Double steam plate garment steamer nozzle

A steam plate and garment ironing technology, applied in the field of garment ironing machines, can solve problems such as inability to press clothes, decrease in efficiency, inconvenient use, etc., and achieve the effect of overcoming the tendency to flutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

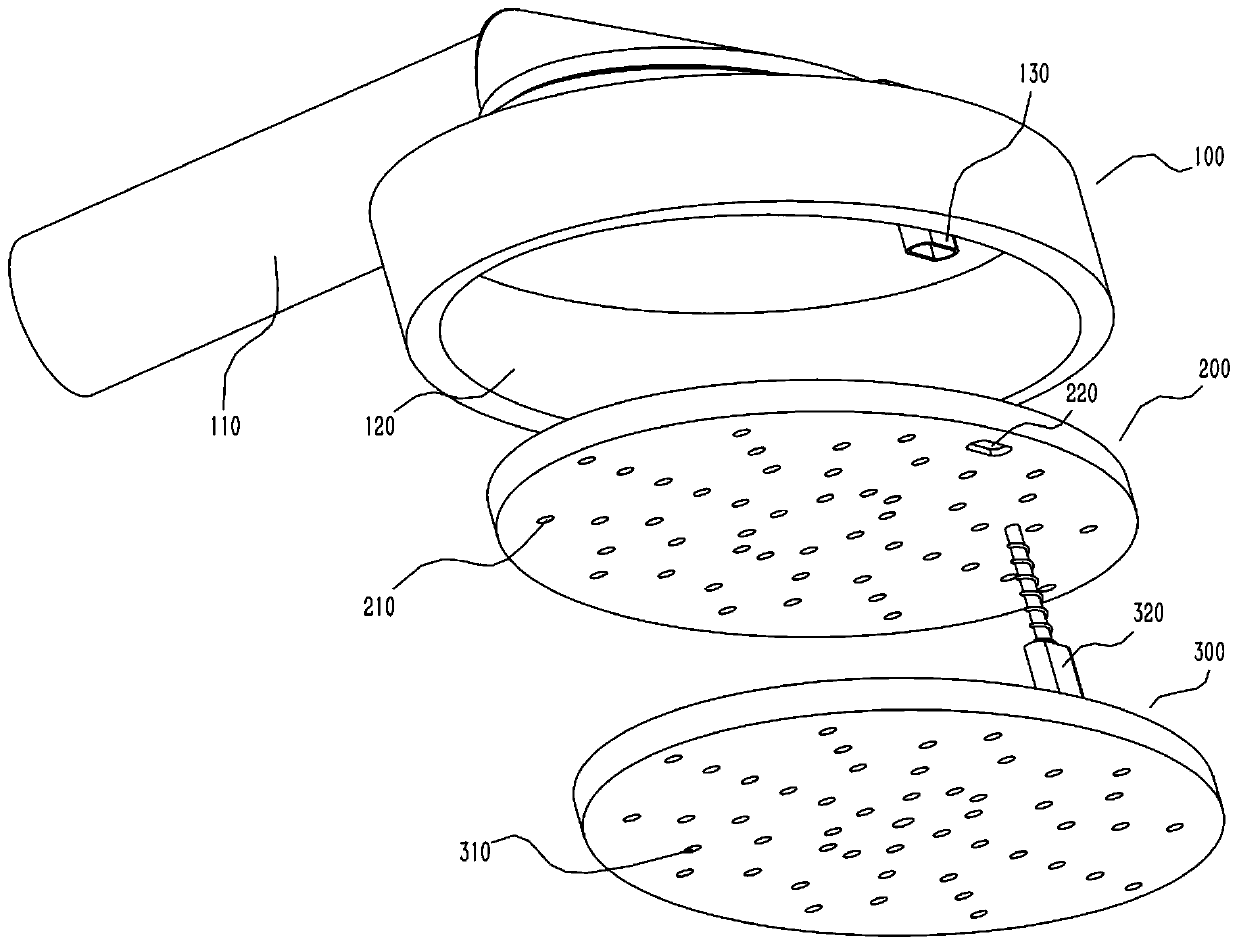

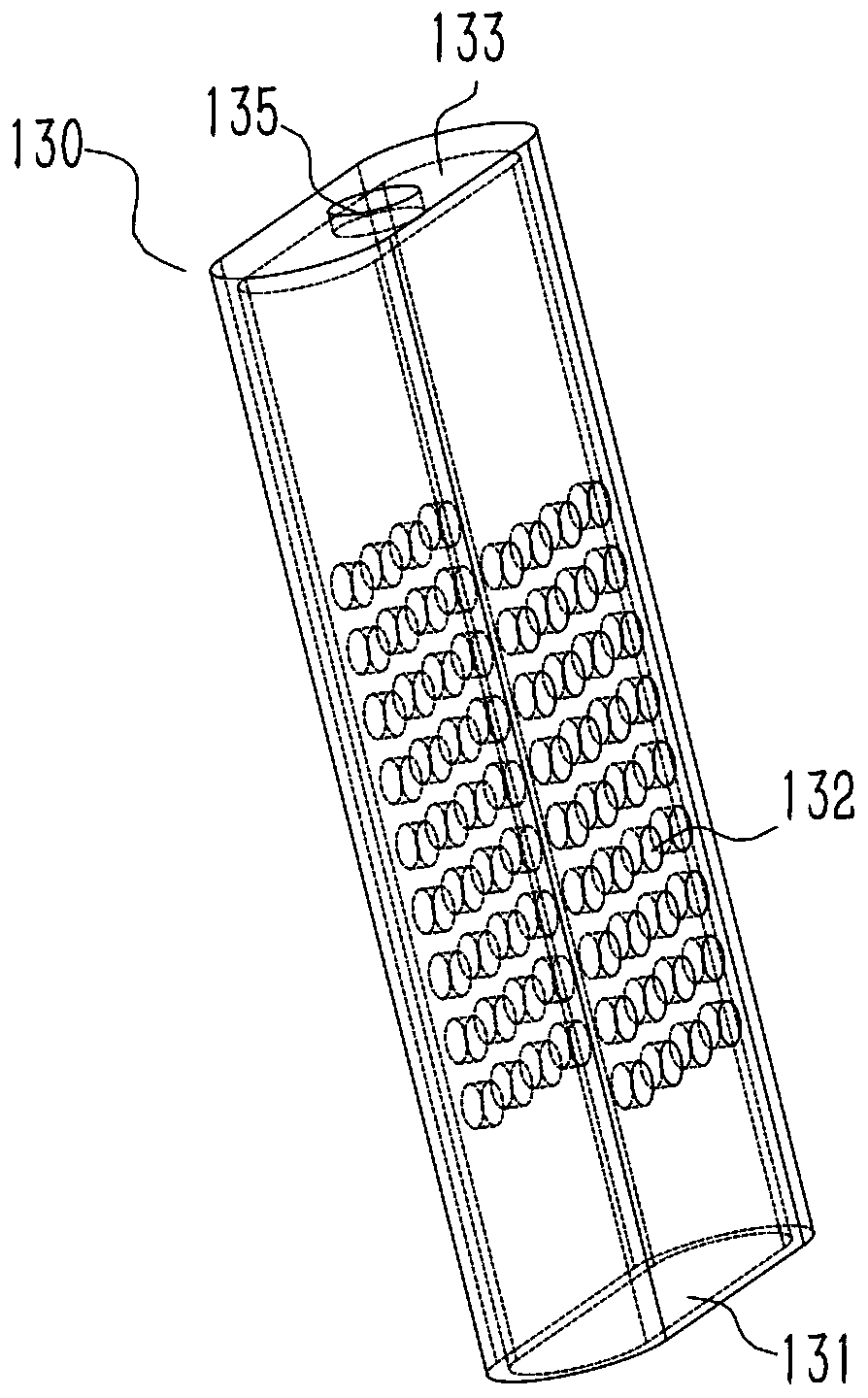

[0032] A spray head of a double steam plate garment ironing machine, comprising: a casing 100 with an air inlet pipe 110 on the upper part, a first cavity in the middle of the casing 100, and a first opening 120 at the lower part of the casing 100 , The air inlet duct 110 and the first opening 120 are both in communication with the first cavity, a sliding pipe 130 is vertically arranged at the lower part of the housing 100, and the first end 131 of the sliding pipe is connected to the first cavity. The cavities are connected, the pipe wall of the slide pipe 130 is provided with a number of vent holes 132, and the second end 133 of the slide pipe is closed; the upper steam plate 200 has a second cavity inside, and the upper steam plate 200 is parallel Is arranged in the first opening 120, the upper steam plate 200 is provided with a plurality of first through holes 210, the first through holes 210 are in communication with the second cavity, and the upper steam plate 200 is provi...

Embodiment 2

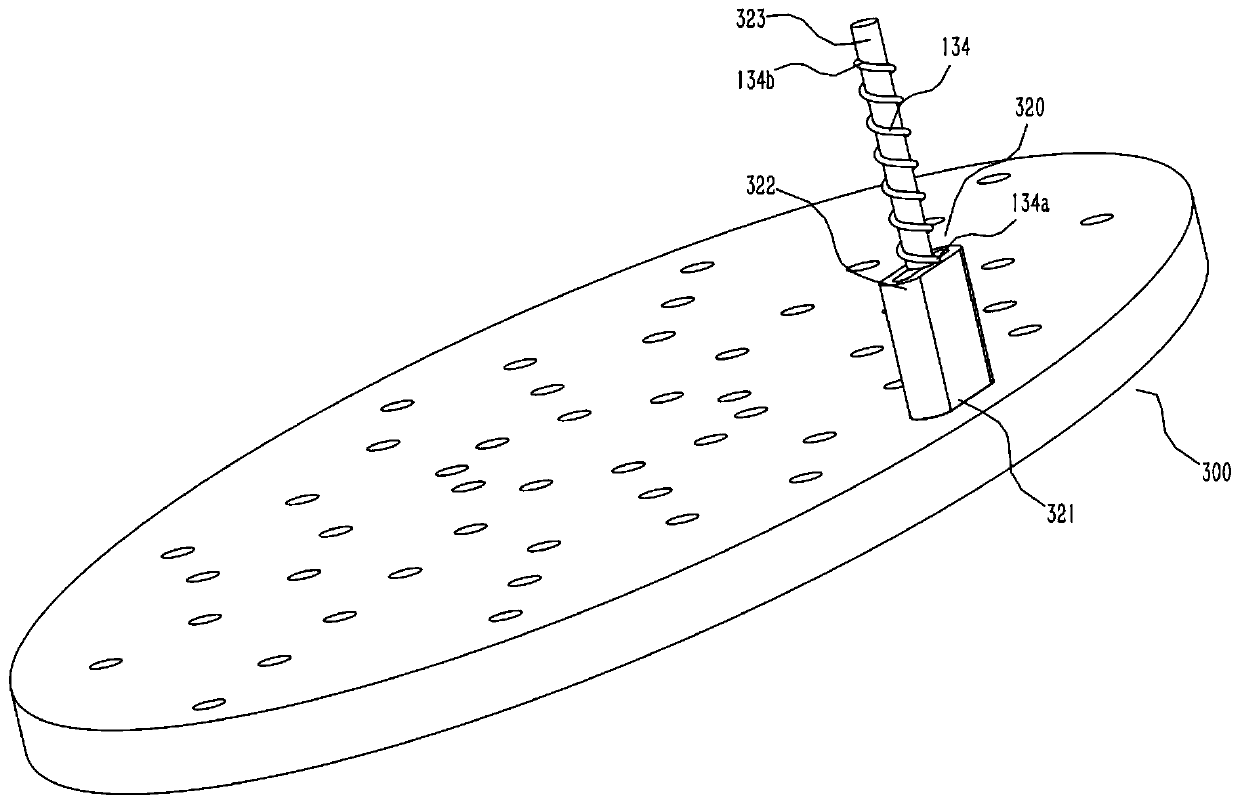

[0037] The slide tube 130 is provided with a first spring 134, the first end 134a of the first spring is fixedly connected to the second end 133 of the slide tube, and the second end 134b of the first spring is connected to the support tube 320 fixed connection. A button 323 is also connected to the second end 322 of the support tube, and the button 323 passes through the first spring 134 and protrudes from the second end 133 of the sliding tube. The second end 133 of the sliding tube is provided with a fourth through hole 135 for the button 323 to pass through. The button 323 is made of heat-insulating material to prevent users from being scalded. The first spring 134 is in a stretched state, so that the lower steam plate 300 always has the power to pull upward. By pressing the button 323, the lower steam plate 300 can be pressed down with the upper steam plate 200 to form a gap as needed, and ironing will be required. Put the clothes in the gap, release the button 323, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com