burner

A technology of burners and diffusion elements, applied in the direction of burners, gas fuel burners, combustion methods, etc., which can solve the problems of performance degradation, dirty holes, clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

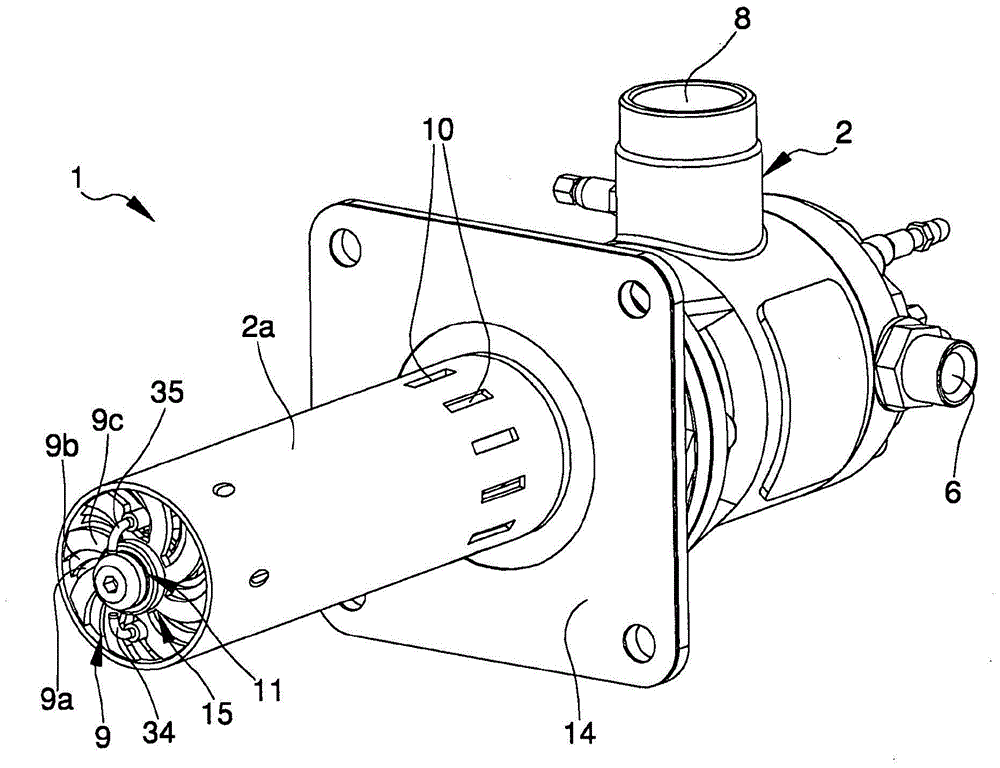

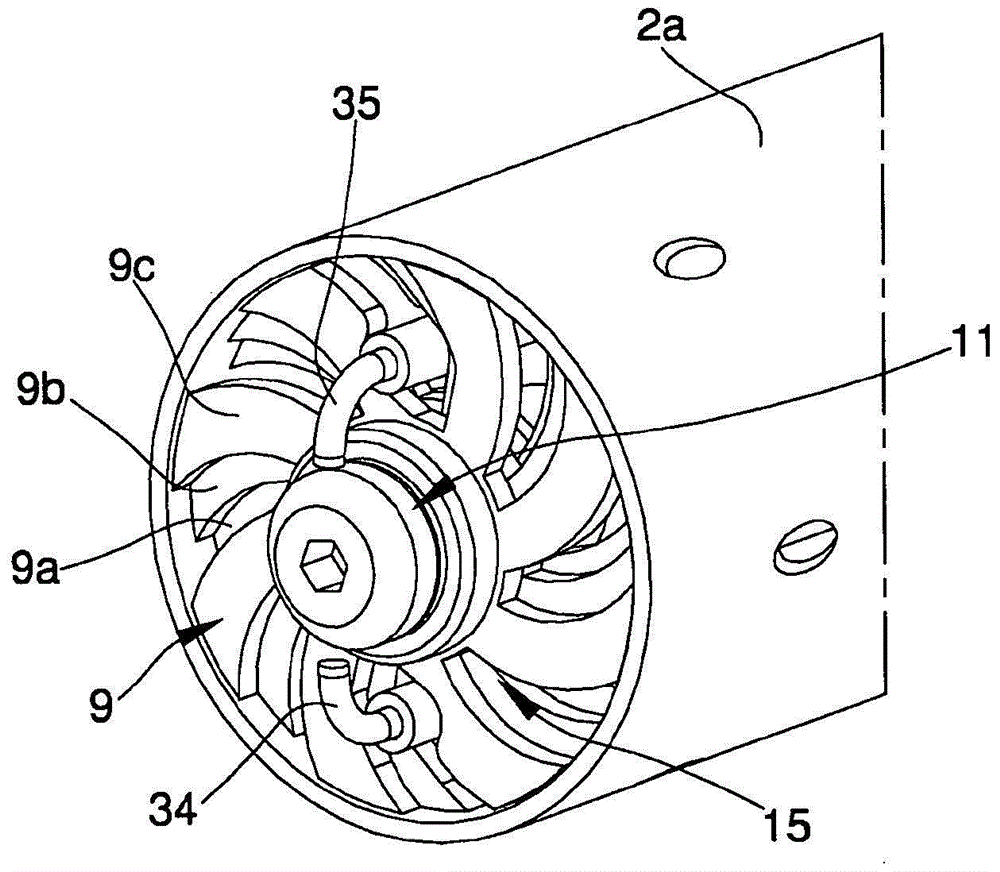

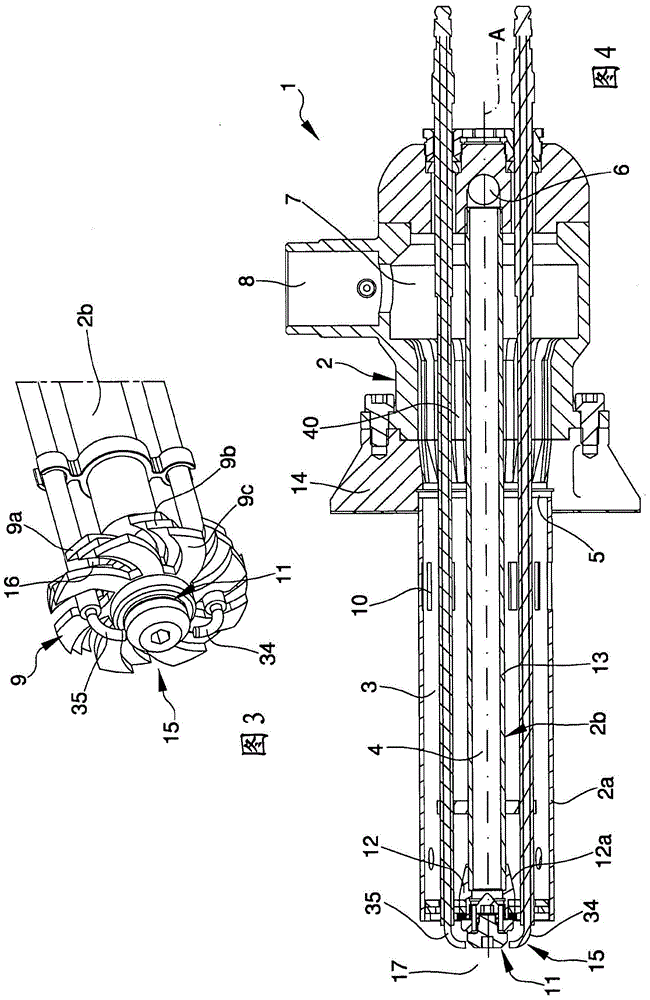

[0037] With particular reference to these figures, a burner according to the invention, indicated throughout by 1, can be used both in the industrial and civil fields.

[0038] The burner 1 comprises a support body 2 defining at least a first duct 3 for supplying a combustible fluid and at least a second duct 4 for supplying a combustion fluid.

[0039] More specifically, the supporting body 2 comprises a first tubular element 2 a defining a first duct 3 and a second tubular element 2 b defining a second duct 4 . The word "tubular" as used herein refers to any internally hollow element, regardless of its cross-sectional shape, which may be of any shape.

[0040] In the illustrated embodiment, the second tubular element 2b is arranged inside the first tubular element 2a. Thus, more specifically, the first duct 3 is delimited laterally by the first and second tubular elements 2a and 2b, while the second duct 4 is delimited laterally only by the second tubular element 2b. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com