Antirust agent and preparing method thereof

A technology of anti-rust agent and catalyst, which is applied in the direction of additives, petroleum industry, lubricating composition, etc. It can solve the problems of high price and unsatisfactory long-term anti-rust and anti-corrosion effect, and achieve long anti-rust validity period and good cleaning performance , excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

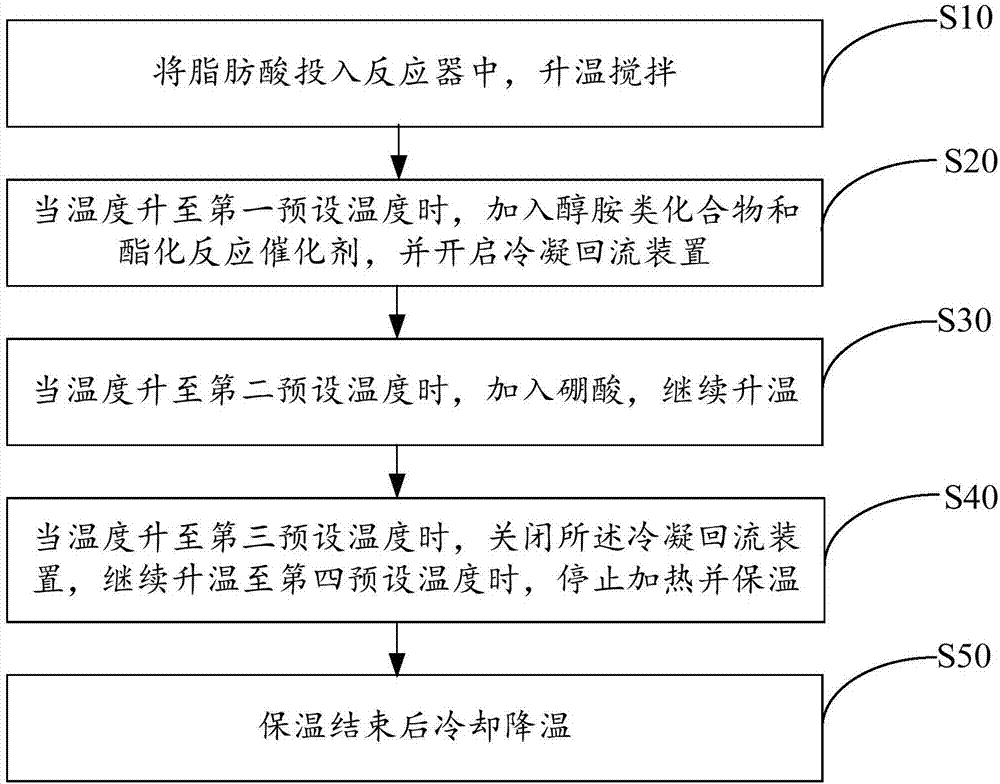

[0030] The present invention also proposes a method for preparing the above-mentioned antirust agent, wherein the method for preparing the antirust agent includes the following steps:

[0031] Step S10, put the fatty acid into the reactor, heat up and stir;

[0032] In the industrial production process, the reactor can be equipped with reaction devices such as kettle reactors and stirring devices; when conducting experiments in the laboratory, it can be built with experimental equipment such as three-necked flasks, condenser tubes, and stirring rods. A simple reaction device to achieve the purpose of heating and stirring the reaction raw materials.

[0033] Step S20, when the temperature rises to the first preset temperature, add the alcohol amine compound and the esterification reaction catalyst, and open the condensation reflux device;

[0034] Step S30, when the temperature rises to the second preset temperature, add boric acid and continue to raise the temperature;

[00...

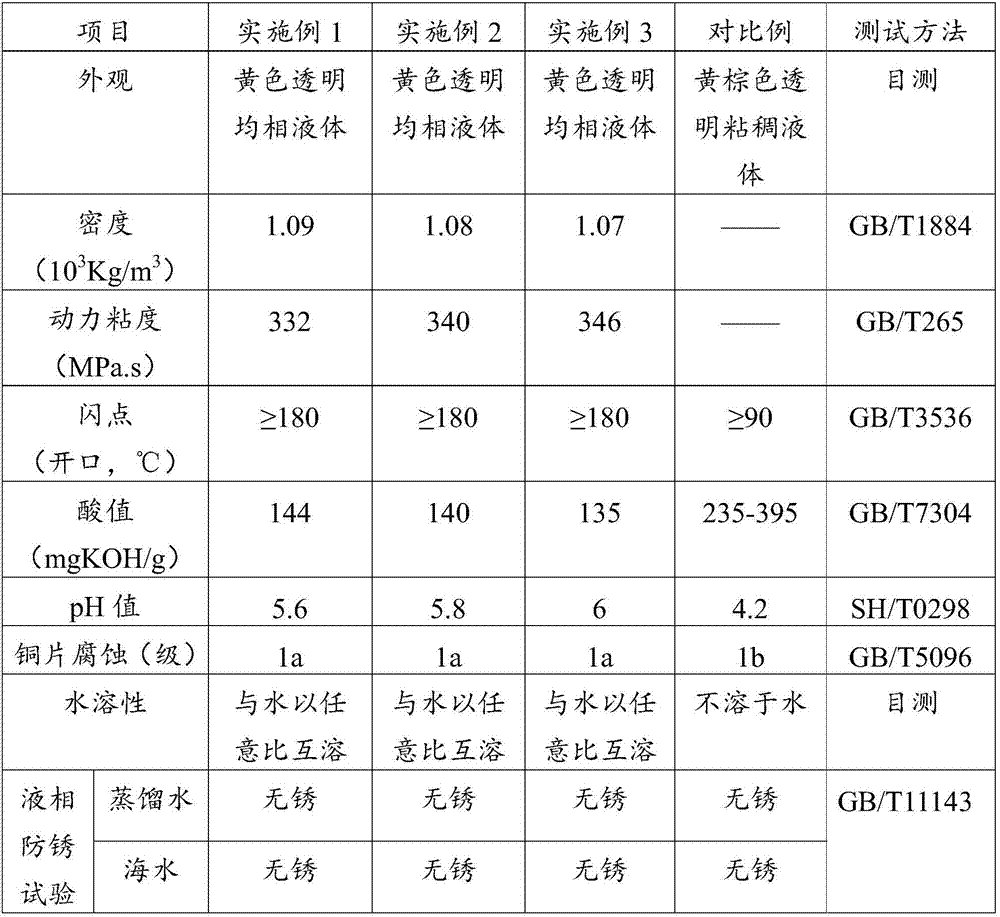

specific Embodiment 1

[0041] (1) Take octanoic acid, triethanolamine, boric acid and tetra-n-butyl titanate, wherein, the molar ratio of octanoic acid, triethanolamine and boric acid is 5:2:1, and the quality of tetra-n-butyl titanate is octanoic acid, triethanolamine and 1.0% of the total mass of boric acid; then octanoic acid is dropped into a three-necked flask, and the heating device and the stirring device are opened to heat up and stir;

[0042] (2) When the temperature rises to 75°C, add the weighed triethanolamine and tetra-n-butyl titanate, and open the water pipe connected to the condensation pipe to condense and reflux;

[0043] (3) When the temperature rose to 105°C, add the boric acid weighed and continue to heat up;

[0044] (4) When the temperature rises to 135°C, close the water pipe connected to the condensation pipe, and stop heating when the temperature continues to rise to 139°C, and keep it warm for 30 minutes;

[0045] (5) After the heat preservation is completed, turn on the...

specific Embodiment 2

[0046] (2) Take octanoic acid, triethanolamine, boric acid and tetra-n-butyl titanate, wherein, the molar ratio of octanoic acid, triethanolamine and boric acid is 2:1:1, and the quality of tetra-n-butyl titanate is octanoic acid, triethanolamine and 0.5% of the total mass of boric acid; then octanoic acid is dropped into a three-necked flask, and the heating device and the stirring device are opened to heat up and stir;

[0047] (2) When the temperature rises to 75°C, add the weighed triethanolamine and tetra-n-butyl titanate, and open the water pipe connected to the condensation pipe to condense and reflux;

[0048] (3) When the temperature rose to 105°C, add the boric acid weighed and continue to heat up;

[0049] (4) When the temperature rises to 135°C, close the water pipe connected to the condensation pipe, and stop heating when the temperature continues to rise to 139°C, and keep it warm for 30 minutes;

[0050] (5) After the heat preservation is completed, turn on the s...

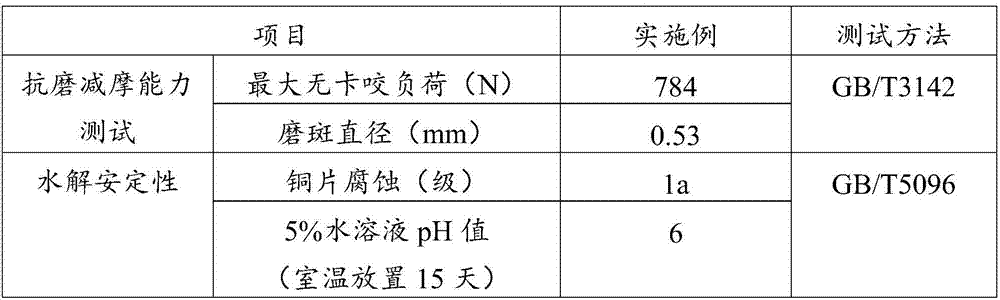

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com