Thread trimming mechanism of sewing machine

A thread trimming mechanism and sewing machine technology, applied to the thread cutting mechanism, sewing machine components, sewing equipment, etc. For problems such as high requirements, achieve the effect of stable driving process, improved coordination stability, and low coordination requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

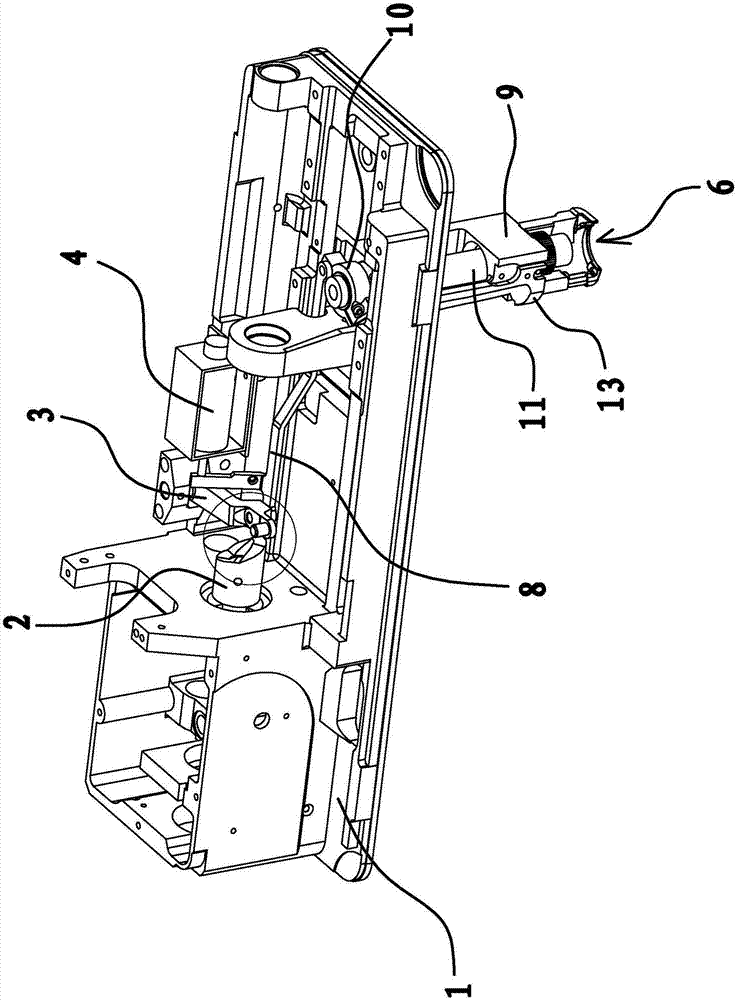

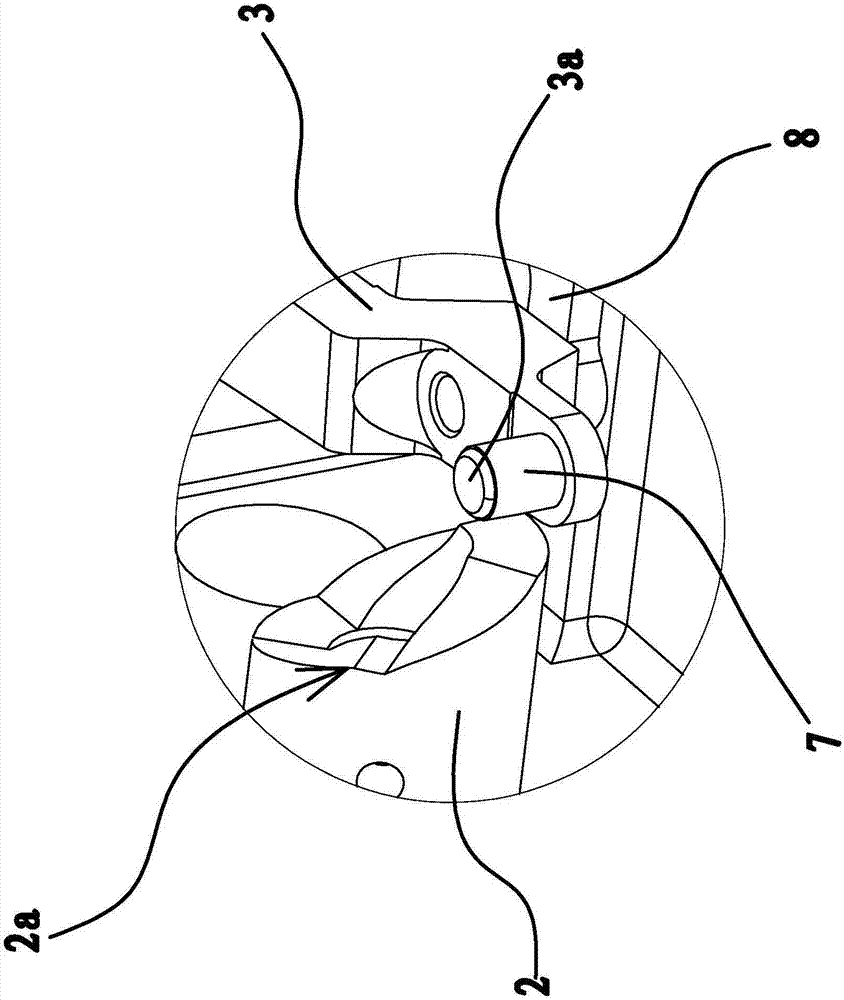

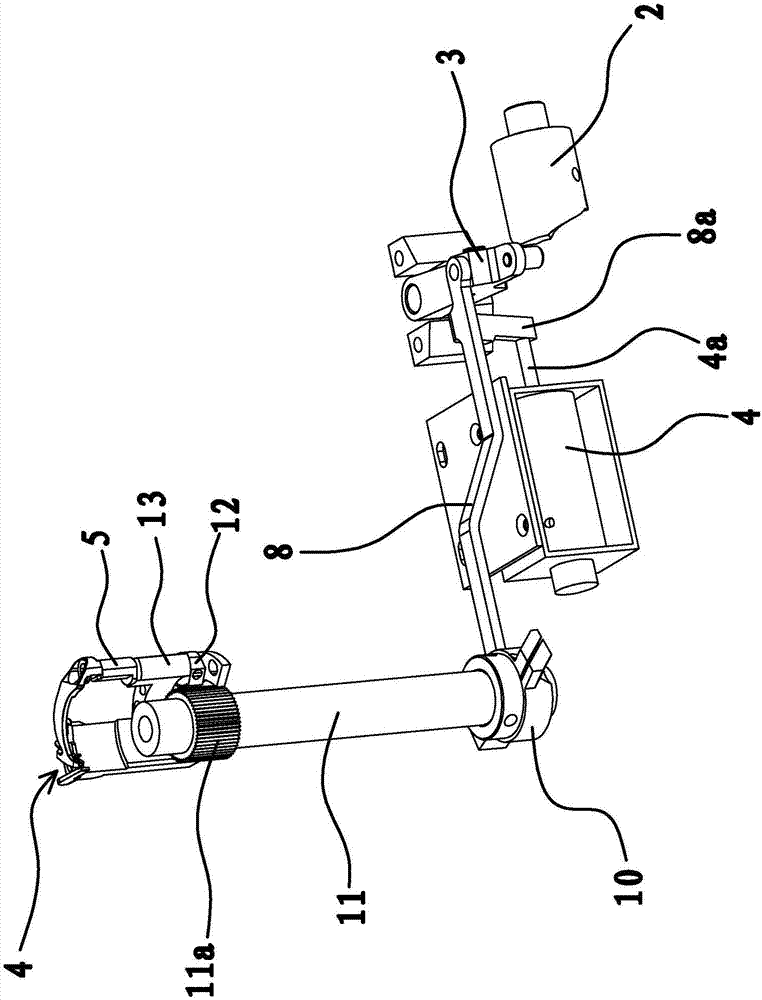

[0037] Such as figure 1 , figure 2 and image 3 As shown, a thread trimming mechanism of a sewing machine comprises a thread trimming cam 2 connected to the motor of the sewing machine, a swing bar 3 hinged on the lower side of the table top 1 of the sewing machine, and a swing bar arranged on the bottom side of the table top 1 of the sewing machine A driver, a pull rod 8, and a thread cutter 6 arranged on the upper side of the table top 1 of the sewing machine. The swing rod 3 is located between the thread trimming cam 2 and the swing rod driver. A swing rod seat is fixed on the lower side of the platen 1 close to the thread trimming cam 2. One end of the swing rod 3 is hinged on the swing rod seat. The other end of the swing rod 3 There is a protruding positioning head 3a on the upper side of one end, and a rolling sleeve 7 is provided outside the positioning head 3a. One end of the pull rod 8 is fixedly connected with the swing rod 3, and the other end of the pull rod 8...

Embodiment 2

[0048] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 8 As shown, in this embodiment, the transmission structure includes a driving gear 15, a transmission gear 12 and a thread cutting shaft 5, the driving gear 15 is arranged on the underside of the table 1 of the sewing machine and the driving gear 15 can rotate relative to the table 1 , The side of the driving gear 15 has a connecting lug 15a, and one end of the pull rod 8 is connected to the connecting lug 15a. The thread cutting moving shaft 5 is worn on the knife rest 9, and the lower end of the thread cutting moving shaft 5 is positioned at the lower side of the platen 1, and the transmission gear 12 is fixed on the lower end of the thread cutting moving shaft 5 and meshes with the drive gear 15. The upper end of thread cutting moving shaft 5 is fixed with 6 seats of thread cutter, and thread cutter 6 is fixed on 6 seats of thread cutter.

...

Embodiment 3

[0051] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 9As shown, in this embodiment, the transmission structure includes a connecting rod 16 and a thread-cutting moving shaft 5. The thread-cutting moving shaft 5 is installed on the tool holder 9, and the lower end of the thread-cutting moving shaft 5 is located on the lower side of the table 1. One end of the connecting rod 16 is fixed with the lower end of the thread cutting moving shaft 5 , and the other end of the connecting rod 16 is connected with an end of the pull bar 8 .

[0052] Because one end of the pull rod 8 is connected with one end of the connecting rod 16, and the other end of the connecting rod 16 is fixed with the lower end of the thread cutting moving shaft 5, the thread cutting moving shaft 5 can rotate relative to the knife rest 9 again, so it can be used as a swing lever 3 When the thread trimming cam 2 swings and drives the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com