Subgrade structure, method and application for deep replacement subgrade of buried pile row subgrade

A subgrade and underground excavation technology, applied to roads, ballast layers, buildings, etc., to ensure smoothness, eliminate settlement and expansion deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

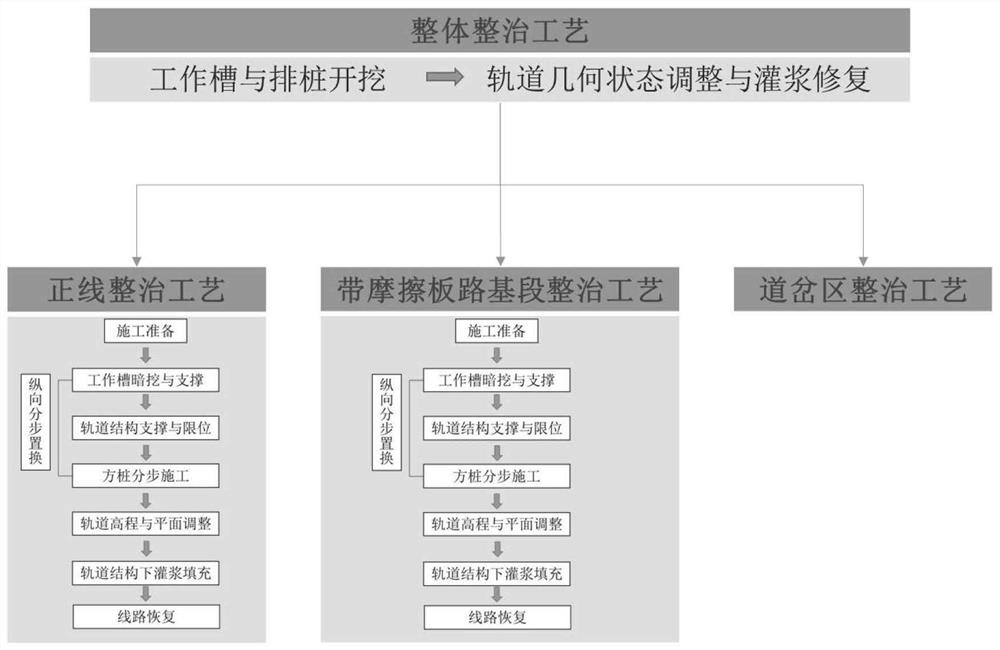

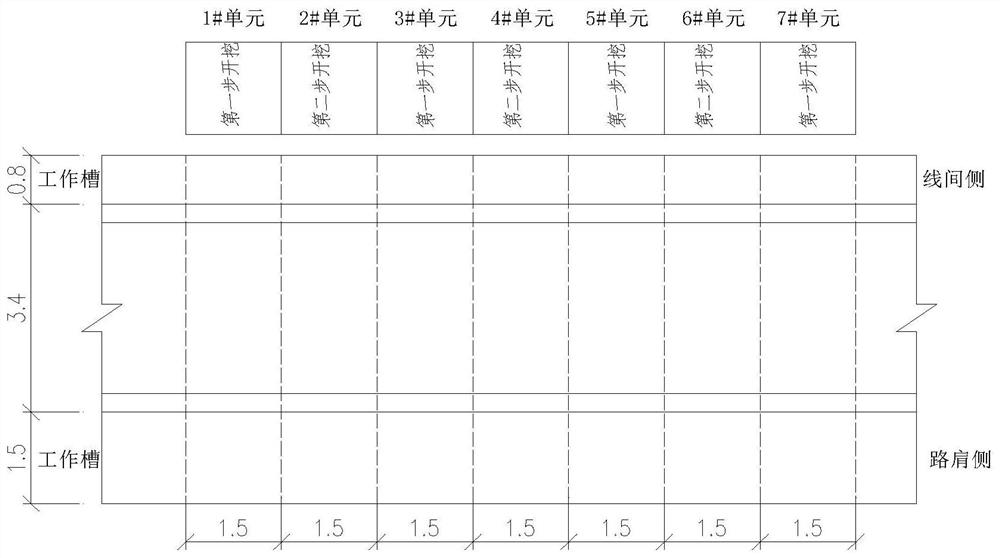

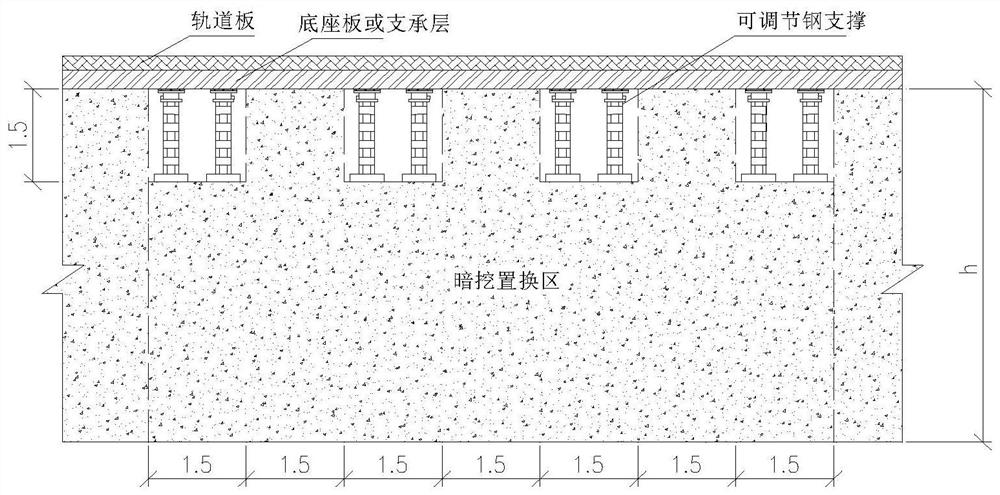

[0046] see figure 1 shown. The invention discloses a method for deep-seated subgrade replacement of subgrade excavated with piles and piles, including overall regulation technology, main line regulation technology, subgrade section regulation technology with friction plates, and turnout area regulation technology. The overall remediation process is a summary of the main line remediation process, the remediation process of the roadbed section with friction plates and the turnout area remediation process. The main line remediation process is the remediation process for the base section of the common main line, and the width of the support layer or base plate is generally 2.8m. -3.4m; the remediation process of the roadbed section with friction plate is the remediation process for the section where the friction plate is set at the bottom of the track structure in the transition section of the road and bridge. The width of the friction plate can reach more than 10m, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com