Rain perforated strainer with adaptive opening and closing drainage function

A rain grate and self-adaptive technology, applied in the direction of drainage structures, waterway systems, water supply devices, etc., can solve the problems of not being able to isolate odor and rodents, poor drainage, etc., and achieve the goal of not being easily damaged by pressure and increasing the load capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

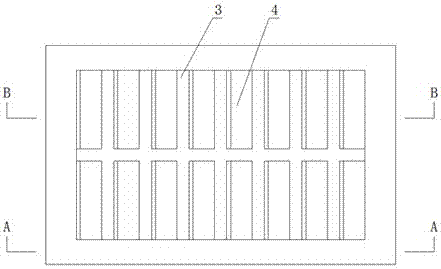

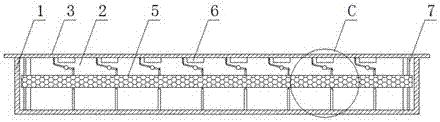

[0028] combined with Figure 1-4 As shown, a rain grate for self-adaptive opening and closing drainage comprises a rectangular frame-shaped main body 2, the periphery of the main body 2 is provided with a shell 1 with a bottom, and the lower end of the main body 2 has no connection with the bottom of the shell 1. Seams are connected to form a hollow cavity. The main body 2 and the housing 1 are covered with a top cover 3. The middle part of the top cover 3 is a rib-shaped beam-shaped grille that protrudes downward. The grille accommodates In the middle of the main body 2, a drain switch 4 is provided at the neutral position of the grille. The drain switch 4 includes blades 42 with cylindrical mounting rods 41 at both ends. The side wall of the main body 2 is provided with a A through hole adapted to the installation rod 41, the installation rod 41 passes through the through hole and is provided with a rocker 10 at the end, the rocker 10 is hinged with a telescopic column 11, a...

Embodiment 2

[0035] On the basis of Example 1, in conjunction with the attached Image 6 As shown, further, the top cover 3 is fixedly connected with the housing 1 and the main body 2, and the end of the installation rod 41 is also provided with a return rod 9, and the return rod 9 is connected to the A return spring 8 is connected between the top covers 2 .

[0036]After the drainage is completed, or the amount of sewage water decreases, the water level in the hollow cavity gradually decreases, and the solid buoyancy device 5 gradually decreases, driving the telescopic column 11 to move down, pulling the rocker arm 10 to rotate, and passing The mounting rod 41 rotates the blade 42 to deflect. After the return spring 8 and the return pull rod 9 are added, the return pull rod 9 and the rocker arm 10 form a lever with the installation rod 41 as a fulcrum, the solid buoyancy device 5 floats up, and the The telescopic column 11 is stretched, the rocker arm 10 rotates up around the fulcrum, t...

Embodiment 3

[0038] On the basis of Embodiment 1, further, one side of the housing 1 and the top cover 3 is hinged through a hinge, and the end of the installation rod 41 is also provided with a return rod 9, and the return rod 9 A return spring 8 is provided at the free end of the return spring 8 , and the other end of the return spring 8 is fixed on the main body 2 .

[0039] After the drainage is completed, or the amount of sewage water decreases, the water level in the hollow cavity gradually decreases, and the solid buoyancy device 5 gradually decreases, driving the telescopic column 11 to move down, pulling the rocker arm 10 to rotate, and passing The mounting rod 41 rotates the blade 42 to deflect. After the return spring 8 and the return pull rod 9 are added, the return pull rod 9 and the rocker arm 10 form a lever with the installation rod 41 as a fulcrum, the solid buoyancy device 5 floats up, and the The telescopic column 11 is stretched, the rocker arm 10 rotates up around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com