Tubular product straightening and discharging machine

A straightening and pipe technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of decreased mechanical performance, expensive equipment, unsuitable for straightening small-diameter coiled pipes, etc., and achieves good isometric and production efficiency. High, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

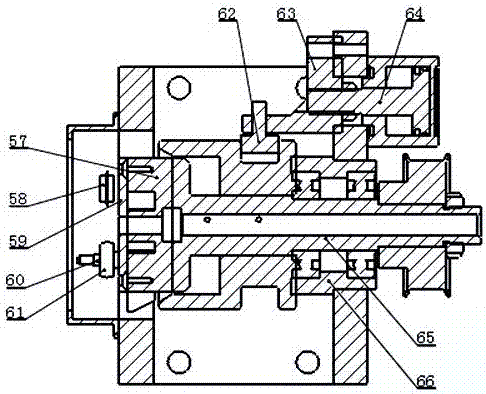

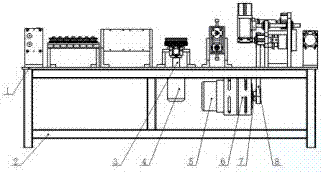

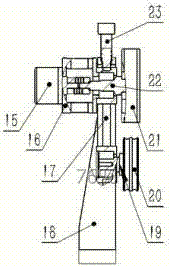

[0016] as attached figure 1 As shown, each device of the present invention is provided with a guiding device, a straightening device, a traction device, a stroke counting coding device, a cutting and pulling device, and a clamping device successively on the frame panel. as attached figure 2 As shown, the coiled linear metal pipe passes through the guide wheels in the horizontal direction and the vertical direction. as attached Figure 4 As shown, the guided pipes are straightened sequentially through the horizontal and vertical straightening wheels. as attached Figure 5 As shown, the straightened pipes pass through the nylon driving and driven wheels with R grooves respectively, and the conveying motor 4 drives the conveying gear to rotate and drive the pipes to move forward. Drive the slide plate 40 through the conveying cylinder 38 to adjust the gap between the main and driven wheels to achieve moderate clamping of the pipe, push the pipe into the stroke counting encod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com