Pipe cutting machine

A technology of pipe cutting machine and transmission mechanism, which is applied in the direction of pipe cutting device, shearing device, shearing machine equipment, etc., can solve the problem that the pipe cutting machine cannot be deployed and cannot be used, and achieves easy reset function, easy pipe cutting, and easy operation. Simple way to effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

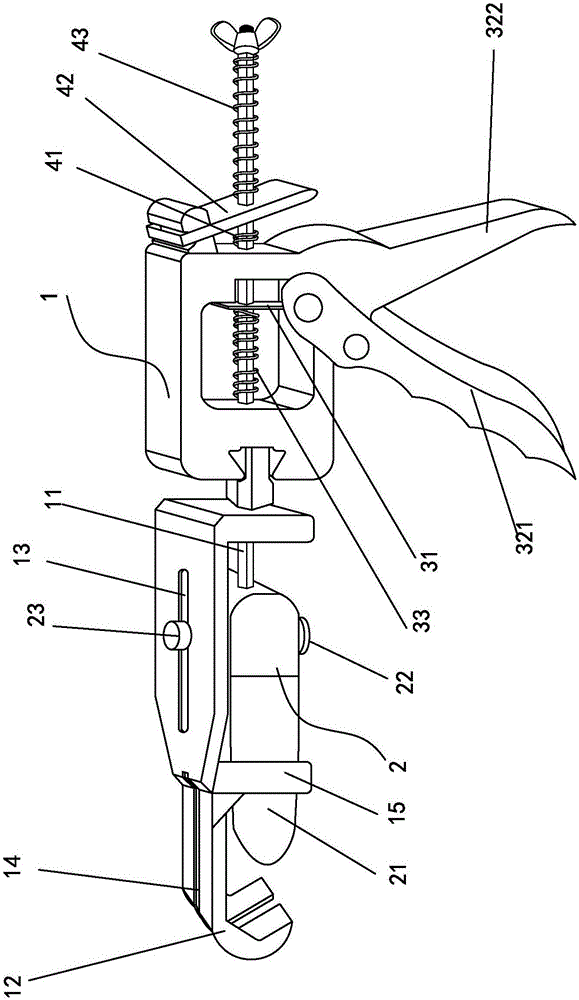

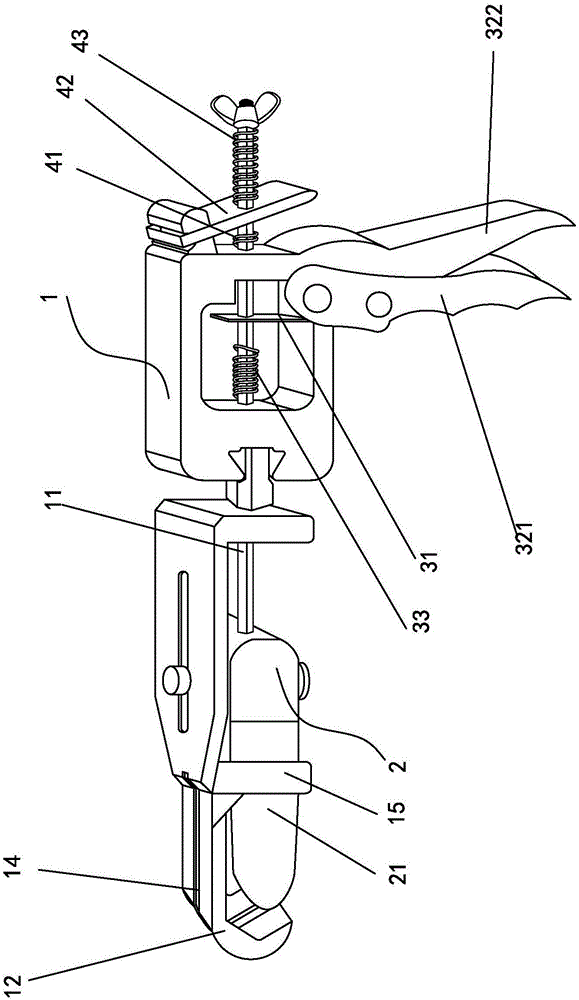

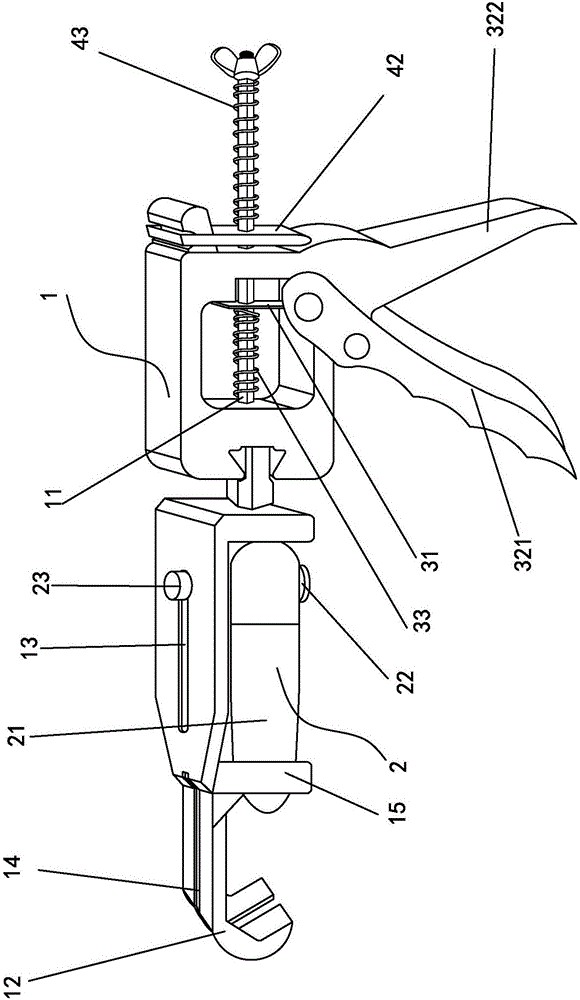

[0028] Embodiment one, see Figure 1 to Figure 3 As shown, a pipe cutting machine of the present invention includes a main body 1, a cutter 2 and a transmission mechanism, the main body 1 is provided with a driving rod 11, the cutter 2 is arranged at the front end of the driving rod 11, and the main body 1 The front end 12 is set as a hook-shaped structure, and the transmission mechanism is connected to the drive rod 11 to drive the drive rod 11 to advance so that the cutter 2 is pressed and cut towards the front end 12 of the hook-shaped structure in the main body 1 to cut the object to be cut; The transmission mechanism includes a transmission piece 31 and an operating handle that is transmission connected to the transmission piece 31 , and the transmission piece 31 is sleeved on the driving rod 11 to drive the driving rod 11 to move.

[0029] The blade 21 of the cutter 2 is an arc-shaped structure protruding outward. In order to improve the cutting force, the apex of the b...

Embodiment 2

[0036] Embodiment two, see Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the cutter 2' is movably arranged at the front end of the drive rod 11, wherein one end of the cutter 2' is pivotally connected to the main body 1, and the other One end is provided with a chute 24, and the front end of the drive rod 11 is slidably arranged in the chute 24; when the transmission mechanism drives the drive rod 11 forward, the cutter 2 rotates and squeezes the object to be cut .

[0037] The front end of the main body 1 is set as a plane, so that it can easily lean against a certain position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com