PU solid bicycle tire containing ETPU foaming particles and manufacturing method of PU solid bicycle tire

A technology of foamed particles and a manufacturing method, which is applied to bicycle tires, tire parts, tires, etc., can solve the problems of poor riding comfort, high manufacturing cost, insufficient elasticity, etc. Comfort, weight savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

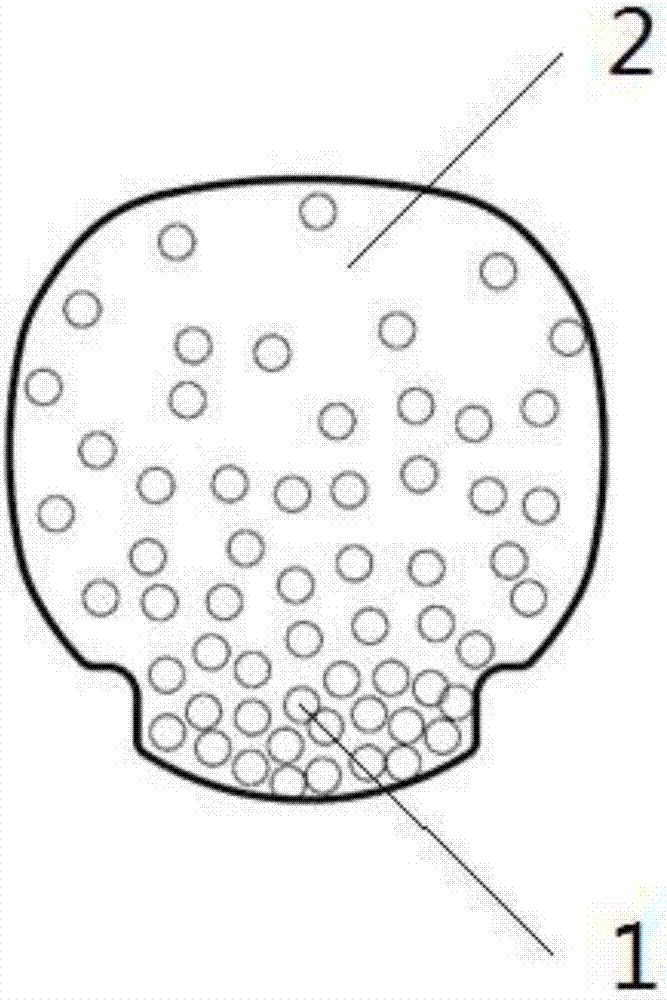

Embodiment 1

[0027] A kind of manufacture method of the PU solid bicycle tire containing ETPU foamed granule of the present invention is as follows: add the ETPU foamed granule of certain volume ratio in advance in the mold of producing PU solid bicycle tire, namely: use existing production PU solid bicycle tire The production equipment (comprising centrifuge and mould) is produced, and in the mold of producing PU solid bicycle tire, adding volume is the ETPU expanded particle of 20% of mould's total volume; Produce the raw material of PU solid bicycle tire (being synthetic microfoaming PU raw material), through the pouring machine, relying on the centrifugal force of the mold to pour into the mold; during centrifugal casting, control the rotation speed of the centrifugal mold (including the centrifuge and the mold) at 1000r / min; The ETPU foamed particles gather to the inner ring of the tire (i.e. most of the ETPU foamed particles gather in the inner ring of the tire); thus the PU solid bic...

Embodiment 2

[0034] A kind of manufacture method of the PU solid bicycle tire containing ETPU foamed granule of the present invention is as follows: add the ETPU foamed granule of certain volume ratio in advance in the mold of producing PU solid bicycle tire, namely: use existing production PU solid bicycle tire The production equipment (comprising centrifuge and mould) is produced, and in the mold of producing PU solid bicycle tire, adding volume is the ETPU expanded particle of 15% of mould's total volume; Produce the raw material of PU solid bicycle tire (being synthetic microfoam PU raw material), through the pouring machine, relying on the centrifugal force of the mold to pour into the mold; during centrifugal casting, control the rotation speed of the centrifugal mold (including the centrifuge and the mold) at 850r / min; The ETPU foamed particles gather to the inner ring of the tire (i.e. most of the ETPU foamed particles gather in the inner ring of the tire); thus the PU solid bicycle...

Embodiment 3

[0041] A kind of manufacture method of the PU solid bicycle tire containing ETPU foamed granule of the present invention is as follows: add the ETPU foamed granule of certain volume ratio in advance in the mold of producing PU solid bicycle tire, namely: use existing production PU solid bicycle tire The production equipment (comprising centrifuge and mould) is produced, and in the mold of producing PU solid bicycle tire, adding volume is the ETPU foaming particle of 18% of mould's total volume; Produce the raw material of PU solid bicycle tire (being synthetic microfoam PU raw material), through the pouring machine, relying on the centrifugal force of the mold to pour into the mold; during centrifugal pouring, control the rotational speed (that is, the speed) of the centrifugal mold (including the centrifuge and the mold) at 900r / min; during pouring, under the action of centrifugal force, The ETPU foamed particles with lower density gather to the inner ring of the tire (that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com