Waste gas treatment equipment and equipment protection method

A waste gas treatment equipment and waste gas technology, applied in the field of environmental treatment, can solve problems such as large maintenance costs, electric leakage, easy oxidation of electronic components, etc., and achieve the effect of preventing water failure and high temperature explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

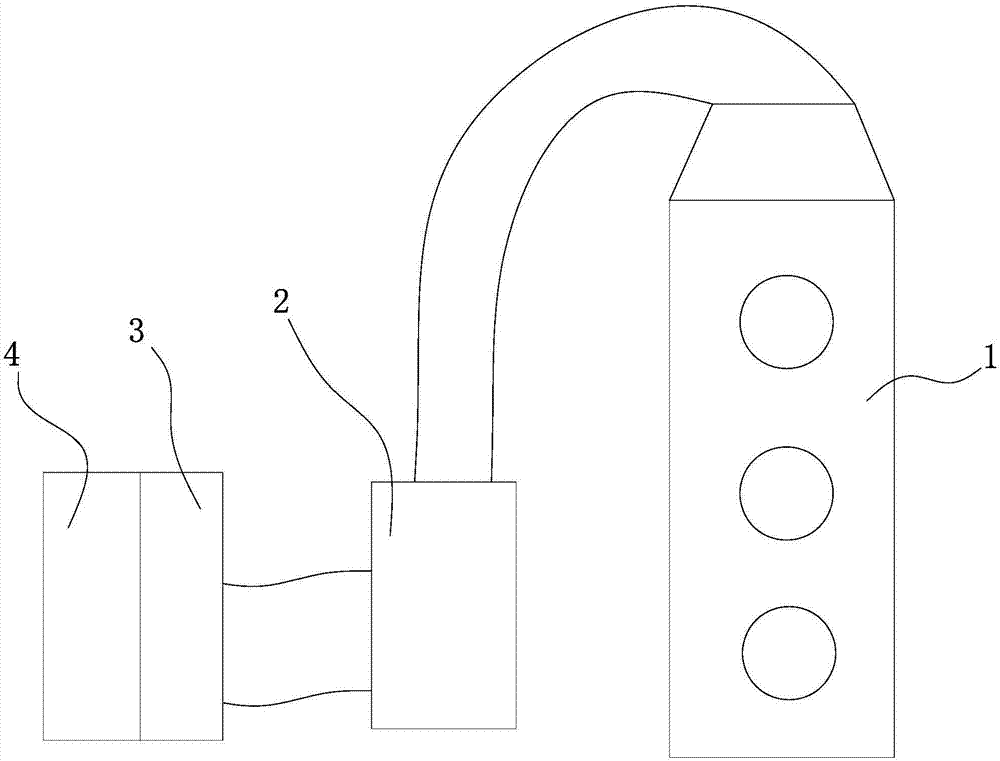

[0030] figure 1 Among them, the present invention comprises the spray tower 1 (prior art) that connects successively, throw away device, low-temperature plasma purifier 3, photo-oxygen catalytic purifier 4 (prior art), spray tower 1 preliminarily purifies waste gas, in The liquid medicine is sprayed in the tower to make it react with the mist of organic matter in the exhaust gas.

[0031] After preliminary purification, the exhaust gas is sucked out from the top of the tower, and enters the detachment device through the pipeline. The detachment device is a centrifugal fan 2, the inlet end of the centrifugal fan 2 is connected to the spray tower 1, and the outlet end is connected to the low temperature Plasma Purifier3.

[0032] The centrifugal fan 2 can dehydrate the exhaust gas from the spray tower 1, and centrifugally dry the water vapor and part of the unreacted organic mist in the exhaust gas, so that the exhaust gas can reach the standard dryness when it enters the low-t...

Embodiment 2

[0046] attached figure 1 It is a schematic diagram of the structure of the present invention, and the present invention includes a spray tower 1 (prior art), a spin-off device, a low-temperature plasma purifier 3, and a photo-oxygen catalytic purifier 4 (prior art) connected in sequence, and the spray tower 1 is preliminary To purify the exhaust gas, spray the potion in the tower to make it react with the organic mist in the exhaust gas.

[0047] After preliminary purification, the exhaust gas is sucked out from the top of the tower, and enters the detachment device through the pipeline. The detachment device is a centrifugal fan 2, the inlet end of the centrifugal fan 2 is connected to the spray tower 1, and the outlet end is connected to the low temperature Plasma Purifier3.

[0048] The centrifugal fan 2 can dehydrate the exhaust gas from the spray tower 1, and centrifugally dry the water vapor and part of the unreacted organic mist in the exhaust gas, so that the exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com