A kind of production method of hollow silicone rubber composite insulator

A technology of composite insulators and production methods, applied in the direction of insulators, electrical components, circuits, etc., can solve problems such as danger, achieve the effects of reducing the impact of high temperature, simple and convenient overall process, and good surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

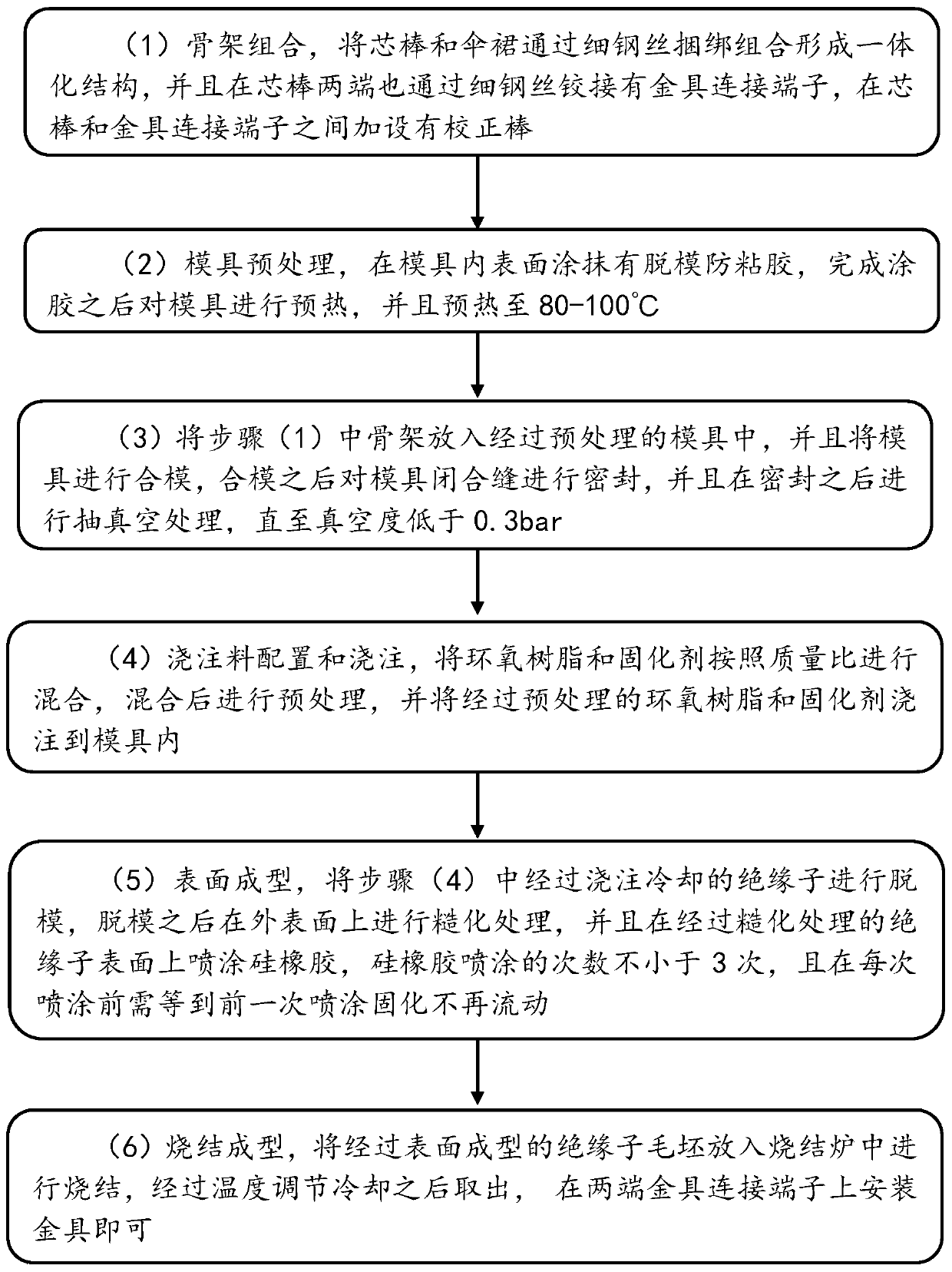

[0024] Such as figure 1 Shown, a kind of production method of hollow silicon rubber composite insulator, it comprises the steps:

[0025] (1) Skeleton combination, the mandrel and the shed are bound and combined by thin steel wires to form an integrated structure, and the two ends of the mandrel are also hinged with metal fittings connecting terminals through thin steel wires, and there is an additional set between the mandrel and the fittings The construction of the mandrel in the combination of the correction rod and the skeleton needs to form a hollow hollow structure inside, and there are movable ends at either end or both ends to facilitate the matching of the mold;

[0026] (2) Mold pretreatment, apply mold release anti-sticking glue on the inner surface of the mold, preheat the mold after the glue is applied, and preheat to 80-100°C;

[0027] (3) Put the skeleton in step (1) into the pretreated mold, and mold the mold, seal the mold closing seam after mold closing, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com