Textile goods automatic loading and unloading transportation system loading trolley

An automatic loading and unloading and transportation system technology, applied in the direction of transportation and packaging, arrangement of loading and unloading vehicles, vehicles used for freight, etc., can solve the problems of high labor intensity, non-closed, low efficiency, etc., to reduce labor intensity, ensure neatness, The effect of increasing the loading volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

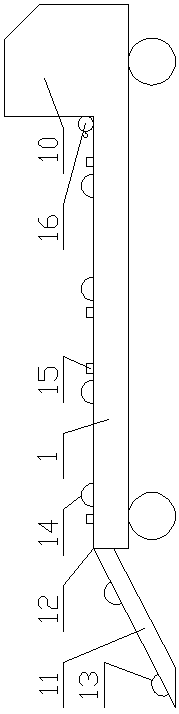

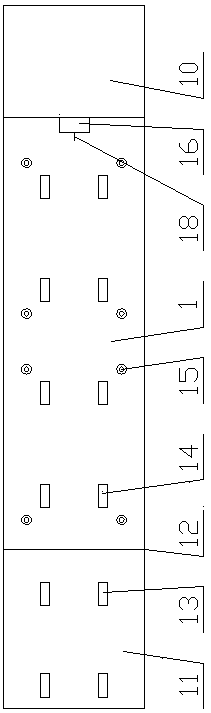

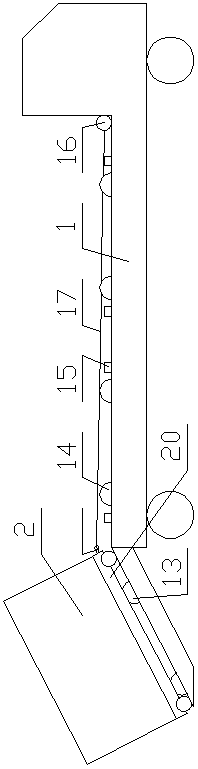

[0038] to combine Figure 1~Figure 8It can be seen that the present invention includes a car body and a loading trolley 2, and the rear end of the floor of the cargo compartment 1 of the car body is swingably connected with a slope plate 11, and the top surface of the slope plate 11 and the top surface of the bottom plate of the cargo compartment 1 are respectively provided with at least There is a row of transmission gears A13 and at least one row of transmission gears B14, the drive motor A is transmitted with the transmission gear A13 through the transmission device A, the drive motor B is transmitted with the transmission gear B14 through the transmission device B, and the drive motor A is fixed On the bottom surface of the ramp 11, the driving motor B is fixed on the bottom of the bottom plate of the cargo compartment 1, and the number of rows of the transmission gear A13 is equal to that of the transmission gear B14; the bottom of the chassis 20 of the loading trolley 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com