Hot press modified by prepress

A technology of hot press and pre-press, which is applied in veneer press, plywood press, lamination, etc. It can solve the problems of small boards and affect the quality of hot pressing of boards, so as to reduce energy consumption, prevent jamming, Consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

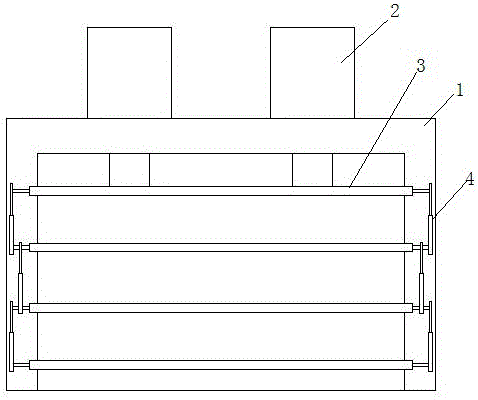

[0015] Such as figure 1 The shown one is a heat press transformed from a pre-press machine, including a door frame-shaped frame 1, and a pressurized hydraulic cylinder 2 vertically installed on the top of the frame 1, and also includes a plurality of horizontally connected to the frame 1 The hot-pressing plate 3, vertical slide rails are respectively provided on the columns on both sides of the frame 1, and the two ends of the hot-pressing plate 3 are respectively slidably connected to the slide rails, and the plurality of hot-pressing plates 3 are vertically arranged , the two ends of each hot pressing plate 3 are respectively provided with reset hydraulic cylinders 4 connected to adjacent hot pressing plates 3, the upper end of the top layer hot pressing plate 3 is connected to the piston rod of pressurizing hydraulic cylinder 2, and the reset hydraulic cylinder 4 and the pressurized hydraulic cylinder 2 are double-acting hydraulic cylinders, the reset control oil circuit of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com