Charge transfer type automatic oxidation-reduced nano-material as well as preparation method and application thereof, ocean anti-fouling agent and ocean anti-fouling coating

A marine antifouling agent, automatic oxidation technology, applied in antifouling/underwater coatings, epoxy resin coatings, coatings, etc. Fully meet the high anti-fouling requirements, the safety of marine organisms needs to be improved, etc., to achieve significant anti-fouling effect, significantly inhibit adhesion activity, and outstanding anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

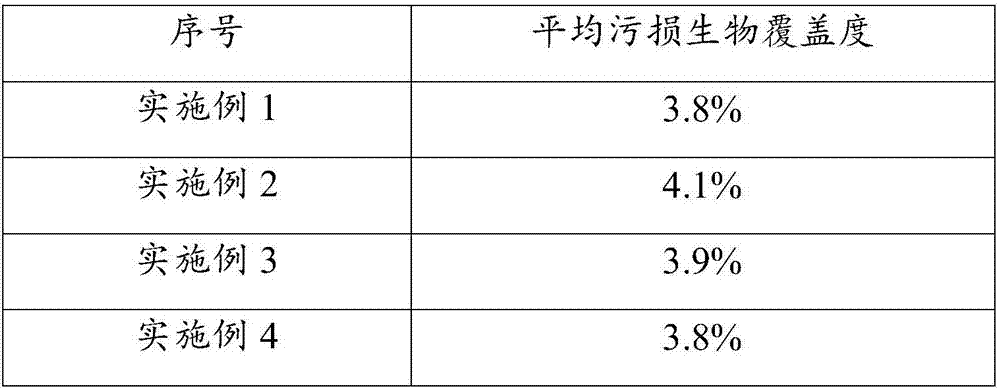

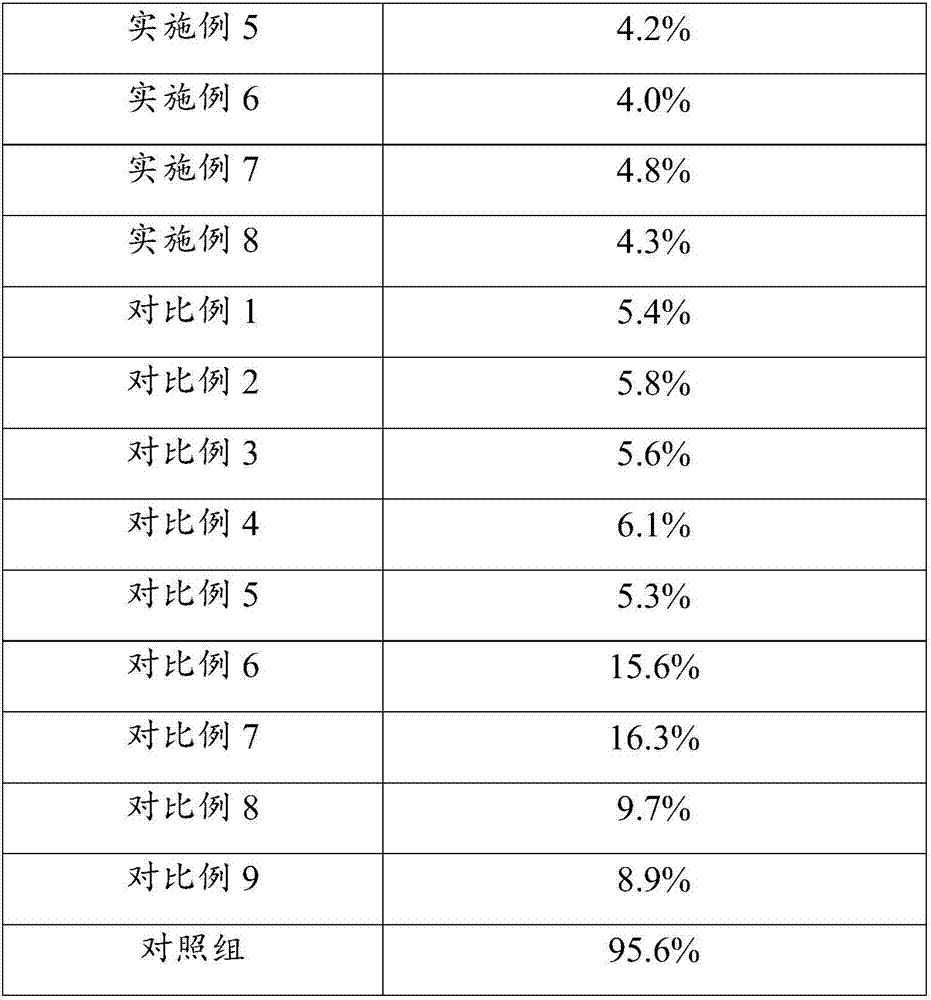

Examples

preparation example Construction

[0091] In a preferred embodiment, the preparation method of the above-mentioned charge-transfer auto-redox nanomaterial comprises the following steps:

[0092] The composite nanomaterial is immersed in a solution containing rare earth elements, and after immersion, drying and roasting are performed to obtain a charge transfer type automatic redox nanomaterial.

[0093] Drying and roasting can be carried out in a conventional manner, for example, drying is carried out in an oven, and roasting is carried out in a muffle furnace.

[0094]The preparation method of the rare earth doped CT nanomaterial of the present invention adopts the impregnation combustion method, which has the advantages of simple process, strong operability, low cost, high product purity, small particle size, uniform rare earth element doping and high activity.

[0095] In a preferred embodiment, the impregnation employs ultrasonic impregnation.

[0096] Ultrasonic impregnation can make the rare earth elemen...

Embodiment 1

[0115] A CT nanomaterial is composed of MnO and TiO doped with rare earth elements La and Ce. 2 , ZnO and SiO 2 The composite nanomaterials are composed of a molar ratio of the main components of MnO:TiO 2 : ZnO: SiO 2 =2:15:1:12, the co-doping amount of rare earth elements La and Ce is 1wt%, and the molar ratio of the two is La:Ce=1:3.

[0116] A certain amount of La(NO 3 ) 3 ·6H 2 O and Ce (NO 3 ) 3 ·6H 2 O is dissolved (the mass of salt is calculated according to the amount of doping), La (NO 3 ) 3 ·6H 2 O, Ce (NO 3 ) 3 ·6H 2 The mixed aqueous solution of O is impregnated into MnO, TiO 2 , ZnO and SiO 2 In the composite nanomaterial, after ultrasonic immersion for 1 h, it was dried at 100 °C, placed in a muffle furnace, and calcined at 600 °C for 8 h to obtain CT nanomaterials.

Embodiment 2

[0118] A CT nanomaterial is composed of MnO and TiO doped with rare earth elements La and Ce. 2 , ZnO and SiO 2 The composite nanomaterials are composed of a molar ratio of the main components of MnO:TiO 2 : ZnO: SiO 2 =2:5:1:5, the co-doping amount of rare earth elements La and Ce is 0.1wt%, and the molar ratio of the two is La:Ce=1:2.

[0119] A certain amount of La(NO 3 ) 3 ·6H 2 O and Ce (NO 3 ) 3 ·6H 2 O is dissolved (the mass of salt is calculated according to the amount of doping), La (NO 3 ) 3 ·6H 2 O, Ce (NO 3 ) 3 ·6H 2 The mixed aqueous solution of O is impregnated into MnO, TiO 2 , ZnO and SiO 2 Among the composite nanomaterials, ultrasonically immersed for 1.5 hours, dried at 80 °C, placed in a muffle furnace, and calcined at 800 °C for 5 hours to obtain CT nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com