gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

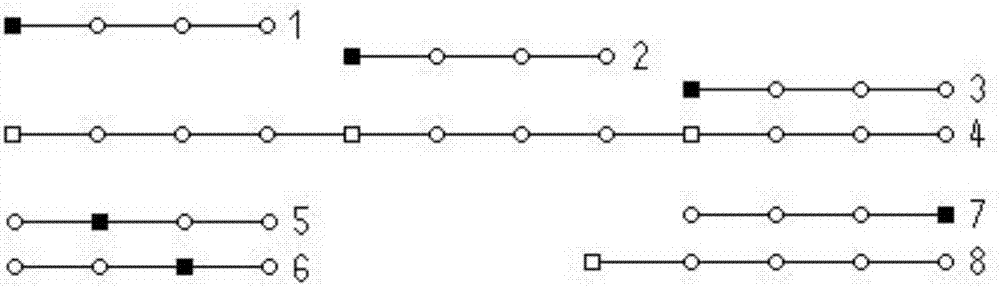

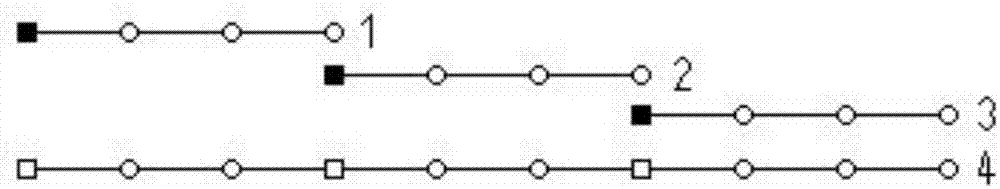

[0029] Embodiment 1: The three-row planetary row proportional gear multiplication of the present invention is applied. No. 1 single-layer planetary row 1 is the first proportional transmission, No. 2 single-layer planetary row 2 is the second proportional transmission, and No. 3 single-layer planetary row 3 is the third proportional transmission And with reverse gear. The constant ratio planetary transmissions are connected in series, see for each connection Figure 5 . In Embodiment 1, the characteristic parameters of each planetary row take values of a1=1.84, a2=1.46, and a3=5.26316. That is, the No. 1 planetary row sun gear has 100 teeth, the planetary gear has 42 teeth, and the inner ring gear has 184 teeth. The number of gears participating in the multiplication of planetary row equal ratio gears is 3, and the first sub-transmission equal ratio is 2.84. The number of sun gear teeth on the second planetary row is 100, the number of planetary gear teeth is 23, and the ...

Embodiment 2

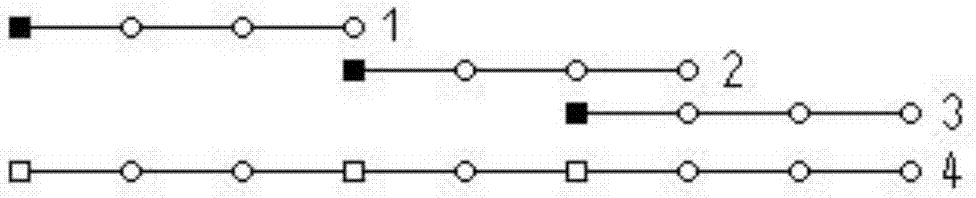

[0036] Embodiment 2: A four-row planetary-row equal-ratio positive eighteen-speed transmission with reverse gear applied to the multiplication of planetary-row equal-ratio gears according to the present invention. No. 1 double-layer planetary row 1 is the first proportional transmission, No. 2 single-layer planetary row 2 is the second proportional transmission, No. 3 single-layer planetary row 3 and No. 4 single-layer planetary row 4 form the third proportional transmission with reverse gear. The proportional sub-variators are connected in series, see for each connection Figure 6 . In Embodiment 2, the characteristic parameters of each planetary row take values of a1=6.405405, a2=1.7692308, a3=1.506024096, a4=3.0. That is, the No. 1 planetary row sun gear has 37 teeth, the double-layer planetary gear has 50 teeth, and the inner ring gear has 237 teeth. The number of gears participating in the multiplication of planetary row equal ratio gears is 3, and the first sub-trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com