High-compression elastic cushion material and application thereof

An elastic cushion, high-compression technology, applied in applications, other household appliances, hydraulic material layered products, etc., can solve the problems of PCCP pipe concrete cracks, low strength, and difficulty in inhibiting PCCP pipe structure deformation and cracks, etc. To achieve the effect of improving the reinforcement effect and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

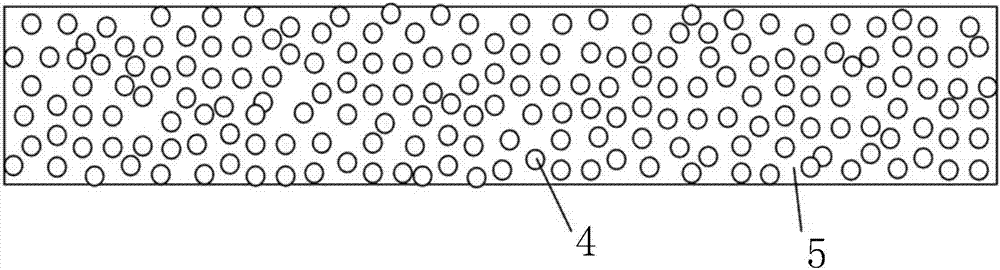

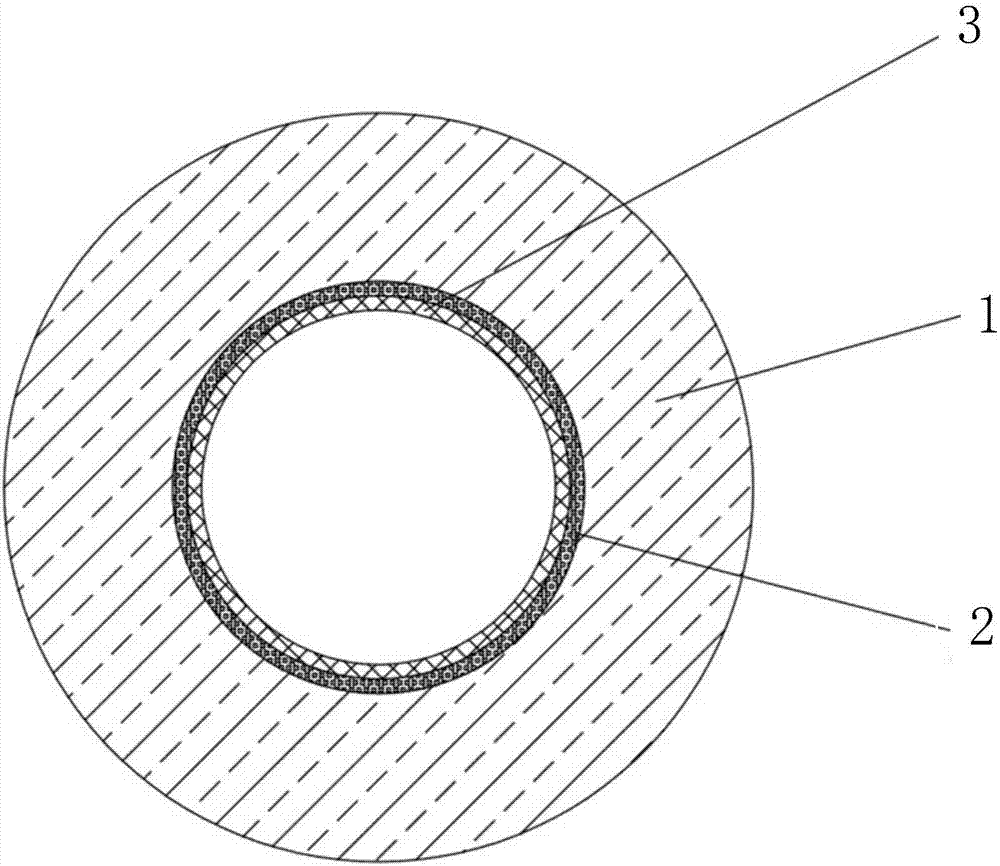

[0024] A high-compression elastic cushion material, its raw material components include single-component polyurea, volatile solvent and polyphenylene particles, and the above raw material components are mixed and solidified to form a layered porous structure, see figure 1 .

[0025] One-component polyurea is a cementing material, and a small amount of volatile solvent is added appropriately. After mixing and dissolving with polyphenylene particles, compared with single-component polyurea curing materials, multiple uniform and independent holes can be formed inside polyurea 5 4, see figure 1 , thus forming a high-compression elastic cushion material, which has the characteristics of compressibility, low elastic modulus, anti-seepage, heat preservation and aging resistance.

[0026] Among them, volatile solvents include propylene glycol methyl ether acetate (PMA) and methyl ethyl ketone (MEK). PMA and MEK have better compatibility with one-component polyurea, can dilute one-com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com