Food roaster with temperature sensor

A humidity sensor and baking machine technology, applied in the field of baking machines, can solve the problems of machine damage, large size, and long baking time, so as to facilitate disassembly and assembly, ensure normal operation, and avoid corrosion of the body. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

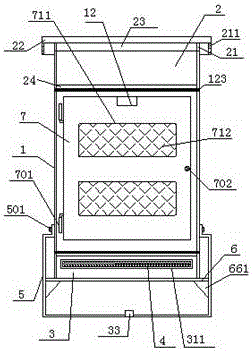

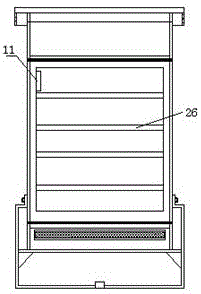

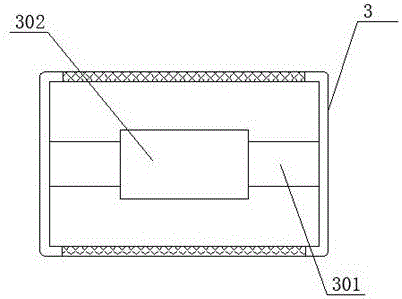

[0024] refer to Figure 1-6 As shown, a food roasting machine with a humidity sensor of the present invention includes a body 1, an upper frame 2 arranged on the body 1, and a lower frame 3 arranged below the body 1. A closed loop 123 is provided between the upper frame body 2 and the body 1 and between the lower frame body 3 and the body 1, and an upper assembly rod 201 is arranged inside the upper frame body 2, and the upper assembly rod 201 is fixedly provided with an exhaust machine 202, the four corners above the upper frame body 2 are respectively provided with supporting blocks 21, the top of the supporting block 21 is fixedly provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com