Novel intelligent wind locking device for vertical mill

It is a technology of air lock and vertical mill, which is applied in the direction of grain processing, etc. It can solve the problems of affecting the performance and technical indicators of the mill system, the damage of the non-drive side bearing, and the large amount of stone passing through, so as to ensure the accuracy and responsiveness of the state, and the output The effect of small material resistance and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

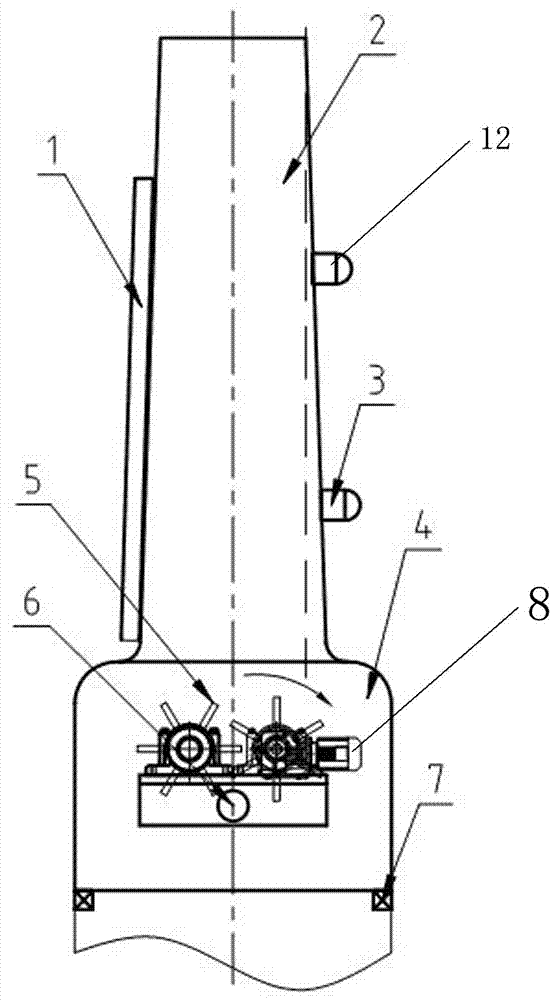

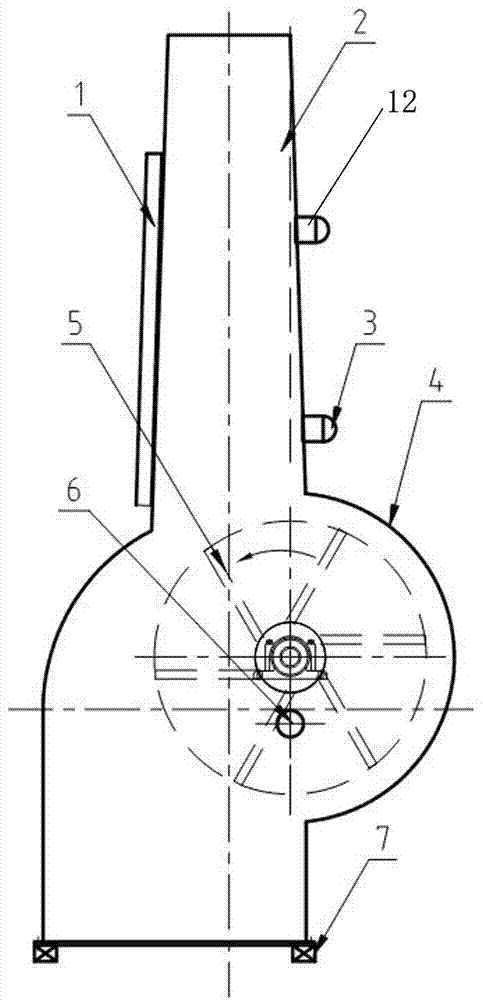

[0022] See attached figure 1 It is an embodiment of the present invention.

[0023] A new type of vertical mill intelligent air lock device, comprising an air lock body 4, an electric control mechanism and a hopper 2 arranged on the upper part of the air lock body 4, the hopper 2 is in the shape of an inverted cone, and the inside of the air lock body 4 runs through There are two shifting rollers 5, the bottom of the hopper 2 outlet corresponds to between the two shifting rollers 5, and the two shifting rollers 5 rotate towards the two sides of the air lock body 4, and the shifting The outer wall of the material roller 5 is evenly provided with multiple rows of saw-toothed material shifting teeth 11, the material shifting teeth 11 are made of 16Mn low-alloy steel plate, and the outside of the tooth end 10 of the material shifting tooth is covered with a Mn13 high manganese steel layer. The two ends of the roller 5 protrude from the wind lock body 4 and are respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com