Inclined punch press falling material collecting box

A collection box, inclined technology, applied in the field of inclined punch blanking collection box, to achieve high work efficiency, low manufacturing cost, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

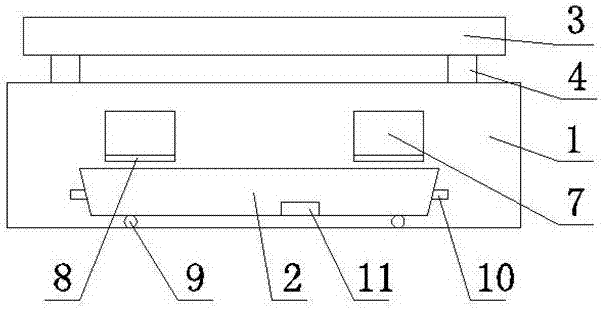

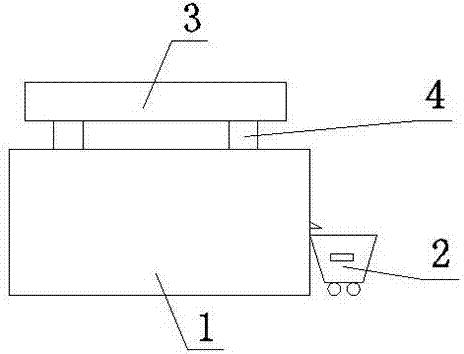

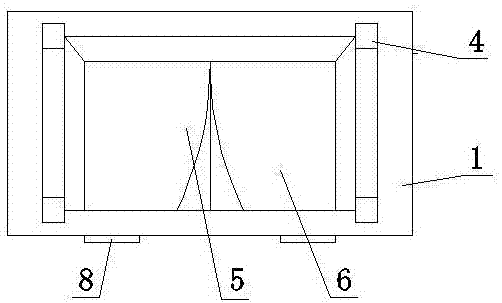

[0017] Such as Figure 1~Figure 3 As shown, a kind of tilting punch blanking collection box includes a box body 1 and a collection tank car 2, the top surface of the box body 1 is provided with a concave area 5, and the front surface of the box body 1 is provided with A plurality of discharge notches 7, the concave area 5 is obliquely downward along the direction of the discharge notch 7 to form the inclined surface 6 of the concave area 5, the lower bottom edge of the inclined surface 6 of the concave area 5 and the discharge notch 7 are connected, and the inner concave area 5 is divided into multiple sub-regions according to the number of discharge slots 7. A discharge transition piece 8 is fixedly installed at the outlet of the discharge slot 7, and a collection box is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com