Device and method for oxidizing modification of sintering semi-dry desulfurization ash

A technology of a semi-dry desulfurization and oxidation device, which is applied in the field of sintered and semi-dry desulfurized ash oxidation modification devices, can solve the problems of poor efficiency of semi-dry desulfurization and oxidation, and achieves speeding up the oxidation efficiency, increasing the content, and avoiding SO2. escape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

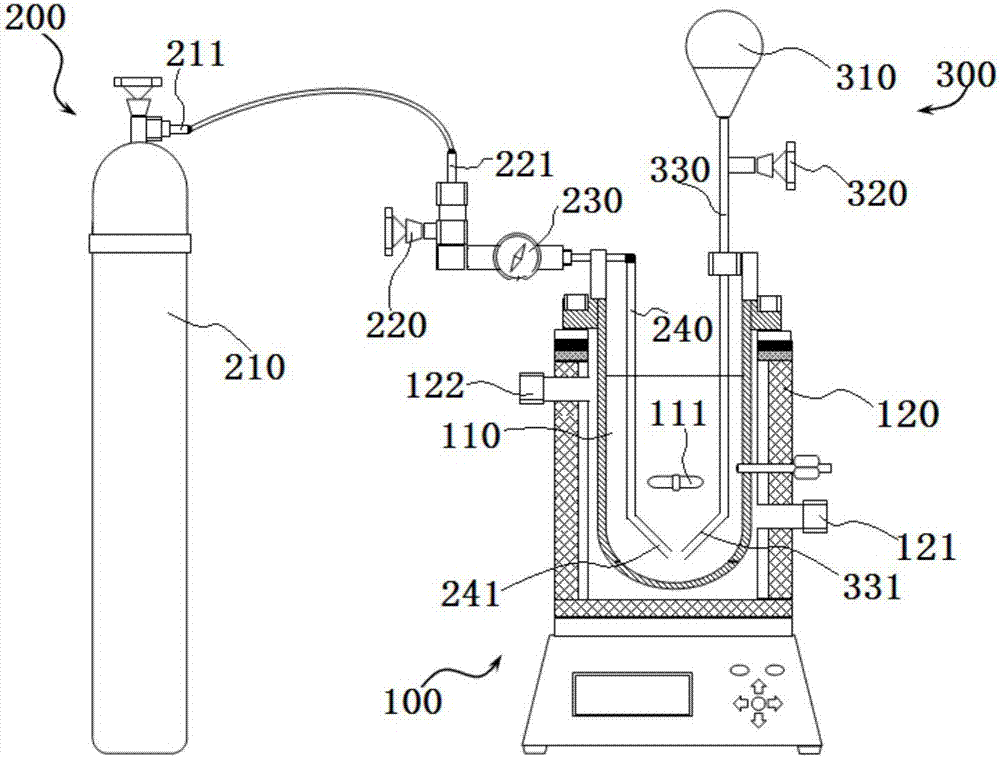

[0048] Such as figure 1 As shown, a sintered semi-dry desulfurization ash oxidation device of the present invention includes a reaction unit 100, a gas supply unit 200 and an oxygen promoter injection unit 300, wherein the reaction unit 100 includes a reactor cavity 110, and the reactor cavity 110 It is used to contain the oxidized desulfurization ash mixture, and the middle part of the reactor cavity 110 is provided with a cavity stirrer 111, which is used to stir the desulfurization ash mixture in the reactor cavity 110 to promote uniform reaction The reactor cavity 110 is provided with a thermocouple 112, which is used to monitor the temperature of the mixed liquid in the reactor cavity 110. Above-mentioned gas supply unit 200 comprises gas supply bottle 210, gas control valve 220, flowmeter 230 and gas pipeline 240, and gas supply bottle 210 is connected with gas pipeline 240 through gas control valve 220, and the gas cylinder outlet 211 of gas supply cylinder 210 is conne...

Embodiment 2

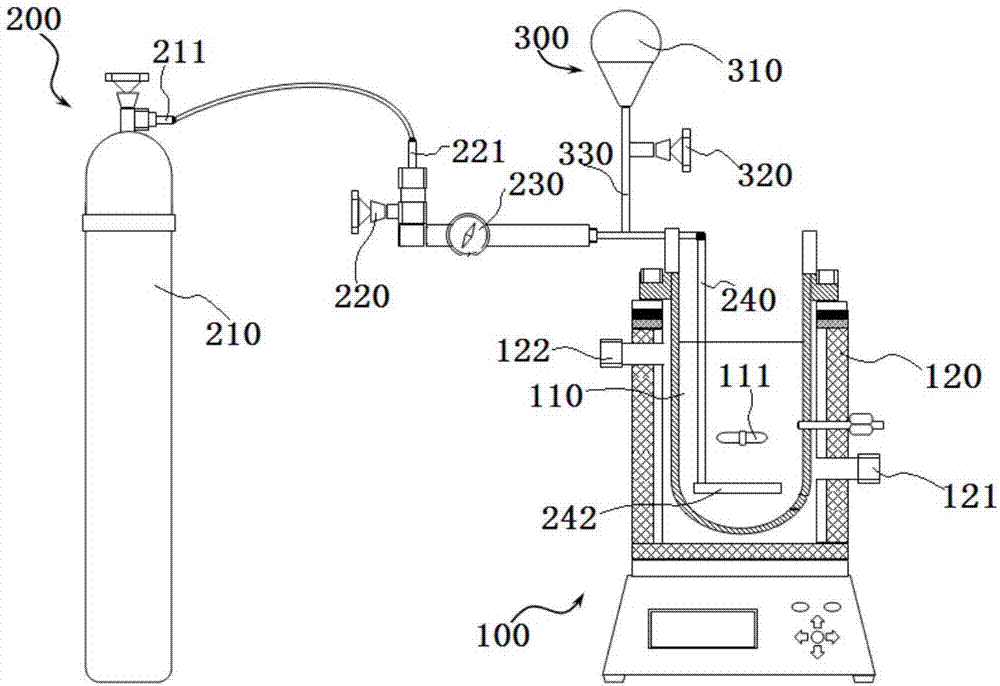

[0068] The basic content of this embodiment is the same as embodiment 1, the difference is: as figure 2 As shown, a sintered semi-dry desulfurization ash oxidation device of this embodiment, the liquid pipeline 330 extends into the gas pipeline 240, and the oxygen promoter solution in the oxygen promoter container 310 enters the reactor driven by the gas supply unit 200 The bottom of the cavity 110. The bottom of the liquid pipeline 330 is provided with a bubble generator 242 , and the bubble generator 242 makes the gas and oxygen promoter solution evenly distributed in the reactor inner cavity 110 . Make the oxygen promoter solution in the process of combining the desulfurization ash, the CaSO in the desulfurization ash 3 After forming an ion state and entering the solution, the oxygen-containing gas can quickly combine with the H in the solution state 2 SO 3 combined, and an oxidation reaction occurs to produce SO 4 2- , thereby increasing the rate of the reaction.

...

Embodiment 3

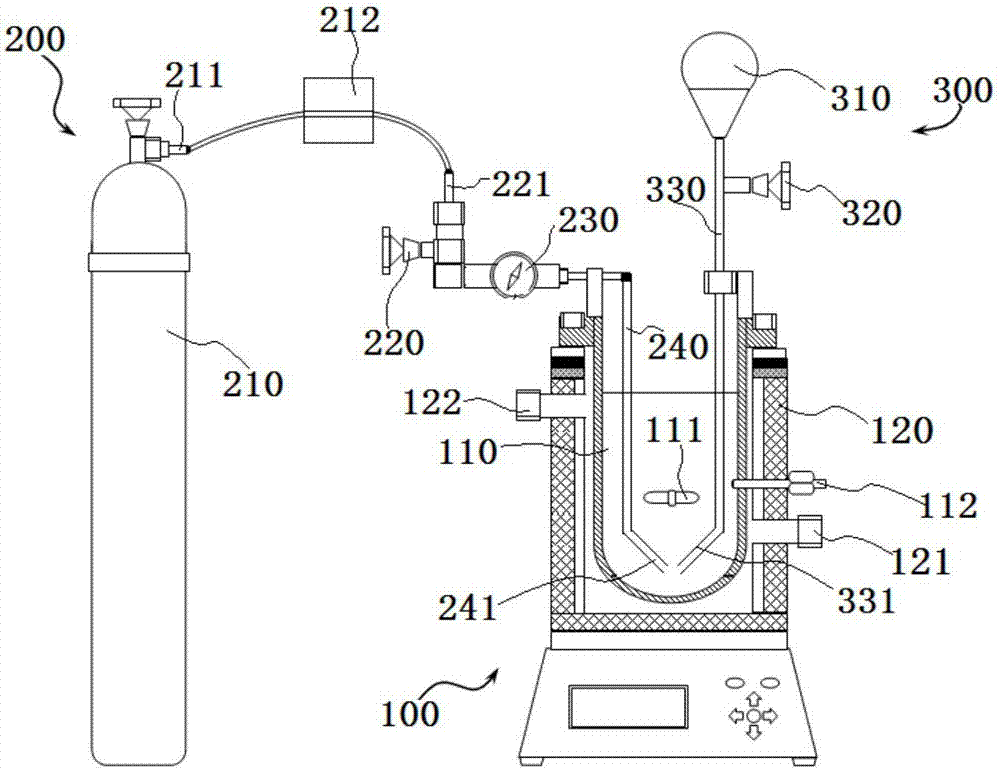

[0071] The basic content of this embodiment is the same as embodiment 1, the difference is: as image 3 As shown, the pipeline between the gas supply bottle 210 and the gas control valve 220 in this embodiment is provided with a gas cooling mechanism 212, and the gas cooling mechanism 212 is used to cool the gas in the pipeline so that it is blown into the desulfurization ash mixed liquid The gas is a low-temperature gas, and the gas temperature is 0°C, which promotes the reduction of the reaction temperature and improves the reaction interface during the oxidation of calcium sulfite, thereby greatly improving the reaction efficiency. The acidic auxiliary agent in this embodiment is composed of oxalic acid and dichloroacetic acid, and the mass ratio of oxalic acid and dichloroacetic acid is 2:1, and the oxygen auxiliary agent in this embodiment is composed of oxalic acid and dichloroacetic acid. The use of the oxygen promoter of the present invention greatly improves the oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com