Low-cost mineral processing technology for high-silicon high-calcium magnesite

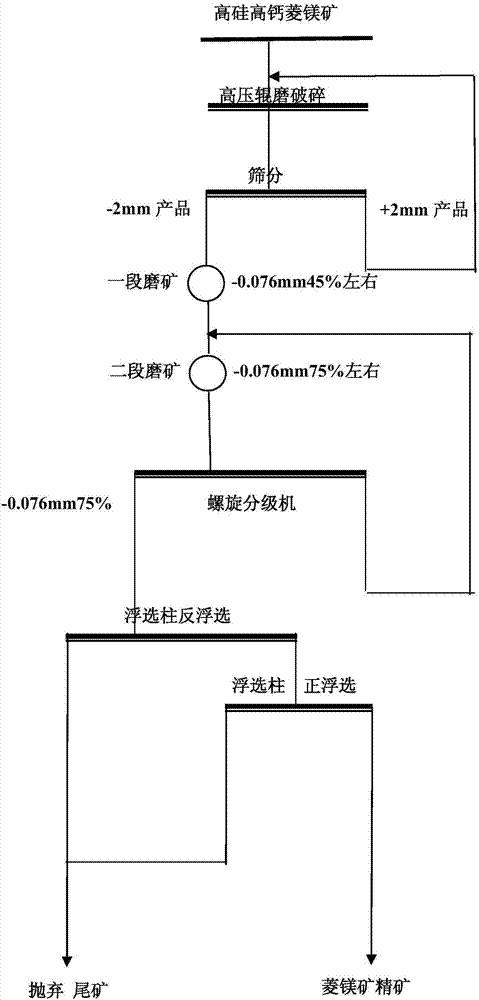

A high-calcium magnesite, low-cost technology, applied in the field of beneficiation, can solve the problems of vulnerable equipment, large floor space, small processing capacity, etc., and achieve the effect of saving basic investment, less floor space, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention is a low-cost beneficiation process for high-silicon and high-calcium magnesite. The main chemical components of the processed high-silicon and high-calcium magnesite raw ore are: 46.20% of magnesium oxide, 2.28% of silicon dioxide, and 1.92% of calcium oxide. High-pressure roller mill, to obtain medium crushing products with a particle size of less than 2mm, and feed the medium crushed products with a particle size of less than 2mm into a first-stage grid-type ball mill for grinding, and the particle size of the first-stage grid-type ball mill is -0.076mm 40%, the particle size of the first-stage grid ball mill is -0.076mm, accounting for 40%, and the grinding products are fed into the closed-circuit grinding operation composed of the second-stage grid-type ball mill and the spiral classifier, and the particle size of the second-stage grid-type ball mill is -0.076mm 70-80% of the overflow product enters the next process of flotation, and the spiral...

Embodiment 2

[0031] The present invention is a low-cost beneficiation process for high-silicon and high-calcium magnesite. The main chemical components of the processed high-silicon and high-calcium magnesite raw ore are: 45.80% of magnesium oxide, 2.28% of silicon dioxide, and 1.50% of calcium oxide. High-pressure roller mill, the product particle size is below 2mm, and the medium crushing product with a product particle size below 2mm is obtained, and the medium crushing product with a particle size below 2mm is fed into a first-stage grid-type ball mill for grinding, and the grinding product of the first-stage grid-type ball mill The particle size is -0.076mm, which accounts for 45%, and the particle size of the first-stage grid type ball mill is -0.076mm, which accounts for 45%. The ball mill particle size is -0.076mm, accounting for 70-80% of the overflow product enters the next process of flotation, and the spiral classifier returns to the second-stage ball mill; the second-stage latt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com