Fertilizer application device of solid particle fertilizer

A fertilization device and a technology of solid granules are applied in the field of fertilization devices of solid granular fertilizers, which can solve the problems of poor control of the application amount, difficulties in storage, transportation and use, and unfavorable mechanical fertilization, so as to improve the overall efficiency and the automatic control rate, The effect of fast and accelerated screening of fertilizers and improved efficiency of fertilizer application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

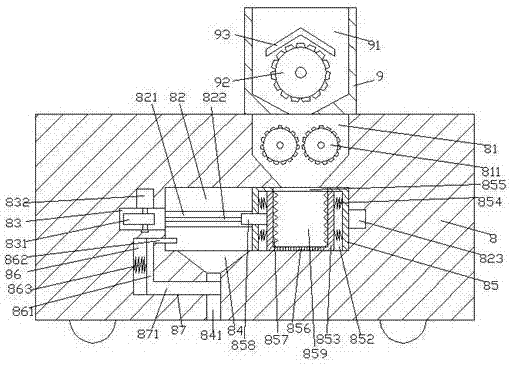

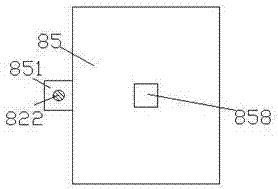

[0018] Such as Figure 1-Figure 4 As shown, a fertilization device for solid granular fertilizer of the present invention includes a fertilization car body 8 and a feeding box 9 installed on the top of the fertilization car body 8, and a feeding chamber 91 is provided in the feeding box 9. The feeding The cavity 91 is provided with a first rotating crushing part 92, and the fertilization car body 8 at the bottom of the feeding box 9 is provided with a crushing cavity 81 whose top communicates with the bottom of the feeding cavity 91. There is a second rotating crushing part 811 symmetrically arranged left and right. The fertilization car body 8 at the bottom of the crushing chamber 81 is connected with a sliding chamber 82 extending to the left. The inner wall of the rear side of the sliding chamber 82 A guide groove 821 is provided, and a threaded rod 822 extends left and right inside the guide groove 821. The left end of the threaded rod 822 is rotated and connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com