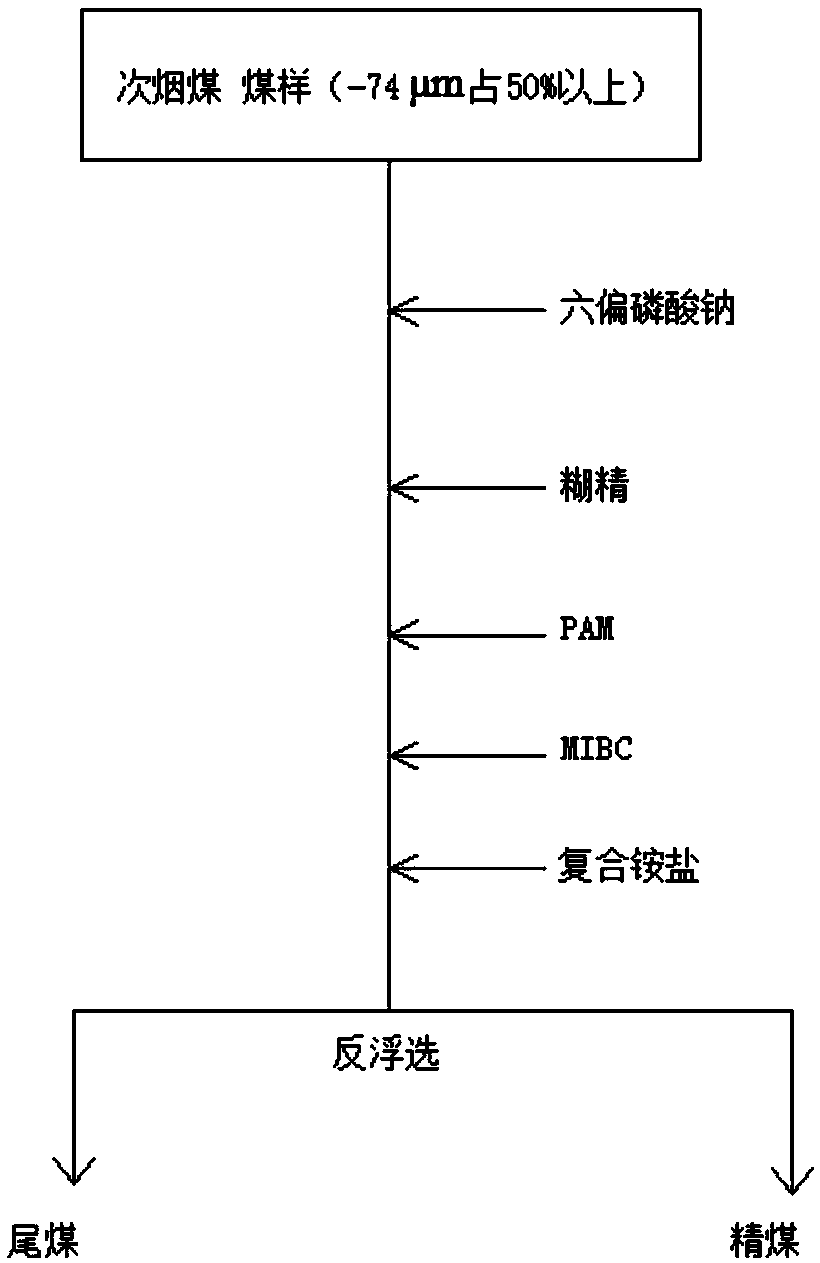

A Method of Selective Flocculation-Reverse Flotation for Ash Reduction of Ultrafine Subbituminous Coal

A sub-bituminous coal and selective technology, applied in the field of mineral processing, can solve the problems of deteriorating the effect of reverse flotation separation, and achieve the effect of improving the effect of reverse flotation, reducing the ash content of clean coal, and achieving good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A certain bituminous coal ash content: 8.81%, moisture: 27.72%, weigh 20g of coal samples with a particle size range of -74μm (ie particle size less than 74μm) accounting for 56.07% and 8.5g of quartz (average particle size 10.42μm) and place them in a 0.5LXFD hanging tank In the selection machine, add distilled water until the overall volume is 0.5L, and the solid concentration is 57g / L; then add sodium hexametaphosphate 1kg / t, and stir for 3min at a speed of 1890r / min; then add inhibitor dextrin 1kg / t, and stir 3min; reduce the speed to 1000r / min, then add non-ionic polymer flocculant (referred to as PAM) 50g / t, stirring time 3min; then add foaming agent methyl isobutyl carbinol (referred to as MIBC) 10ppm, stir 1min ;Finally add collector ammonium salt, the dosage is 1kg / t, at the same time, open the air valve to start inflating, the flotation process officially starts, and the scraping time is 5min.

[0018] The results of this example are: the ash content of clean ...

Embodiment 2

[0020] Take by weighing the same manual mixing feed as in Example 1, coal sample 28g, quartz 12g, place in 0.5LXFD hanging tank flotation machine, add distilled water to 0.5L, solid concentration is 80g / L; Then add hexametaphosphoric acid Sodium 1kg / t, stir for 3min at a speed of 1890r / min; then add inhibitor dextrin 2kg / t, stir for 3min; reduce the speed to 1000r / min, then add non-ionic polymer flocculant 80g / t, stirring time 3min; then add foaming agent methyl isobutyl carbinol 10ppm, stir for 1min; finally add collector compound ammonium salt, the dosage is 0.5kg / t, open the air valve to start inflating at the same time, the flotation process officially starts, scrape foam The time is 5 minutes.

[0021] The results of this example are: clean coal ash content 21.32%, combustible body recovery rate 91.16%, compared with no addition of PAM, the ash content decreased by 3.03 percentage points, and the separation efficiency also increased from 41.13% to 47.47%. It can be seen ...

Embodiment 3

[0023] A certain bituminous coal ash content: 9.32%, moisture: 24.58%, -74μm particle size fraction accounted for 54.87%. The average particle size of a certain quartz is 11.37 μm, and the maximum particle size is 54 μm. Weigh 14g of coal sample and 6g of quartz, put it in a 0.5L XFD hanging tank flotation machine, add distilled water to 0.5L, and the solid concentration is 40g / L; Stir for 3min; then add inhibitor dextrin 1kg / t, stir for 3min; reduce the speed to 1000r / min, then add non-ionic polymer flocculant 20g / t, stir for 3min; then add foaming agent methyl isobutyl Base methanol 20ppm, stir for 1min; finally add collector compound ammonium salt, the dosage is 2kg / t, open the air valve to start inflating at the same time, the flotation process officially starts, and the scraping time is 5min.

[0024] The result of this embodiment is: the ash content of clean coal is 11.64%, and the combustible body recovery rate is 87.58%. Compared with when no PAM is added, the ash con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com