Liquid medicine vacuum negative-pressure filling tank

A vacuum negative pressure and filling tank technology, which is applied in the field of filling tanks and liquid medicine vacuum negative pressure filling tanks, can solve the problems of filling tank cleaning and filling inconvenience, so as to reduce the difficulty of filling and make it easy to pick and place , filling and cleaning convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings. Embodiments of the present invention include, but are not limited to, the following examples.

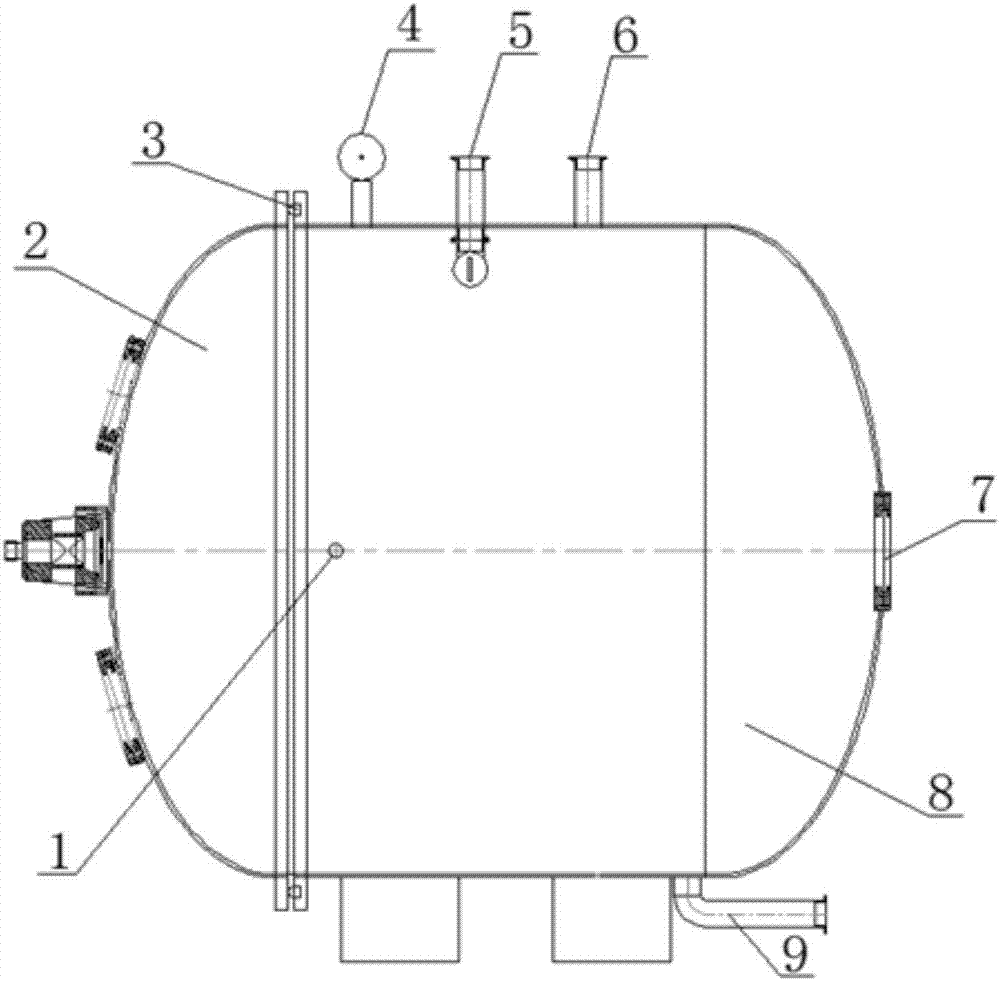

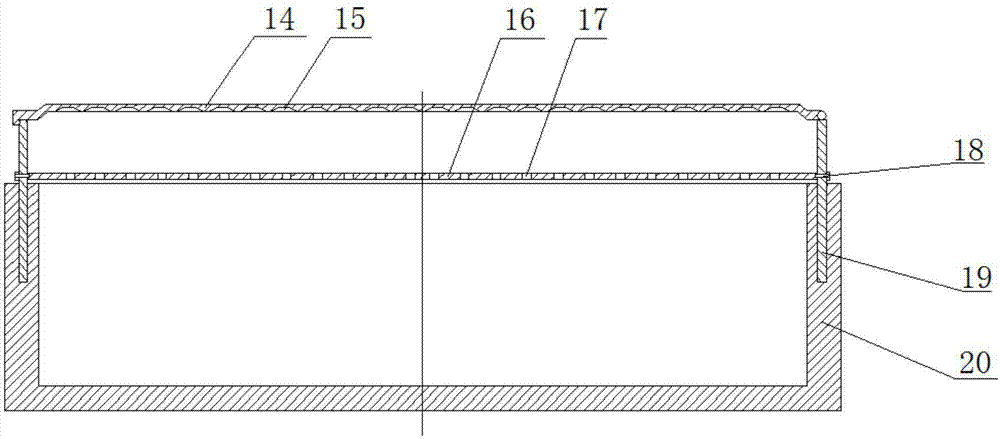

[0018] Such as Figure 1-2 The shown vacuum negative pressure filling tank for liquid medicine includes a tank body 8 placed horizontally, the upper part of the tank body 8 is provided with a vacuum negative pressure gauge 4, a cleaning interface tube 5 and a vacuuming interface tube 6, and the middle part is provided with a venting port 1. There is a sewage outlet 9 at the bottom. The tank body 8 is a cylindrical structure made of 304 stainless steel. One end of the tank body 8 is sealed, and the other end is a hemispherical cabinet door 2 that can be opened and closed, and the tank body 8 is sealed. The end and the hemispherical cabinet door 2 are all provided with observation mirror 7; said tank body 8 is also provided with a mobile frame 11, a plurality of tray assemblies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com