A kind of flaky copper powder carrying nanometer copper crystals and preparation method thereof

A flake copper powder, nano copper technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of insufficient specific surface area, complicated process, long cycle, etc., and achieve easy availability of raw materials. , the effect of reducing costs and saving time and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

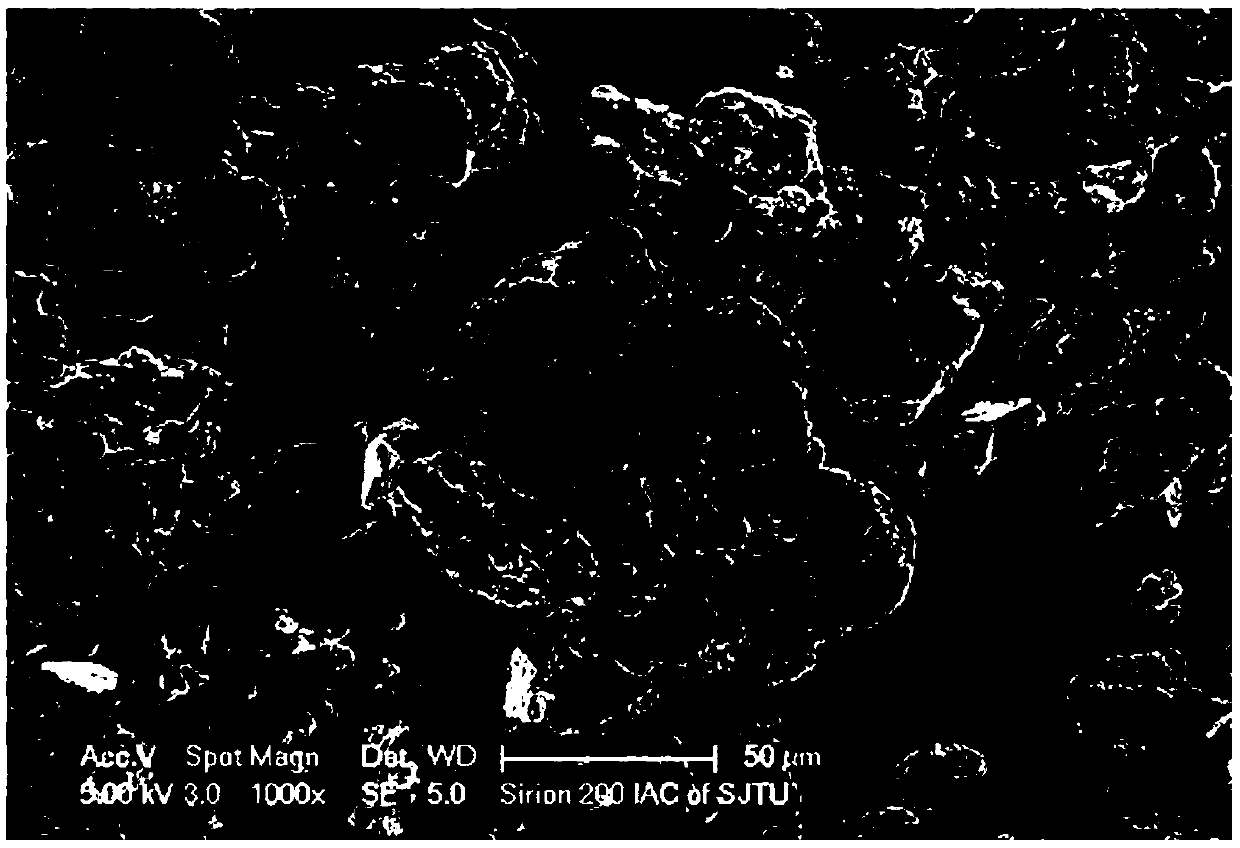

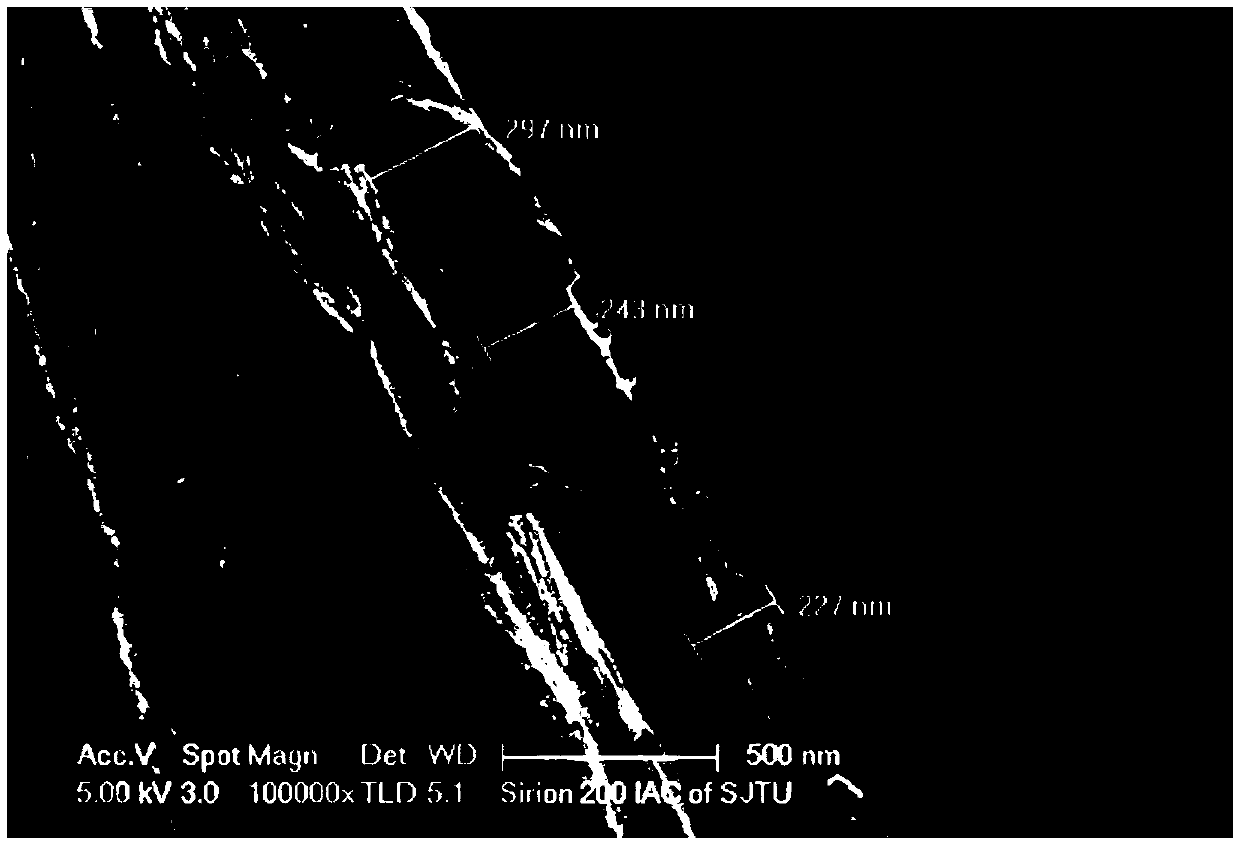

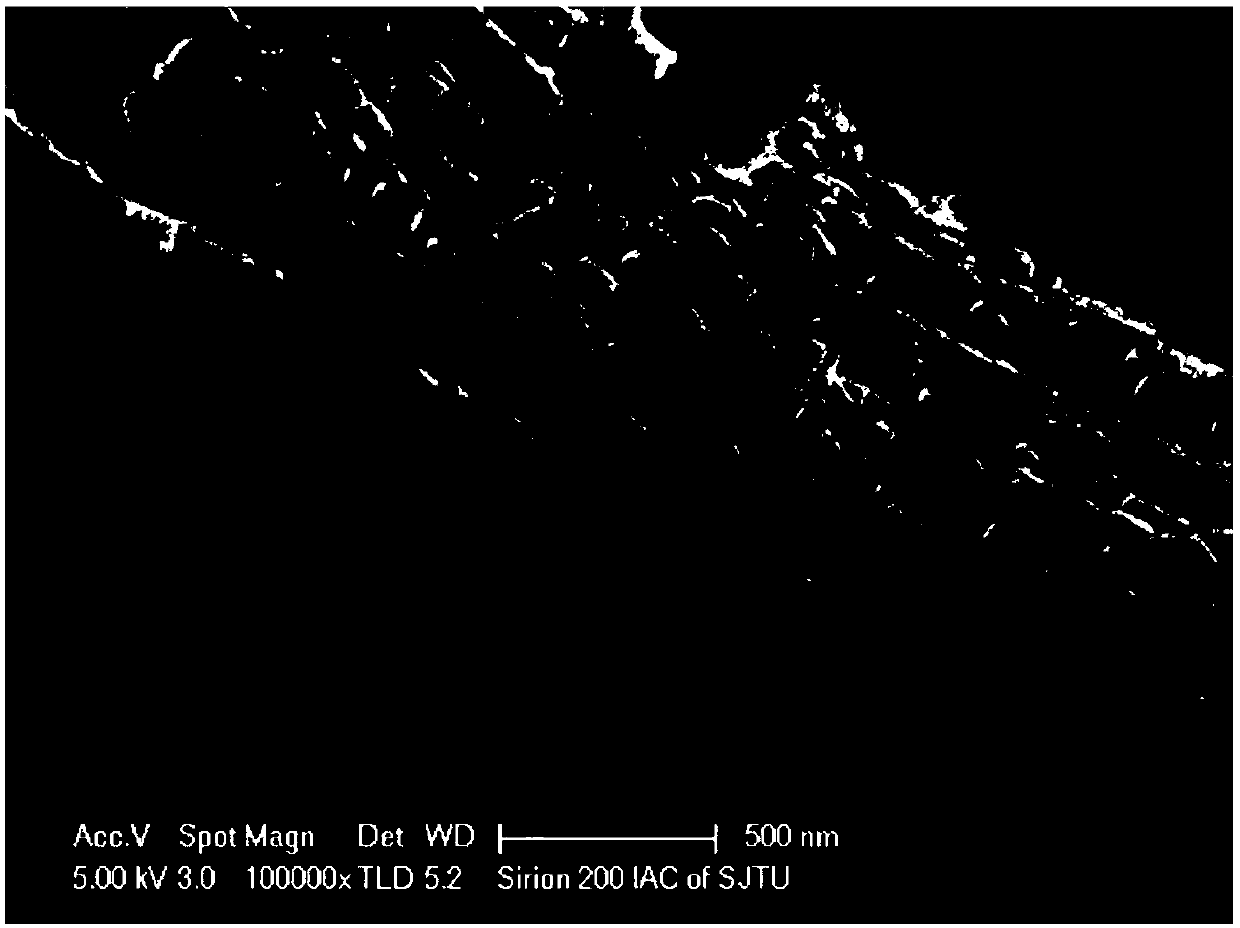

[0037] A preparation method of flake copper powder carrying nano-copper crystals provided by the present invention comprises the following steps:

[0038] Step 1, mixing copper powder and aluminum powder with a volume ratio of 1:1 to 1:5, adding a process control agent, and preparing interlayer copper-aluminum alloy composite powder by ball milling;

[0039] Step 2, passivating the copper-aluminum alloying composite powder in step 1 with air to obtain surface-oxidized copper-aluminum alloying composite powder;

[0040]Step 3. Dealloying the copper-aluminum alloying composite powder in step 2 with an acid solution to remove the aluminum metal in the copper-aluminum alloying composite powder to obtain dealloyed copper powder;

[0041] Step 4, washing and drying the dealloyed copper powder obtained in step 3 to obtain flaky copper powder carrying nano-copper crystals.

[0042] In a preferred embodiment of the present invention, in step 1, the volume ratio of copper powder to alu...

Embodiment 1

[0069] Step 1, get the copper that volume ratio is 3:7, aluminum element powder, gross weight is 50g (containing 21g aluminum powder and 29g copper powder), add the stearic acid that weight is 0.35g in mixed powder; Above-mentioned mixed powder Put into a stainless steel ball mill tank with a volume of 500mL, add 500g of stainless steel balls with a diameter of 16mm, cover the ball mill tank and tighten the bolts;

[0070] Step 2. Open the air port of the ball mill tank and put it into the transitional sealed chamber of the vacuum argon glove box, perform the operation of vacuuming and introducing argon gas, repeat three times, and then open the transitional sealed chamber in the glove box protected by the argon atmosphere , close and tighten the air port of the ball mill jar, take out the ball mill jar, put it into the planetary ball mill and fix it;

[0071] Step 3, set the speed of the ball mill to 200rpm, run for 4 hours, and mix the powder;

[0072] Step 4. After the pow...

Embodiment 2

[0085] Step 1, get the copper that volume ratio is 1:1, aluminum element powder, gross weight is 50g (containing 12g aluminum powder and 38g copper powder), add the stearic acid that weight is 0.35g in mixed powder; Above-mentioned mixed powder Put into a stainless steel ball mill tank with a volume of 500mL, add 500g of stainless steel balls with a diameter of 16mm, cover the ball mill tank and tighten the bolts;

[0086] Step 2. Open the air port of the ball mill tank and put it into the transitional sealed chamber of the vacuum argon glove box, perform the operation of vacuuming and introducing argon gas, repeat three times, and then open the transitional sealed chamber in the glove box protected by the argon atmosphere , close and tighten the air port of the ball mill jar, take out the ball mill jar, put it into the planetary ball mill and fix it;

[0087] Step 3, set the speed of the ball mill to 200rpm, run for 4 hours, and mix the powder;

[0088] Step 4. After the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com