Differential capacitive sensor applicable to torque detection

A capacitive sensor, differential technology, applied in the direction of instruments, measuring devices, torque measurement, etc., can solve the problems of high price, large size, noise interference, etc., achieve low assembly process difficulty, good anti-interference ability, and improve linearity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further illustrate the present invention below in conjunction with accompanying drawing.

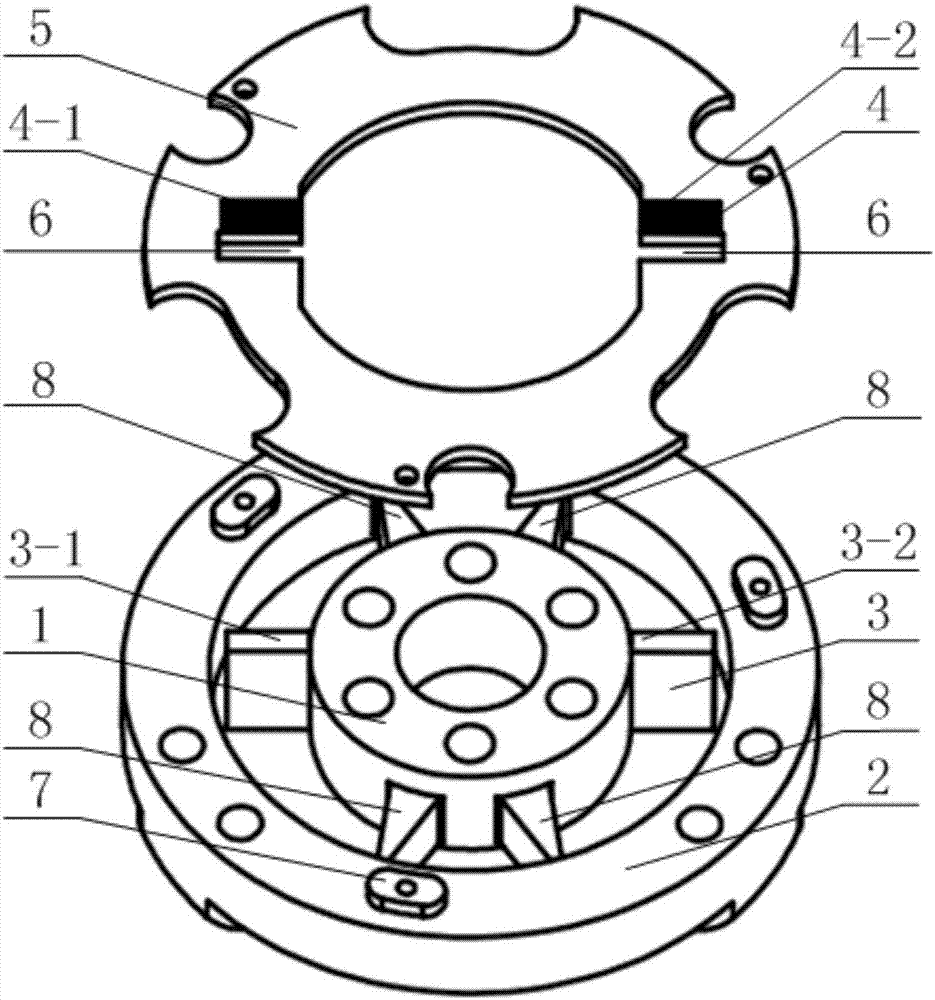

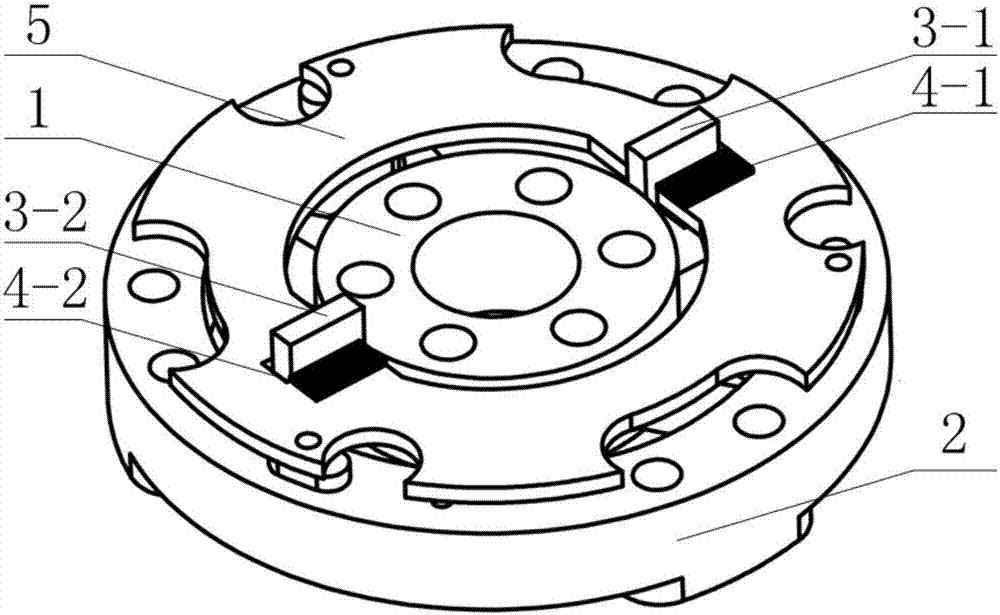

[0018] The present invention is a differential capacitive sensor suitable for torque detection, as attached figure 1 and 2 As shown, it includes at least a torque input disc 1 , a torque output disc 2 , a pair of moving electrodes 3 of inductive capacitors, a pair of static electrodes 4 of inductive capacitors, a substrate 5 and a trapezoidal beam 8 .

[0019] The moving electrode 3 of the sensing capacitor is located between the outer ring of the torque input disc 1 and the inner ring of the torque output disc 2 and is firmly connected with the outer ring of the torque input disc 1; the moving electrode 3 of the sensing capacitor includes the moving electrode of the sensing capacitor 3-1 and the moving electrode 3-2 of the sensing capacitor are distributed symmetrically about the Y axis.

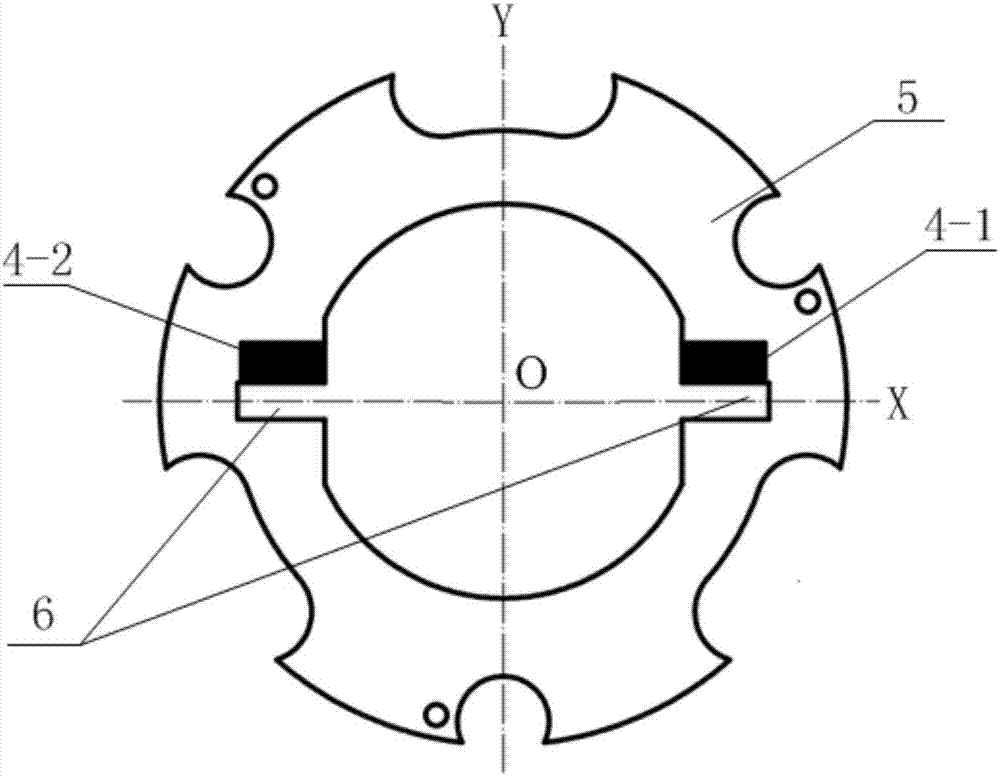

[0020] as attached image 3 As shown, the static electrode 4 of the sensing capacitor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com