Post-optimized joint energy dissipation working body mould

An energy dissipation technology, energy dissipation technology, applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the uneconomical size of wide tail pier, large negative pressure value of overflow dam surface, cavitation cavitation damage of dam surface, etc. problems, to achieve the effect of long maintenance period and small size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

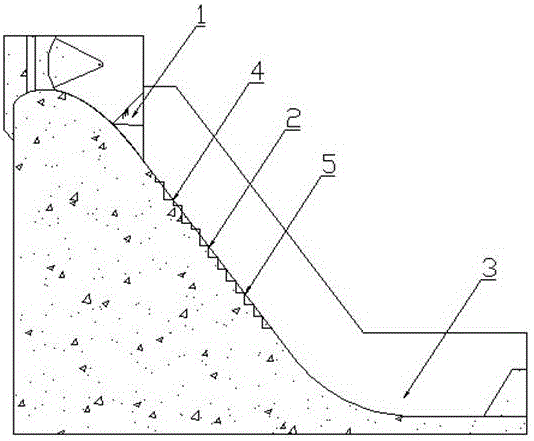

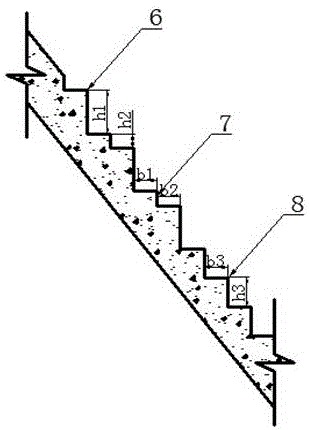

[0017] Embodiment 1: as Figure 1-2 As shown in Fig. 1, an optimized joint energy dissipation body shape, including wide tail pier 1, energy dissipation step 2, and stilling pool 3; wide tail pier 1 is located at the tail of the WES overflow dam face gate pier, and energy dissipation step 2 is located at the dam In the straight section of the overflow dam surface of the body WES, one end of the energy dissipation step 2 is connected to the wide end pier 1, and the other end of the energy dissipation step 2 is connected to the stilling pool 3 through an anti-arc section, and the energy dissipation step 2 includes the energy dissipation step transition section 4 , Energy dissipation step uniform section 5; energy dissipation step transition section 4 is located on the upper part of energy dissipation step uniform section 5, energy dissipation step transition section 4 is a combined step, the height h1 of step I6 is 1m, and the height h2 of step II7 is 1m. The width b1 of I6 is 1...

Embodiment 2

[0019] Embodiment 2: as Figure 1-2 As shown in Fig. 1, an optimized joint energy dissipation body shape, including wide tail pier 1, energy dissipation step 2, and stilling pool 3; wide tail pier 1 is located at the tail of the WES overflow dam face gate pier, and energy dissipation step 2 is located at the dam In the straight section of the overflow dam surface of the body WES, one end of the energy dissipation step 2 is connected to the wide end pier 1, and the other end of the energy dissipation step 2 is connected to the stilling pool 3 through an anti-arc section, and the energy dissipation step 2 includes the energy dissipation step transition section 4 , The energy dissipation step uniform section 5; the energy dissipation step transition section 4 is located at the upper part of the energy dissipation step uniform section 5, the energy dissipation step transition section 4 is a combined step, the height h1 of the step I6 is 1.5m, and the height h2 of the step II7 is 0....

Embodiment 3

[0021] Embodiment 3: as Figure 1-2 As shown in Fig. 1, an optimized joint energy dissipation body shape, including wide tail pier 1, energy dissipation step 2, and stilling pool 3; wide tail pier 1 is located at the tail of the WES overflow dam face gate pier, and energy dissipation step 2 is located at the dam In the straight section of the overflow dam surface of the body WES, one end of the energy dissipation step 2 is connected to the wide end pier 1, and the other end of the energy dissipation step 2 is connected to the stilling pool 3 through an anti-arc section, and the energy dissipation step 2 includes the energy dissipation step transition section 4 , The energy dissipation step uniform section 5; the energy dissipation step transition section 4 is located at the upper part of the energy dissipation step uniform section 5, the energy dissipation step transition section 4 is a combined step, the height h1 of the step I6 is 1.5m, and the height h2 of the step II7 is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com