Preparation method of aromatic hydrocarbon oil

An aromatic oil and alkane technology, applied in the field of aromatic oil preparation, can solve problems such as harsh conditions, poor conversion rate and product yield, and complexity, and achieve high octane number, improved engine power, and good anti-knock performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

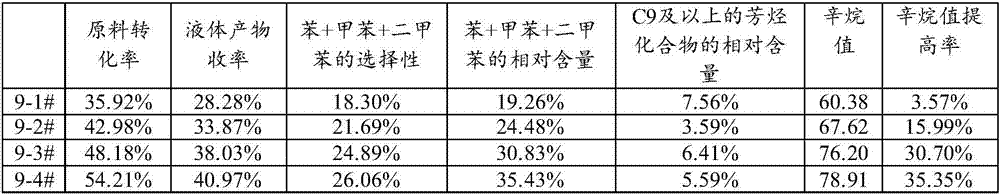

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of aromatic hydrocarbon oil, comprises the following steps:

[0024] In a methane-containing atmosphere, the raw oil rich in alkane components is subjected to an aromatization reaction under the action of an aromatization catalyst to obtain aromatic oil;

[0025] In the methane-containing atmosphere, the volume ratio of methane is 1% to 100%;

[0026] The aromatization catalyst is a metal-loaded ZSM-5 molecular sieve catalyst.

[0027] The preparation method of the present invention combines the methane atmosphere with the metal-loaded ZSM-5 molecular sieve catalyst, and the catalytic action of the catalyst and the activation of methane cooperate with each other, which can promote the aromatization reaction of the raw material oil, and effectively improve the conversion rate of the raw material and the yield of aromatics , especially improve the selectivity and yield of these light aromatic hydrocarbons of benzene, to...

Embodiment 1

[0041] Raffinated oil is used as raw material, and Zn-Ga / ZSM-5 molecular sieve is used as catalyst (the ratio of silicon to aluminum is 80, the mass ratio of Zn to ZSM-5 molecular sieve is 5%, and the mass ratio of Ga to ZSM-5 molecular sieve is 1%) , under a 100% methane atmosphere, the aromatization reaction is carried out in a continuous fixed-bed reactor; the mass space velocity of the raw oil is 3h -1 , the catalyst dosage is 1 g, the reaction temperature is 300° C., the reaction pressure is 5.0 MPa, and the reaction time is 60 min. After the reaction, aromatic oil is obtained. The obtained aromatic oil components were tested, and the results showed that the conversion rate of the raw oil was 45.86%, and the liquid product yield was 33.95%; among them, the selectivity of benzene, toluene and xylene was 15.59%, and the benzene, toluene in the aromatic oil The relative content of xylene and xylene is 18.74%, and the relative content of C9 and above aromatic compounds is 4.4...

Embodiment 2

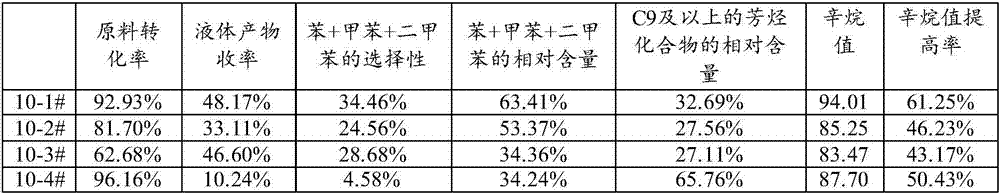

[0043] Raffinated oil is used as raw material, and Zn-Ga / ZSM-5 molecular sieve is used as catalyst (the ratio of silicon to aluminum is 80, the mass ratio of Zn to ZSM-5 molecular sieve is 5%, and the mass ratio of Ga to ZSM-5 molecular sieve is 1%) , under a 100% methane atmosphere, the aromatization reaction is carried out in a continuous fixed-bed reactor; the mass space velocity of the feedstock oil is 1.5h -1 , the amount of catalyst is 2g, the reaction temperature is 380°C, the reaction pressure is 5.0MPa, and the reaction time is 60min. After the reaction, aromatic oil is obtained. The obtained aromatic oil components were detected, and the results showed that the conversion rate of the raw oil was 92.93%, and the liquid product yield was 48.17%; among them, the selectivity of benzene, toluene and xylene was 34.46%, and the benzene, toluene in the aromatic oil The relative content of xylene and xylene is 63.41%, and the relative content of C9 and above aromatic compound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com