Pneumatic type/mechanical type combined adjustment mach number 0-7 stage combined engine air inlet

A Mach number and mechanical technology, applied in the direction of machines/engines, mechanical equipment, jet propulsion devices, etc., can solve problems such as large effective use of space, low reliability, increased intake weight, etc., to improve flow coefficient and work The effect of simple performance and actuation mode and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

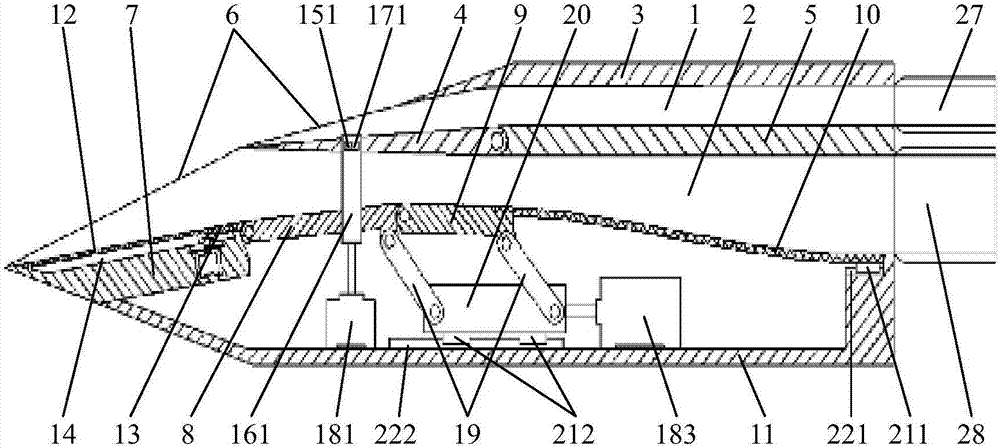

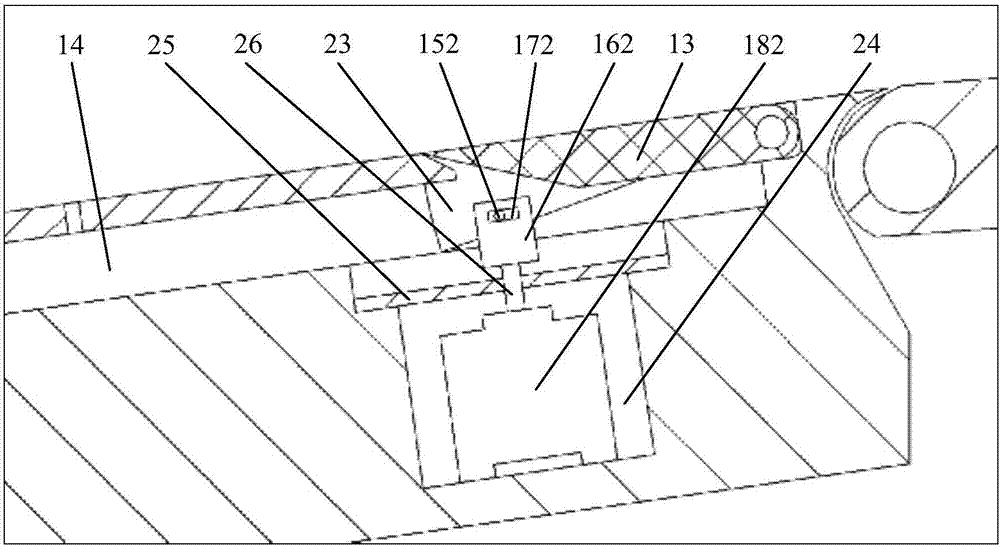

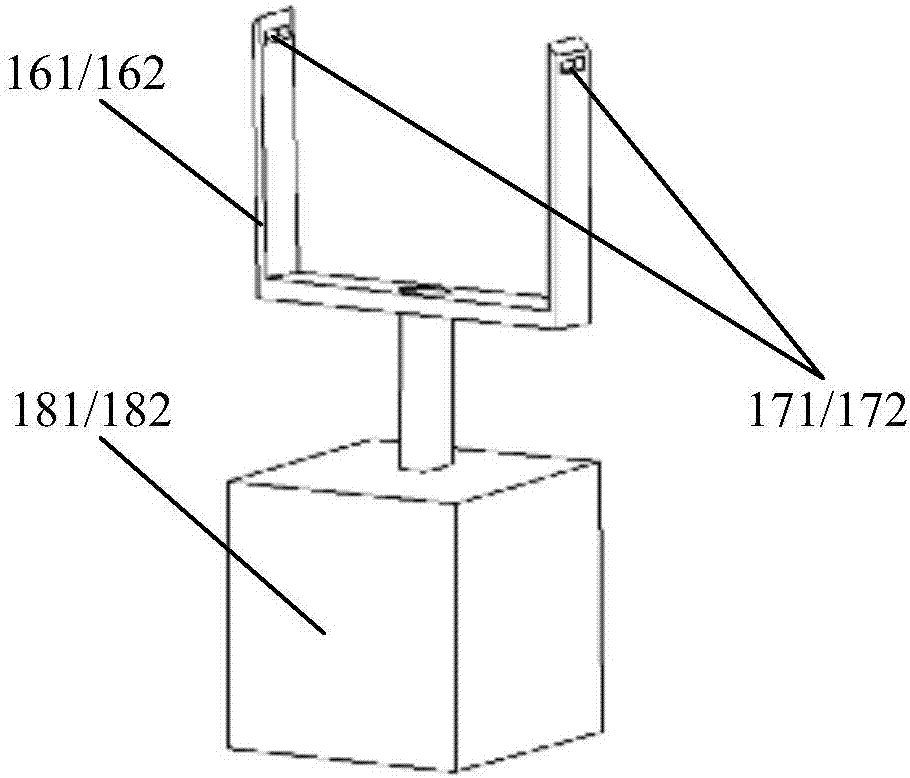

[0020] see figure 1 , figure 2 and image 3, the invention discloses a pneumatic / mechanical combined adjustment Mach number 0-7 combined engine intake port, including a high-speed passage 1 extending from front to rear, located inside the high-speed passage and extending from front to rear side by side with the high-speed passage The low-speed channel 2, the precursor compression surface 7, the side walls 6 located on both sides of the high-speed channel, the low-speed channel and the precursor compression surface, the base 11 located below the precursor compression surface and extending backward, located between the high-speed channel and the low-speed channel The high-speed / low-speed passage divider 5 between the high-speed passage and the rotating lip cover 4 that is hinged at the front end of the divider divider and extends forward; The engine 27 is connected, the inner wall of the low-speed channel 2 is a mechanical variable geometry component, and the outlet of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com