Lactobacillus brevis capable of improving fermented flavor of fermented dough steamed bun and application thereof

A technology of Lactobacillus brevis and steamed bread, applied in the direction of bacteria, microorganism-based methods, microorganisms, etc., can solve the problem of no aromatic flavor substances, achieve rich and strong aroma, improve flavor, and moderate acid production ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Isolation and identification of Lactobacillus brevis strains in old dough

[0032] 1) Preparation of sample diluent and isolation of bacteria

[0033] Take 10 g of traditional fermented dough samples in a sterile homogenizing bag, and add 90 mL of sterile water; put the homogenizing bag in a homogenizer, and homogenize at 6 speeds for 5 minutes to make a 1:10 sample solution. Then use a 1 ml sterile pipette tip to absorb 1 ml of the sample treatment solution and add it to 9 ml of sterilized normal saline, shake and mix well and serve for 10 -2 Diluent; and so on, serially diluted to 10 -7 . Draw 0.1ml of 10 -5 、10 -6 、10 -7 Put the gradient dilution into the culture dish containing MRS agar medium, spread it evenly on the surface of the medium with a coating rod, and culture it anaerobically at 37°C for 48h.

[0034] The colonies of this characteristic strain are characterized by a size of 1 mm, round bulges, smooth and opaque surface, semi-dry, white. ...

Embodiment 2

[0044] Embodiment 2: Verification of strain fermentation characteristics

[0045] 1. Adaptability of Lactobacillus brevis in flour

[0046] Weigh 100g of wheat flour into an Erlenmeyer flask, add 200g of sterile water, shake and extract on a shaker at 20°C and 200rpm for 12h; centrifuge it at 500g at 4°C for 10min, and take the supernatant as wheat flour extract.

[0047] The cryopreserved Lactobacillus brevis of the present invention is inoculated in the MRS medium, cultivated at 37°C for 24h, and subcultured for 2 to 3 times in the MRS liquid medium, then 1.0mL of the bacterial solution obtained is centrifuged and washed with PBS (phosphoric acid salt buffer solution) and washed twice and resuspended in PBS; it was inoculated in wheat flour extract, cultured at 30°C for 24 hours, and the amount of bacteria was determined.

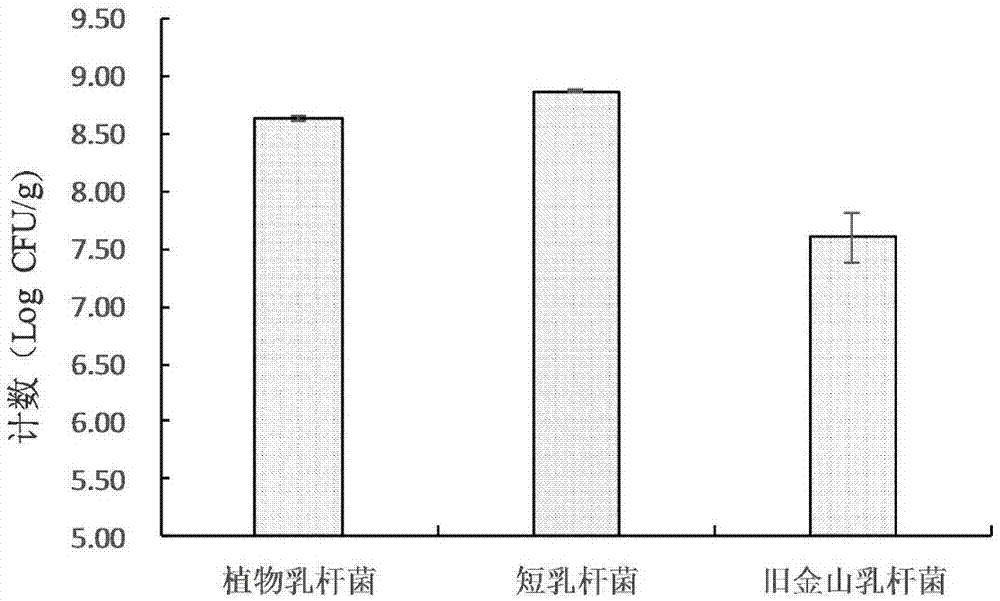

[0048] See the experimental results figure 1 , the results showed that the bacterial species of Lactobacillus brevis was maintained at 8.88 (Log CFU / g)...

Embodiment 3

[0060] Embodiment 3: the preparation of steamed bread

[0061] The production process of steamed buns is as follows: raw wheat flour (Wu Deli Flour Group, 910 high-gluten flour), water (Wuxi Huajing Piaozhilin Co., Ltd.), add sourdough and leavening agent, mix well and knead the dough to form a dough. Proof for 3-4 hours at a temperature of 30°C and a humidity of 80%; knead new flour at 12% (mass of flour) to seal the dough, knead it into shape, and proof at a temperature of 30°C and a humidity of 80% for 30-60 minutes; finish proofing The dough was steamed in a steamer for 20 minutes to obtain finished steamed buns.

[0062] Two groups of experiments were designed. Group A was steamed buns made by adding Lactobacillus brevis strains to make sourdough first, and Group B was steamed buns made by adding only commercial starter.

[0063] Specific steps are as follows:

[0064] (1) Production of sourdough: Accurately weigh 150g of wheat flour, add the activated strain to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com