Continuous production method for laminated compression wood

A technology for compressing wood and production methods, which is applied in the direction of lamination, lamination devices, impregnated wood, etc., can solve the problems of undisclosed layered compressed wood connection production methods, etc., achieve selective directional densification, and improve the use of Performance and use price, the effect of improving actual production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

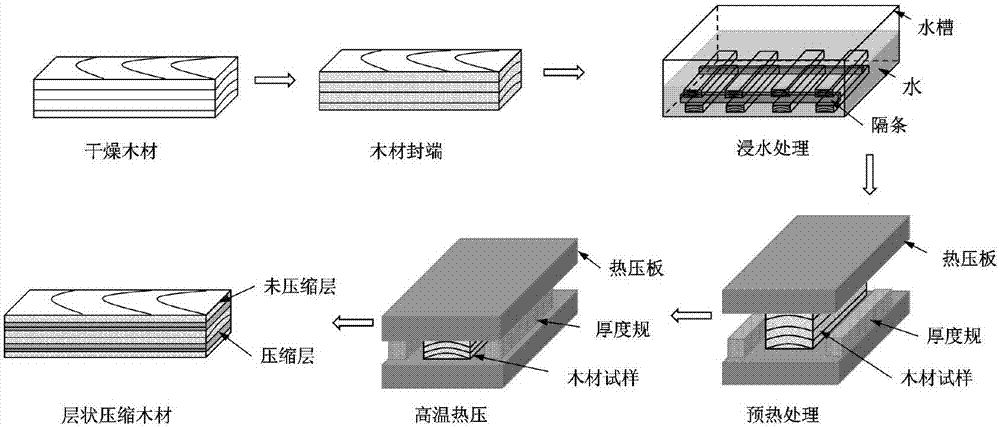

[0030] Example 1: Continuous production method of layered compressed wood, as attached figure 1 As shown,

[0031] The layered compressed wood is made from wood after drying wood, wood end-sealing, water immersion treatment, pre-heat treatment, high-temperature hot pressing (that is, compression treatment), and the method includes the following steps:

[0032] (1) According to actual production requirements, the logs are sawn into wood of corresponding size (or called boards, the same below), where the logs can be any tree species, preferably low-density plantation fast-growing wood. The wood is then dried in an atmospheric environment or in a drying kiln or drying box, and the moisture content after drying is less than 20%, preferably the moisture content is less than 16%.

[0033] (2) After capping the water content of wood, paraffin and other hydrophobic materials with a moisture content of less than 16%, or directly soaking in water, the water temperature is 0-100℃, preferably 2...

Embodiment 2

[0043] The materials or equipment used in the present invention are as follows:

[0044] material:

[0045] a, the density is 0.20-0.70g / cm 3 Wood, or wood with a density of less than 0.70g / cm, including plantation fast-growing wood and natural forest wood, such as poplar and willow species, Chinese fir, paulownia, cedar and other domestic fast-growing woods, as well as all imported fast-growing woods;

[0046] b. The wood processing plant board can be chord plate, chord radial plate, radial plate, preferably chord plate;

[0047] c. The thickness is 0.5-500mm, and can also be any processable thickness, preferably 1-150mm;

[0048] d. Planing and sanding the sawn wood board surface to make the surface smooth, or the sawn board does not have the surface leveling treatment;

[0049] e. End-capping agent: paraffin and other hydrophobic materials;

[0050] f. Softener: water, ammonia, alkaline aqueous solution and one or more of imines, ketones, ethers, alcohols, nitriles, amides, esters, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com