Dry-hanging structure and construction method for building ceramic large plank curtain wall

A technology of architectural ceramics and curtain walls, applied in building components, building structures, buildings, etc., can solve problems such as damage, failure to take into account the uniform distribution of force on back bolts, etc., to avoid material aging and chemical material pollution Hidden dangers, reduction and avoidance of smashing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

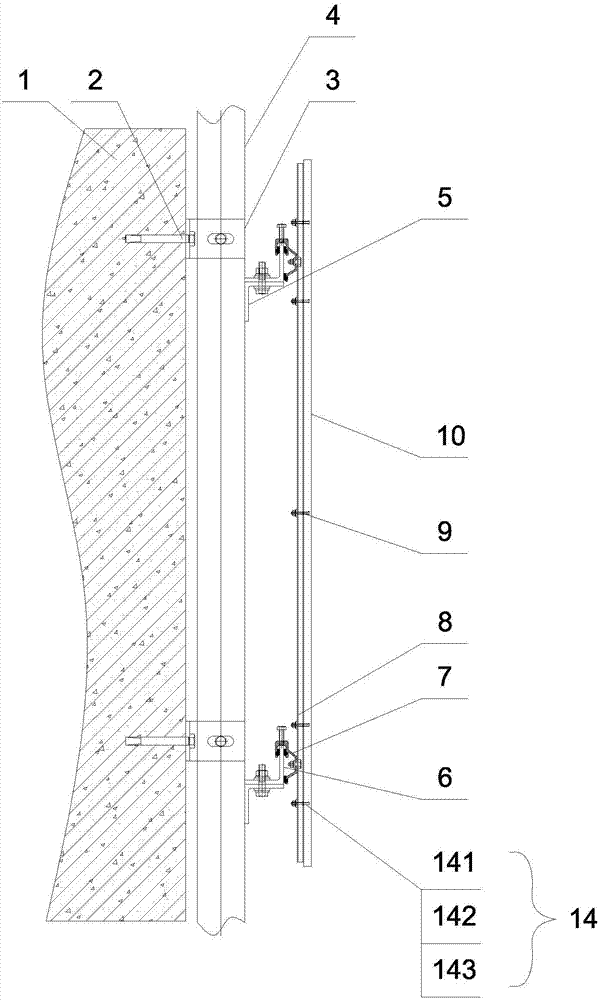

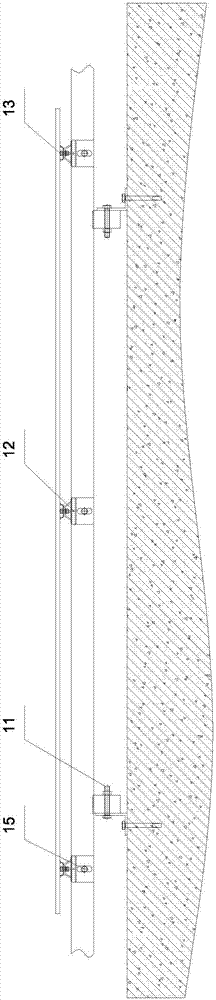

[0037] The invention relates to a dry-hanging structure of a building ceramic large-slab curtain wall and a construction method thereof.

[0038] The dry-hanging structure of the building ceramic large-slab curtain wall includes a keel 4, which is longitudinally fixed on the wall through a connecting component 3, such as figure 1 As shown, the bolt connection hole between the connection component 3 and the keel 4 is a long strip connection hole, so that the bolt connection position between the connection component 3 and the keel has an adjustable space, and is fixed by the bolt 11, and the elastic bolt can adjust the position of the keel. plane position. The connection assembly is fixed on the wall through expansion bolts 2 .

[0039] A crossbeam 5 is installed on the outer side of the keel 4 relative to the wall, and the crossbeam 5 and the keel 4 are vertically arranged to form a frame structure, which can be fixed by welding. The crossbeam 5 is connected with a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com