Method for producing organic-inorganic hybrid membrane by enzyme induction

A hybrid membrane and enzyme-induced technology, applied in the field of membrane separation, can solve the problems of biological enzymes regulating the growth of calcium carbonate and difficulty in meeting water quality requirements, and achieve the effect of enhancing hydrophilicity and improving membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

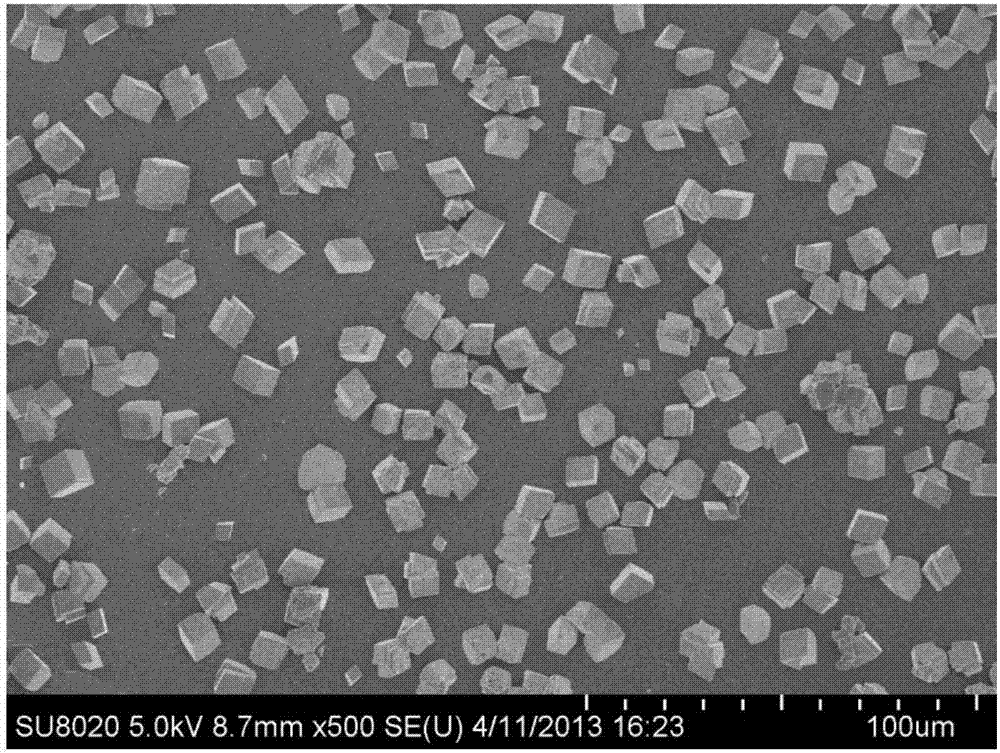

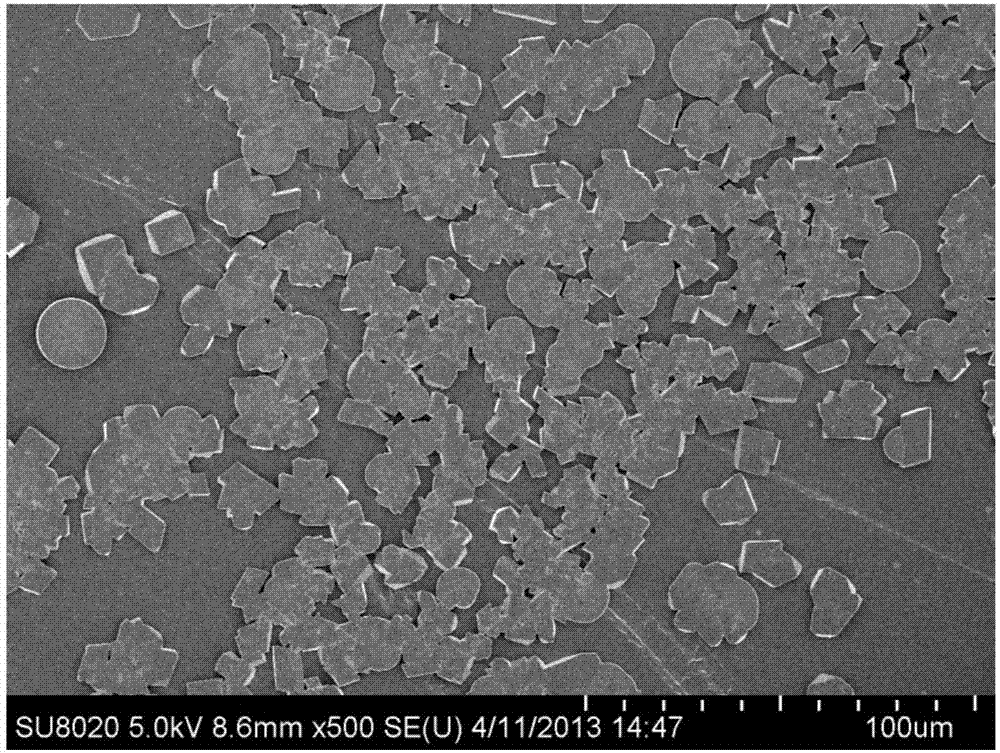

Image

Examples

Embodiment 1

[0043] (1) Polyethyleneimine and sodium polystyrene sulfonate were prepared into 0.1wt% aqueous solution respectively, and after stirring and defoaming treatment, they were prepared into film-making liquid;

[0044] (2) Hydrolyze the PAN base film with 0.2mol / L NaOH aqueous solution at 30°C for 60 minutes, rinse it with deionized water several times, and dry it for use;

[0045] (3) Soak the PAN base film obtained in (2) in polyethyleneimine aqueous solution for 30 minutes to form a polycationic film, and rinse it several times with deionized water;

[0046] (4) Soak the membrane obtained in (3) in an aqueous solution of sodium polystyrene sulfonate for 30 minutes, so that polyanions and polycations react to form a single-layer polyelectrolyte separation membrane, and then rinse several times with deionized water ;

[0047] (5) Preparation of mixed solution

[0048] (a) Prepare polyethyleneimine and sodium polystyrene sulfonate with 0.1wt% aqueous solution respectively, and ...

Embodiment 2

[0060] (1) Polyethyleneimine and sodium polystyrene sulfonate were prepared into 0.1wt% aqueous solution respectively, and after stirring and defoaming treatment, they were prepared into film-making liquid;

[0061] (2) Hydrolyze the PAN base film with 0.2mol / L NaOH aqueous solution at 30°C for 60 minutes, rinse it with deionized water several times, and dry it for use;

[0062] (3) Soak the PAN base film obtained in (2) in polyethyleneimine aqueous solution for 30 minutes to form a polycationic film, and rinse it several times with deionized water;

[0063] (4) Soak the membrane obtained in (3) in an aqueous solution of sodium polystyrene sulfonate for 30 minutes, so that polyanions and polycations react to form a single-layer polyelectrolyte separation membrane, and then rinse several times with deionized water ;

[0064] (5) Preparation of mixed solution

[0065] (a) Prepare polyethyleneimine and sodium polystyrene sulfonate with 0.1wt% aqueous solution respectively, and ...

Embodiment 3

[0077] (1) Polyethyleneimine and sodium polystyrene sulfonate were prepared into 0.1wt% aqueous solution respectively, and after stirring and defoaming treatment, they were prepared into film-making liquid;

[0078] (2) Hydrolyze the PAN base film with 0.2mol / L NaOH aqueous solution at 30°C for 60 minutes, rinse it with deionized water several times, and dry it for use;

[0079] (3) Soak the PAN base film obtained in (2) in polyethyleneimine aqueous solution for 30 minutes to form a polycationic film, and rinse it several times with deionized water;

[0080] (4) Soak the membrane obtained in (3) in an aqueous solution of sodium polystyrene sulfonate for 30 minutes, so that polyanions and polycations react to form a single-layer polyelectrolyte separation membrane, and then rinse several times with deionized water ;

[0081] (5) Preparation of mixed solution

[0082] (a) Prepare polyethyleneimine and sodium polystyrene sulfonate with 0.1wt% aqueous solution respectively, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com