A method for preparing pd-co-p composite film by electroless plating-replacement

A pd-co-p, chemical plating technology, applied in chemical instruments and methods, liquid chemical plating, chemical/physical processes, etc., can solve problems such as preparation difficulties, achieve simple process, high electrocatalytic activity and durability , the effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in combination with specific embodiments.

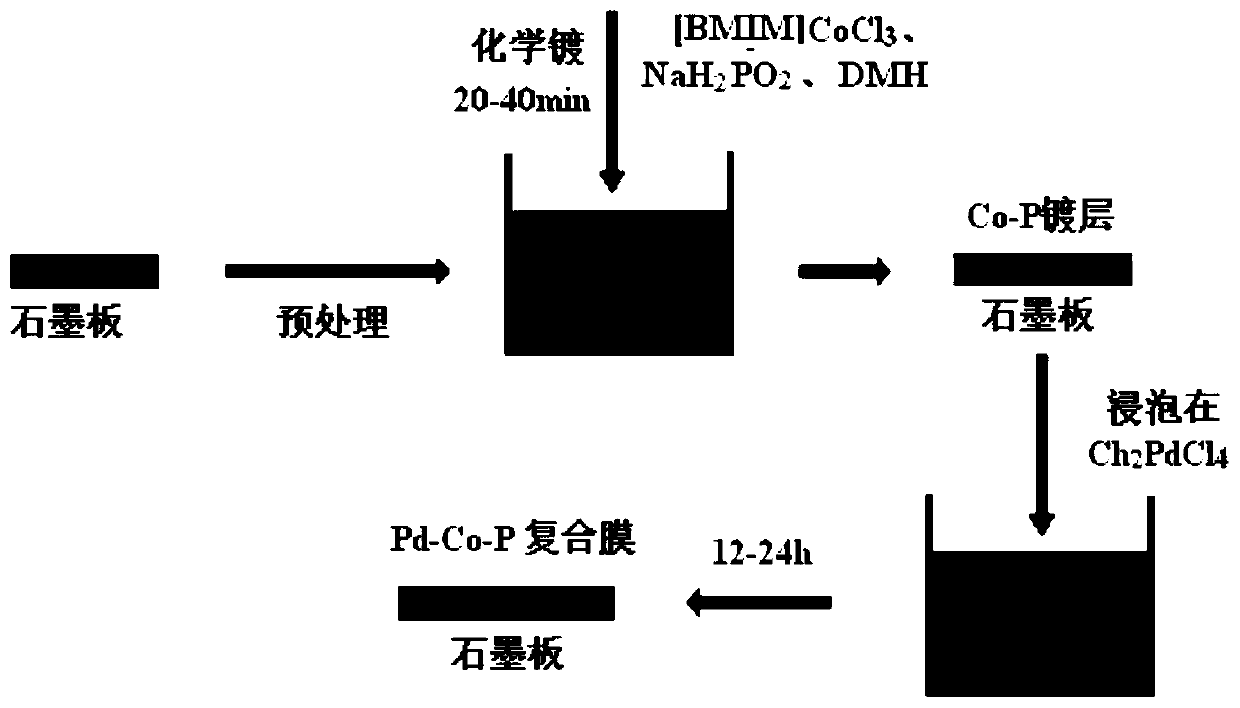

[0023] Step 1, as attached figure 1 As shown, the graphite plate substrate was subjected to pretreatment processes such as alkaline degreasing, pickling, water washing, and drying as a deposition substrate, and 250 mL of ionic liquid 1-butyl-3-methylimidazolium chloride (BMIMCl) was put into the plating substrate. tank, and then add 10g of cobalt-containing ionic liquid [BMIM]CoCl to the ionic liquid 3 , 3g sodium hypophosphite NaH 2 PO 2 And 0.5 grams of dimethylhydantoin (DMH), ultrasonic dispersion, stirring speed is 300 rpm, the temperature is maintained at 85 ° C for electroless plating for 30 minutes; take out the plated parts and wash them with ethanol and deionized water successively, and dry them to get final product Co-P alloy coating.

[0024] Step 2, in an inert gas environment, put the anhydrous low-melting point mixed solvent of 300mL of choline chloride a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com