A self-adaptive control method for direct injection gasoline engine mixture

An adaptive control and mixture technology, applied in electrical control, engine control, fuel injection control, etc., can solve the problems of deterioration of emission effect, deterioration of engine emission, unevenness, etc., to improve the deterioration of air-fuel ratio and improve emissions. worsening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] specific implementation plan

[0049] Below in conjunction with accompanying drawing, specific implementation method of the present invention is described in further detail:

[0050] The present invention provides a kind of self-adaptive control method of mixture gas of direct-injection gasoline engine, and the whole strategy implementation process takes 200 milliseconds as the calculation step size. The present invention will be described in detail below in conjunction with the accompanying drawings:

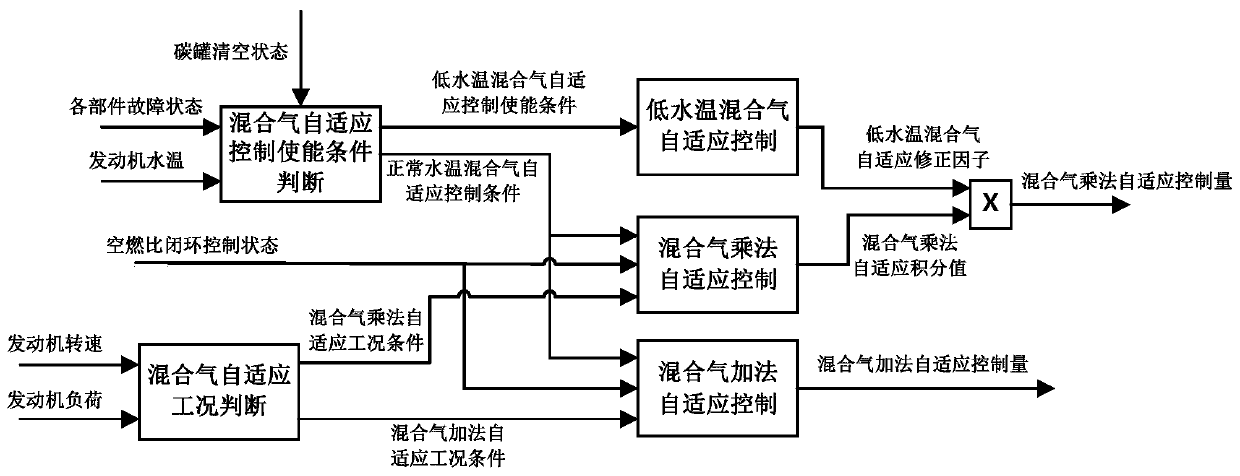

[0051] Step 1. Firstly, judge the basic enabling conditions of the air-air mixture adaptive control according to the state of each component and subsystem of the engine control system. see figure 1 , Figure 4 ; specifically include:

[0052] The judgment of each fault state is calculated by the ECU control software. The fault diagnosis function in the ECU will diagnose whether there is a corresponding fault in the current engine system according to the main sensors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com