Method and apparatus for recycling caprolactam organic extraction agent with ultra low energy consumption

A caprolactam and organic solvent technology, applied in the field of rectification, can solve the problems of high energy consumption and increased production cost of caprolactam, and achieve the effect of ultra-low energy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Adopt the first kind of device, the operating method of technological process A is as follows:

[0034] The waste water raw material from the waste water feed tank area A is preheated by the waste water feed preheater 4 and enters the high-pressure waste water stripper 1 for stripping and separation, and the steam at the top of the high-pressure waste water stripper passes through the high-pressure tower top auxiliary condenser 12 (this condenser does not work), pass into medium-pressure tower kettle reboiler 8, pass into phase-separation tank 10 after condensation, phase-separation tank 10 top organic phases are extracted to waste water organic solvent tank area 1, and lower water phase passes through the second A pump 14 pressurizes and enters the high-pressure waste water stripper 1; the liquid phase of the high-pressure waste water stripper 1 tower tank is divided into two stocks, one is returned to the high-pressure waste water stripper 1 after being evaporated by t...

Embodiment 2

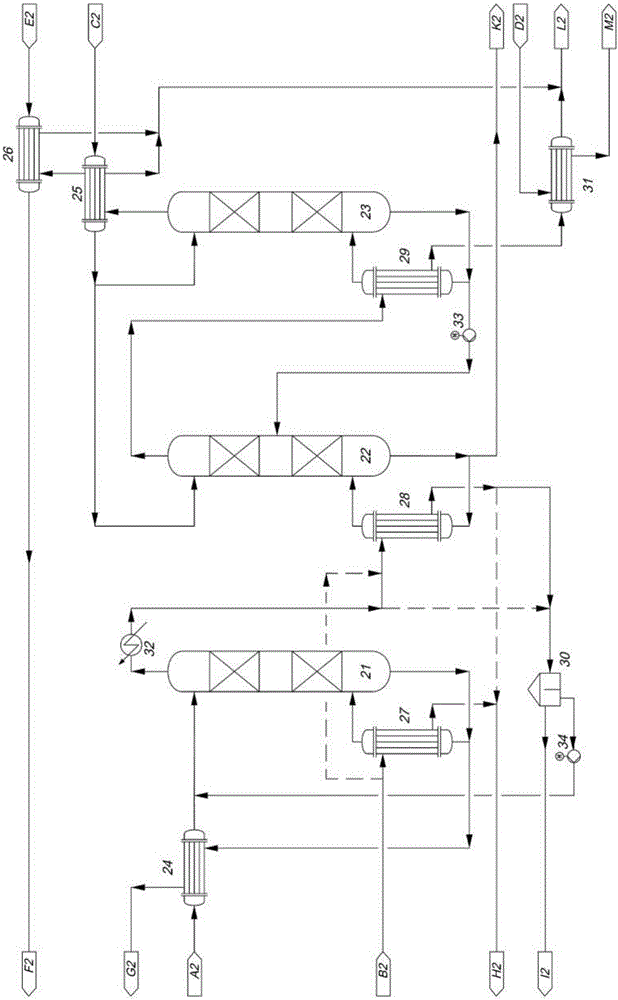

[0044] Adopt the second kind of device, the operating method of technological process B is as follows:

[0045]The waste water raw material from the waste water feed tank area A2 is preheated by the waste water feed preheater 24 and enters the high-pressure waste water stripper 21 for stripping and separation, and the steam at the top of the high-pressure waste water stripper passes through the high-pressure tower top auxiliary condenser 32 (this condenser does not work), pass into medium-pressure tower kettle reboiler 28, pass into phase-separation tank 30 after condensation, phase-separation tank 30 top organic phases are extracted to waste water organic solvent tank area 12, and lower water phase passes through The first pump 34 pressurizes and enters the high-pressure waste water stripper 21; the liquid phase of the high-pressure waste water stripper 21 tower kettle is divided into two stocks, and one part returns to the high-pressure waste water stripper 21 after being eva...

Embodiment 3

[0055] Adopt the first kind of device, the operating method of technological process A (why is two A) is as follows:

[0056] The waste water raw material from the waste water feed tank area A is preheated by the waste water feed preheater 4 and enters the high-pressure waste water stripper 1 for stripping and separation, and the steam at the top of the high-pressure waste water stripper passes through the high-pressure tower top auxiliary condenser 12 , feed into the phase-separation tank 10 after condensation, the organic phase of the phase-separation tank 10 top is extracted to the wastewater organic solvent tank area 1, and the lower water phase enters the high-pressure wastewater stripping tower 1 after being pressurized by the first pump 14; the high-pressure wastewater stripping The liquid phase in the tower kettle of tower 1 is divided into two streams, one is evaporated by the high-pressure tower kettle reboiler 7 and then returned to the high-pressure waste water stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com